Temperature difference power generation system and working method thereof

A thermoelectric power generation and electricity storage technology, applied in generators/motors, electrical components, lighting and heating equipment, etc., can solve the problems of thermoelectric power generation technology gaps in areas with large temperature differences between day and night, achieve cooling effect, improve long-term The effect of improving the thermoelectric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

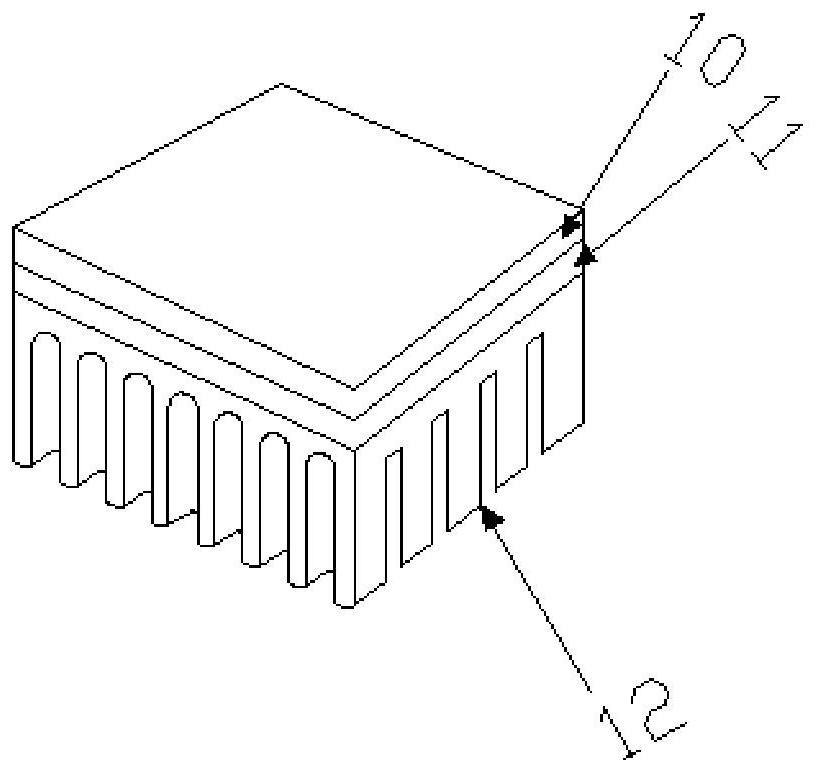

[0044] see image 3 , is the main component of the thermoelectric power generation system in this embodiment, that is, the thermoelectric power generation unit 1, including a thermoelectric power generation chip 11 that converts temperature difference into electric energy, a heat dissipation silicon grease pad for increasing heat dissipation and increasing temperature difference, and a heat dissipation device that conducts heat by dissipating heat from a heat source Black heat sink 12.

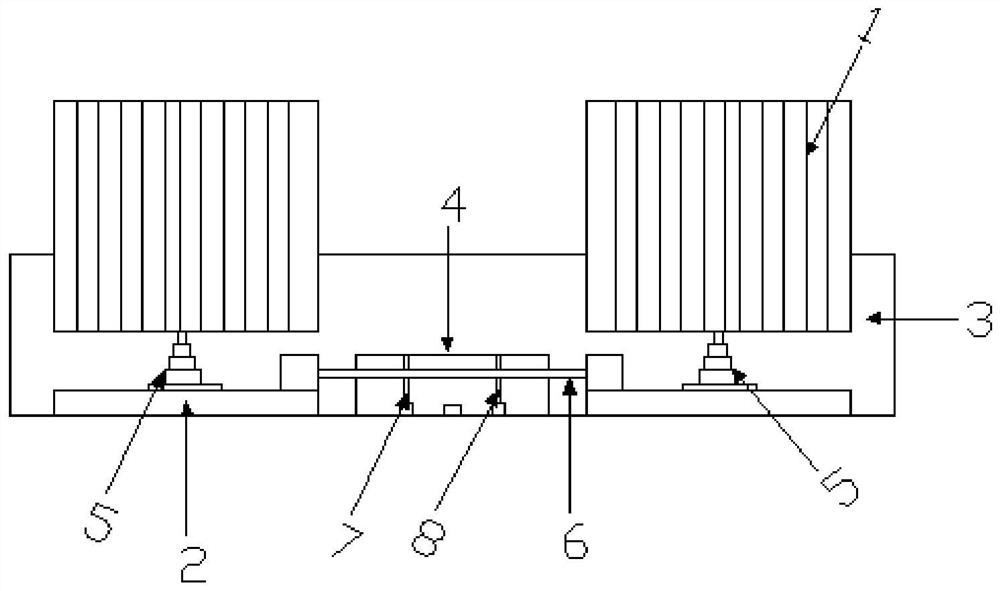

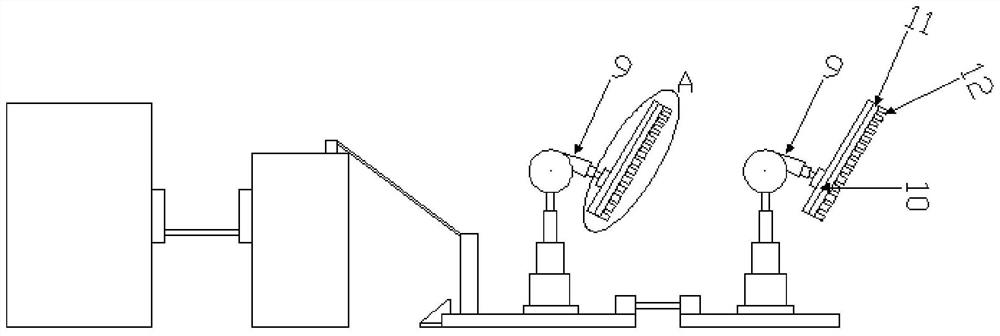

[0045] see figure 1 , figure 2 , the main component thermoelectric power generation unit 1 is connected with the mechanical telescopic connecting rod 5 to form. Simultaneously, this device adopts double generating units to work simultaneously, and its main body is connected on the fixing device 2 and connected by the first wire 6 to generate association. The fixing device 2 is connected to the storage battery 4 through the second wire 7 and the third wire 8 , and is finally connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com