Variable Capacity Vane Pump

A vane pump, capacity technology, applied in rotary piston pumps, pumps, pump components, etc., can solve problems such as pressure rise, achieve the effect of smooth compression speed and suppress shock pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

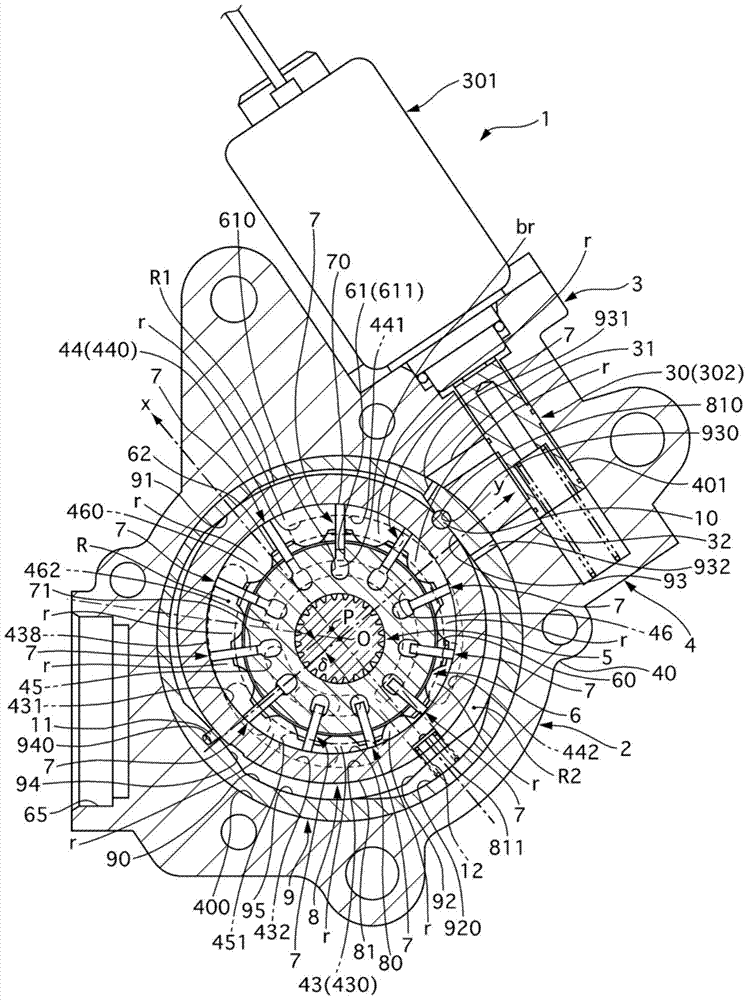

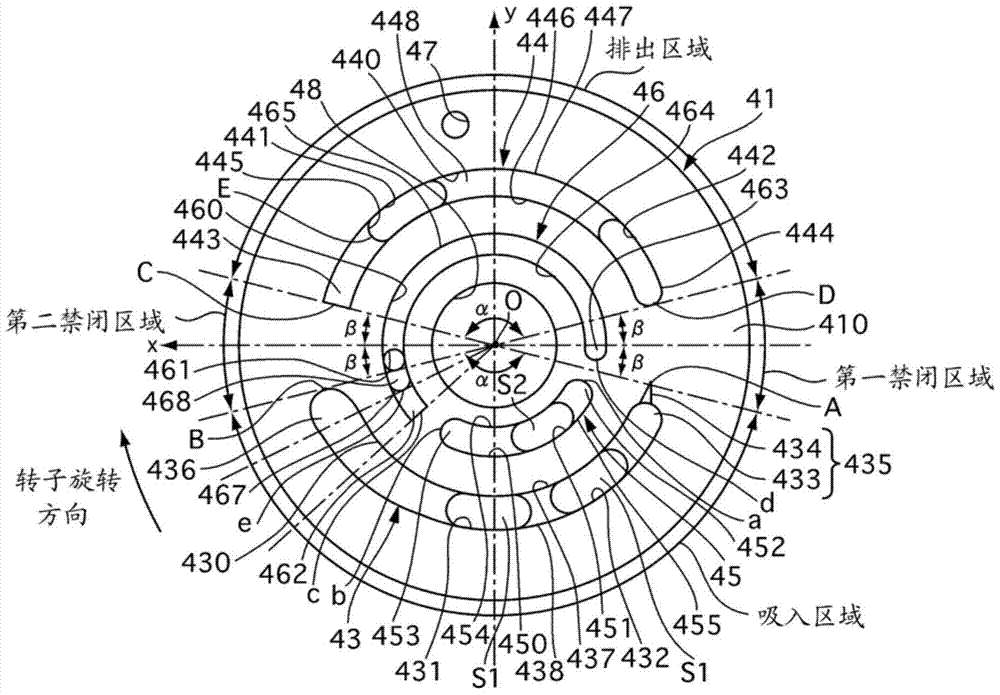

[0062] [Structure of Variable Capacity Vane Pump]

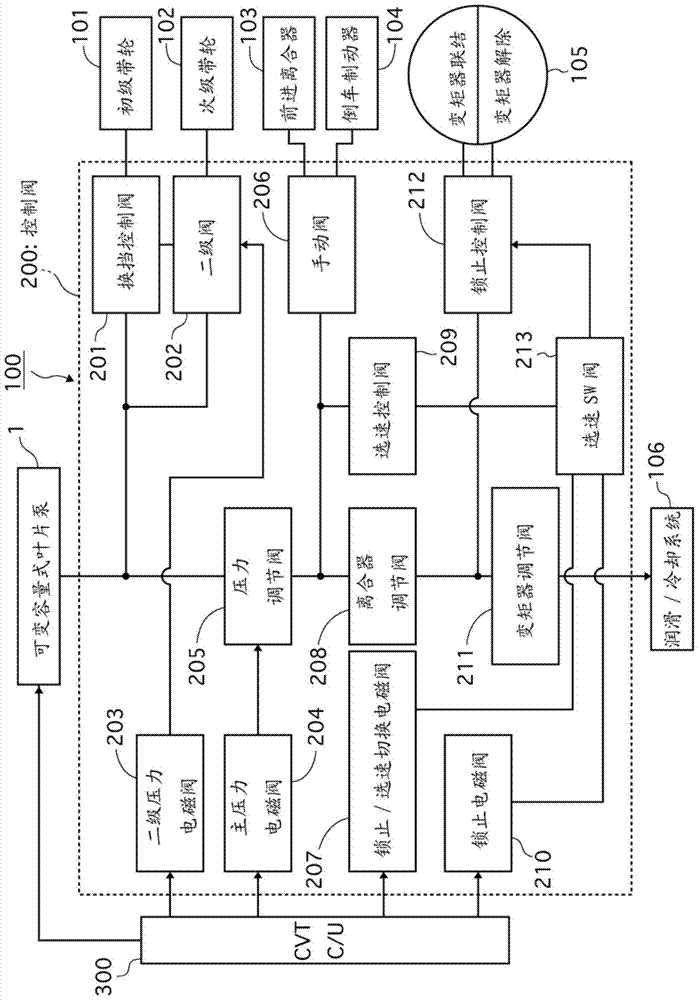

[0063] figure 1 It is a block diagram showing an example of a belt-type continuously variable transmission (CVT) 100 to which the variable displacement vane pump (hereinafter referred to as "vane pump") 1 of Embodiment 1 is applied. The outline of the vane pump (hereinafter referred to as "vane pump") 1 will be described. Vane pump 1 is used as a hydraulic pressure supply source for CVT 100 .

[0064] The vane pump 1 is driven by a crankshaft (not shown) of an internal combustion engine (engine), and sucks in / discharges a working fluid. Hydraulic oil, specifically, ATF (Automatic Transmission Fluid) is used as the working fluid. Hydraulic fluid (ATF) has a large elastic coefficient and a property in which the pressure changes greatly with a small change in volume.

[0065] In the control valve 200, various valves 201 to 213 controlled by the CVT control unit 300 are provided. The hydraulic oil discharged from the vane pu...

Embodiment 2

[0214] Figure 10 It is a graph showing the rate of change of the cam profile radius with respect to the angle for defining the stator profile when the stator eccentricity in Example 2 is the smallest.

[0215] In Example 2, such as Figure 10 As shown, the stator 8 differs from the first embodiment in that the rate of change of the cam profile radius has a negative value at the point where the stator profile definition angle is 180 degrees when the eccentricity δ of the stator 8 is the smallest.

[0216] The action of Example 2 will be described.

[0217] In the case where the stator 8 is formed such that when the stator eccentricity is the largest, the cam profile radius change rate temporarily decreases on the second confinement area side and then increases again, the smaller the eccentricity δ, the more the compression rate on the second confinement area side is suppressed or The larger the expansion ratio, the weaker the compression during high-speed rotation, and it may ...

Embodiment 3

[0223] Figure 11 It is a graph showing the change rate of the cam profile radius with respect to the angle for defining the stator profile when the stator eccentricity amount is maximum in Example 3.

[0224] In Example 3, such as Figure 11 As shown, the stator 8 is formed such that when the eccentric amount δ of the stator 8 is the largest, the maximum value when the cam profile radius change rate increases again after a temporary decrease is a negative value on the side of the second confinement area. 2 different.

[0225] The action of Example 3 will be described.

[0226] The greater the maximum value of the cam profile radius change rate when the cam profile radius change rate increases again, the larger the expansion rate is when the eccentricity δ is small. Therefore, in Example 3, by setting the cam profile radius change rate at which the maximum value is a negative value, it is possible to suppress Expansion with a small eccentricity δ can suppress cavitation dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com