A kind of low expansion speed nanoscale water-absorbing microsphere and preparation method thereof

A nano-scale, low-expansion technology, applied in the direction of nanotechnology, chemical instruments and methods, drilling compositions, etc., can solve the problems that polymer microspheres cannot be prepared, and achieve a small particle size distribution range, low viscosity, excellent dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

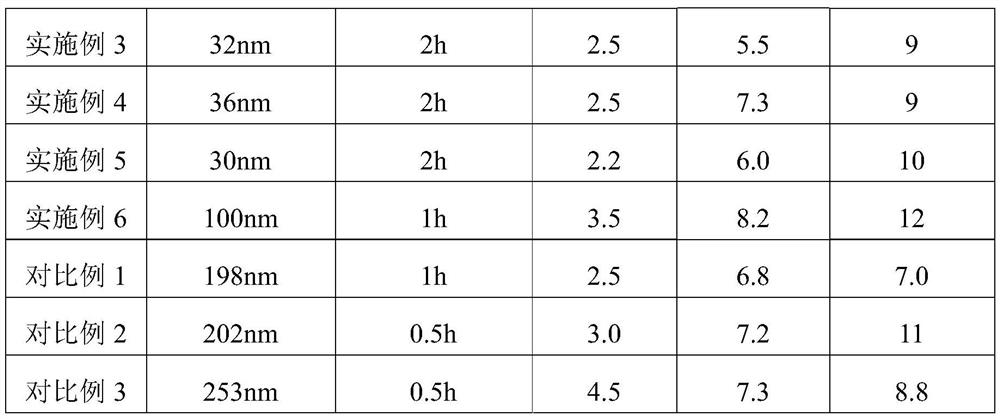

Examples

preparation example Construction

[0033] The invention provides a method for preparing nanoscale water-absorbing microspheres with low expansion speed. The preparation raw materials include the following components: 20-100 parts by weight of acrylamide, 50-150 parts by weight of acrylic acid, 0.5-3 parts by weight of hydrophobic monomer, cationic 10-20 parts by weight of monomer, 0.2-1.5 parts by weight of crosslinking agent, alkaline substance, 310-430 parts by weight of water, 80-200 parts by weight of emulsifier, 240-350 parts by weight of oily solvent, and 0.001-0.5 parts by weight of initiator 20-25 parts by weight of nonylphenol polyoxyethylene ether. The preparation method comprises the following steps:

[0034] (1) Prepare the aqueous phase solution: mix acrylamide, acrylic acid, cationic monomer, crosslinking agent and water evenly, and then add alkaline substances to obtain the aqueous phase mixed liquid. The cationic monomer used can be selected from any one or more of methacryloyloxyethyltrimethyl...

Embodiment 1

[0040] The preparation raw materials include the following components: 80 parts by weight of acrylamide, 120 parts by weight of acrylic acid, 2 parts by weight of p-hydroxystyrene, 10 parts by weight of methacryloyloxyethyltrimethylammonium chloride, N,N-methylene 0.4 parts by weight of bisacrylamide, 0.6 parts by weight of vinyltriethoxysilane, 67 parts by weight of sodium hydroxide, 310 parts by weight of water, 10 parts by weight of Tween 81110 parts by weight, 8040 parts by weight of Span, 240 parts by weight of heptane, azo 0.3 parts by weight of diisobutyronitrile, 0.02 parts by weight of potassium persulfate, 0.03 parts by weight of sodium bisulfite, and 22 parts by weight of nonylphenol polyoxyethylene ether.

[0041] The preparation method comprises the following steps: after thoroughly mixing acrylamide, acrylic acid, cationic monomer, cross-linking agent and water, adjusting the pH value to 6.9 with sodium hydroxide to obtain the water phase. Mix the oily solvent, h...

Embodiment 2

[0044] The preparation raw materials include the following components: 50 parts by weight of acrylamide, 150 parts by weight of acrylic acid, 1 part by weight of 1-octadecene, 15 parts by weight of acryloyloxyethyltrimethylammonium chloride, N,N-methylenebis 0.3 parts by weight of acrylamide, 0.9 parts by weight of vinyltriethoxysilane, 85 parts by weight of sodium hydroxide, 350 parts by weight of water, 8190 parts by weight of Tween, 30 parts by weight of Span 80, 290 parts by weight of hexane, azo 0.2 parts by weight of diisobutyronitrile, 0.1 parts by weight of potassium persulfate, 0.05 parts by weight of sodium bisulfite, and 23 parts by weight of nonylphenol polyoxyethylene ether.

[0045] The preparation method comprises the following steps: after thoroughly mixing acrylamide, acrylic acid, cationic monomer, cross-linking agent and water, adjusting the pH value to 6.8 with sodium hydroxide to obtain the water phase. Mix the oily solvent, hydrophobic monomer and emulsif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com