On-line repairing method for weld defects of in-service GIS shell of transformer substation

A repair method and substation technology, applied in the electric power field, can solve problems such as uncontrollable air leakage, lack of SF6 gas, and reduce operation and maintenance costs, and achieve the effects of improving efficiency and economy, good fatigue resistance, and reducing corrosion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

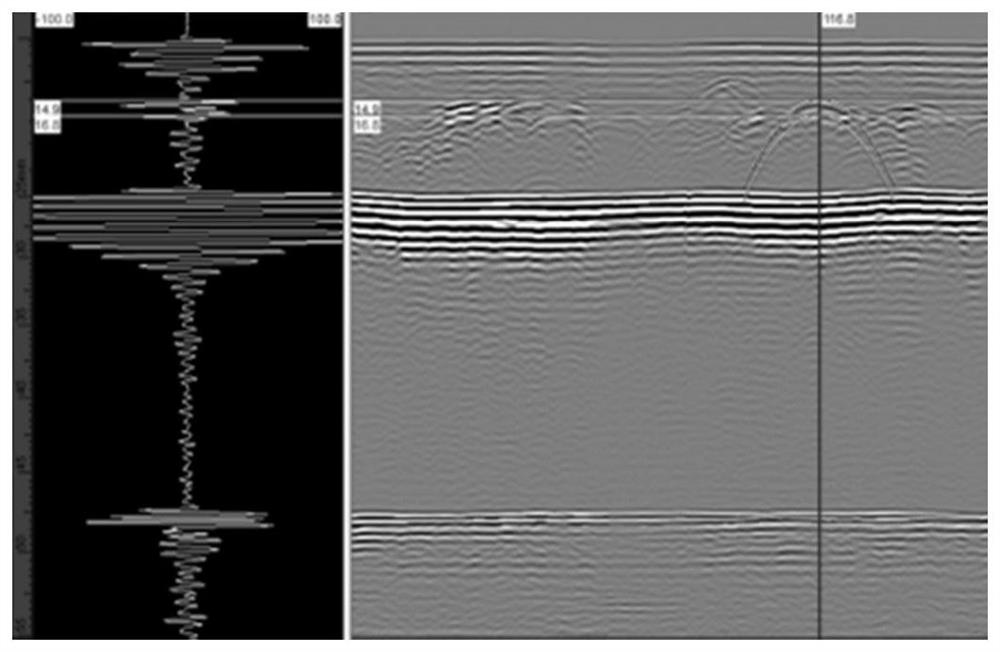

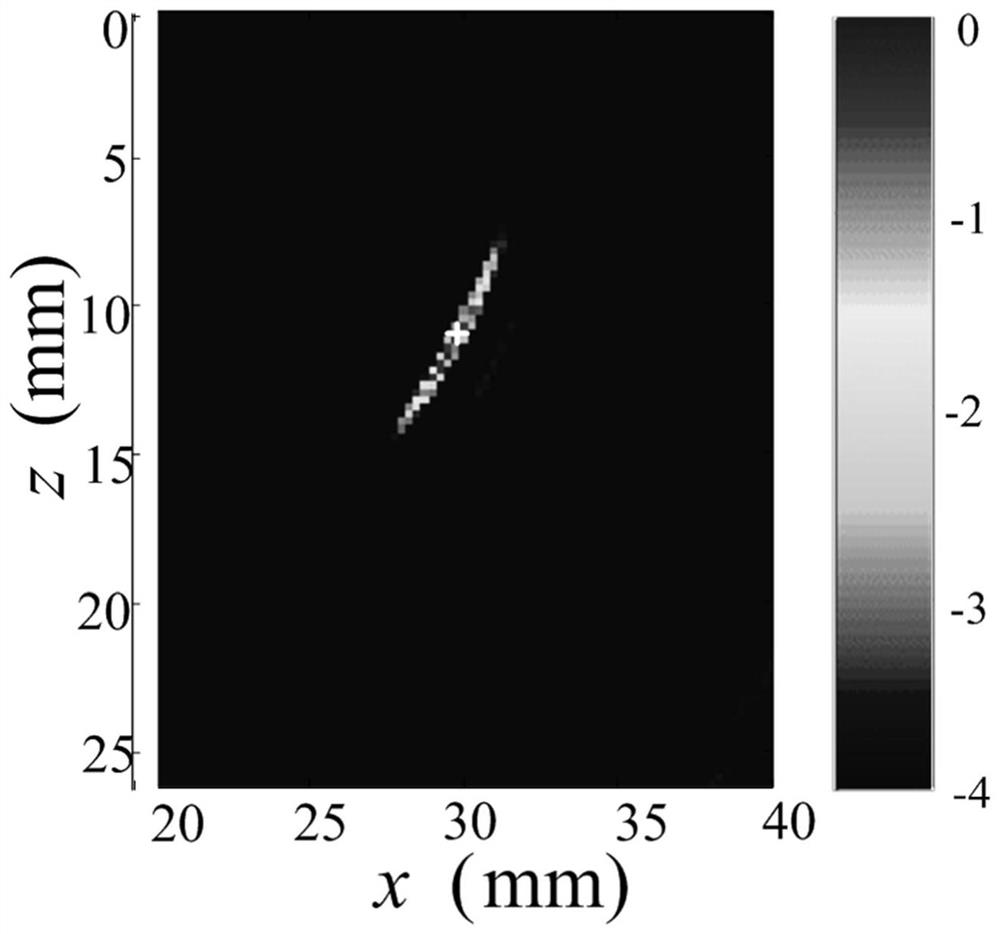

[0061] Concrete implementation of the GIS shell surface mounted on the SF 6 Air pressure sensor, and GIS housing has SF 6 Infrared imaging leak detectors or laser imaging leak detectors, as well as portable digital ray detectors and ultrasonic flaw detectors.

[0062] The main body of the concrete GIS housing is a straight cylinder in the middle, symmetrical flanges are arranged at both ends of the straight cylinder, and there are girth welds and straight welds on the surface.

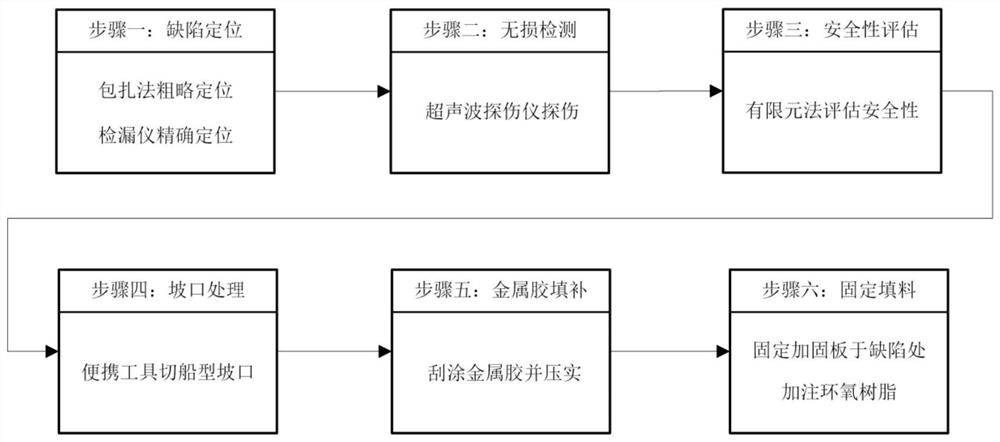

[0063] Such as figure 1 Shown, embodiment of the present invention and implementation thereof are as follows:

[0064] Defect location in step 1:

[0065] When the GIS equipment is running, a gas pressure sensor is installed in the inner cavity of the GIS shell, and the gas pressure sensor detects the air pressure, and then detects the SF 6 Whether the gas is le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com