Processing method of fermented recombinant fish product and product thereof

A processing method and technology for fish meat products, which are applied in the directions of yeast-containing food ingredients, bacteria and lactobacilli used in food preparation, etc., can solve problems such as inconvenience of eating, and achieve the effects of convenient eating, promoting flavor substances, and shortening fermentation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

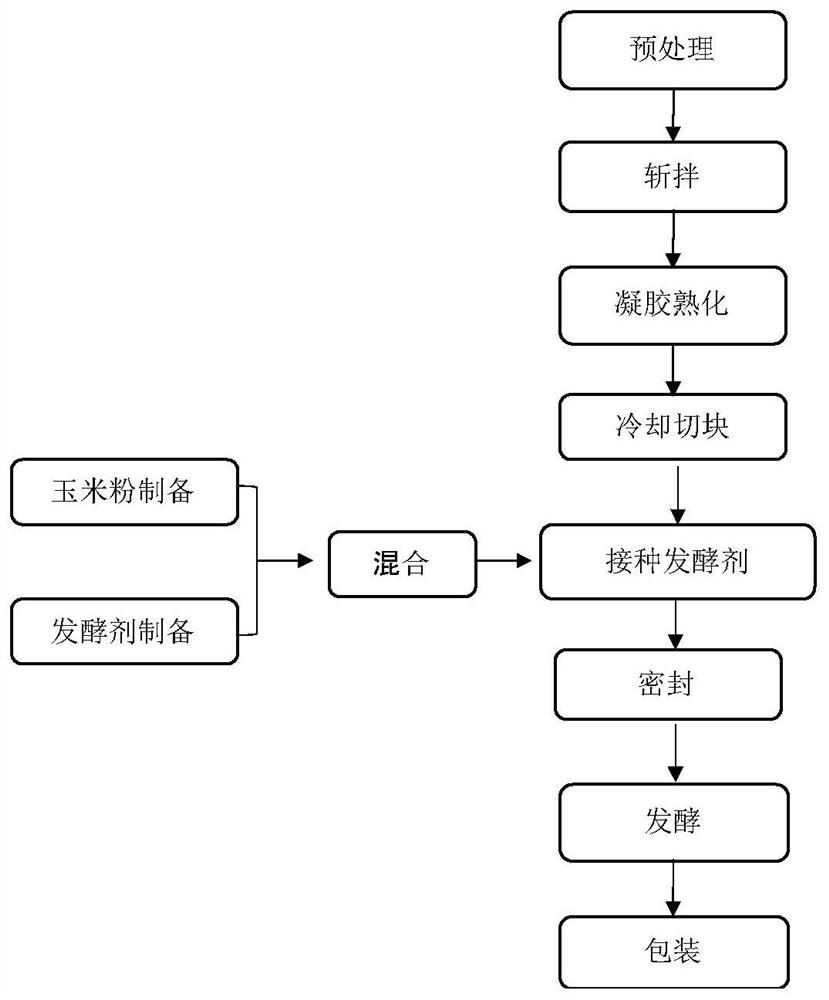

Method used

Image

Examples

Embodiment 1

[0035] (1) Thawing: Thaw frozen surimi at 4°C for 12 hours.

[0036](2) Chop and mix: use a chopping machine to chop and mix the thawed surimi for 2 minutes to obtain minced fish, add 1.5% salt and 10% ice water and then continue chopping and mixing for 4 minutes, then stir in a vacuum mixer for 3 minutes, The air mixed in the surimi is extracted, and the whole process is operated in an environment below 15°C.

[0037] (3) Gel curing: transfer the minced surimi to a mold by hand or mechanically, and then use a two-stage heating method for gel curing, first heating at 40°C for 30 minutes, and then cooking at 100°C 30min.

[0038] (4) Cooling and cutting into pieces: the surimi gel after cooking and forming is rapidly cooled to below 40°C with cold water or cold wind, and then cut into cubes of about 3cm*2cm*2cm.

[0039] (5) Starter preparation: The starter is made up of commercial starter Lactobacillus plantarum powder, aromatic yeast powder and corn flour, and takes 0.02% s...

Embodiment 2

[0045] (1) Thawing: Thaw frozen surimi at 4°C for 12 hours.

[0046] (2) Chop and mix: use a chopping machine to chop and mix the thawed surimi for 2 minutes to obtain minced fish, add 1.5% salt and 10% ice water and then continue chopping and mixing for 4 minutes, then stir in a vacuum mixer for 3 minutes, The air mixed in the surimi is extracted, and the whole process is operated in an environment below 15°C.

[0047] (3) Gel curing: transfer the minced surimi to a mold by hand or mechanically, and then use a two-stage heating method for gel curing, first heating at 40°C for 30 minutes, and then cooking at 100°C 30min.

[0048] (4) Cooling and cutting into pieces: the surimi gel after cooking and forming is rapidly cooled to below 40°C with cold water or cold wind, and then cut into cubes of about 3cm*2cm*2cm.

[0049] (5) Preparation of leavening agent: leavening agent is made up of commercial starter Lactobacillus plantarum powder and corn flour, gets the Lactobacillus p...

Embodiment 3

[0055] (1) Thawing: Thaw frozen surimi at 4°C for 12 hours.

[0056] (2) Chop and mix: use a chopping machine to chop and mix the thawed surimi for 2 minutes to obtain minced fish, add 1.5% salt and 10% ice water and then continue chopping and mixing for 4 minutes, then stir in a vacuum mixer for 3 minutes, The air mixed in the surimi is extracted, and the whole process is operated in an environment below 15°C.

[0057] (3) Gel curing: transfer the minced surimi to a mold by hand or mechanically, and then use a two-stage heating method for gel curing, first heating at 40°C for 30 minutes, and then cooking at 100°C 30min.

[0058] (4) Cooling and cutting into pieces: the surimi gel after cooking and forming is rapidly cooled to below 40°C with cold water or cold wind, and then cut into cubes of about 3cm*2cm*2cm.

[0059] (5) Preparation of starter: starter is made up of commercial starter aroma yeast bacterium powder and corn flour, starter is made up of commercial starter a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com