Stuffing for making rice dumplings, preparation method of stuffing and rice dumplings

A technology for stuffing and raw materials, which is applied in the field of stuffing and preparation for making glutinous rice balls, which can solve the problems of affecting the taste of glutinous rice balls, short storage time in refrigeration, and poor taste of glutinous rice balls, so as to inhibit the growth of bacteria and reduce the cracking of glutinous rice balls , Increase the effect of aroma and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation Examples of Raw Materials and Intermediates

[0043] The sources of raw materials used in this application are as follows:

[0044] Table 1 source of raw materials

[0045] raw material name source solid lard Hebei Dahongmen Jinsheng Oil black sesame powder Dongxing Sihaitong Agricultural Trade Co., Ltd. white sesame powder Dongxing Sihaitong Agricultural Trade Co., Ltd. powdered sugar Guangxi Fengtang Rongshuihehe Sugar Industry Improver YL3081--Yanlin Biology frozen oil Palm Oil Yihaijiali

[0046] All raw materials except osmanthus sauce and the raw materials listed in the above table are commercially available, and there is no special requirement.

[0047] The osmanthus sauce is made from the following raw materials in parts by weight: 10Kg of dried osmanthus, 10Kg of maltose, 20Kg of malt syrup, 5Kg of white sugar powder, and 2Kg of white wine.

[0048] The preparation steps of sweet-scented osm...

Embodiment

[0056] The filling is prepared as follows:

[0057] S1: Put black sesame powder, white sesame powder, white sugar powder and edible salt into the blender and mix;

[0058] S2: put the orange cake into a pulverizer for pulverization, and then put it into a mixer together with the sweet-scented osmanthus sauce prepared in the preparation example for mixing to obtain a mixture A;

[0059] S3: Finally, the mixture A obtained by mixing S2 is evenly divided into three parts, and added into solid lard three times for mixing and stirring, and the stirring time is 1-2 min each time, and finally mixed and stirred evenly.

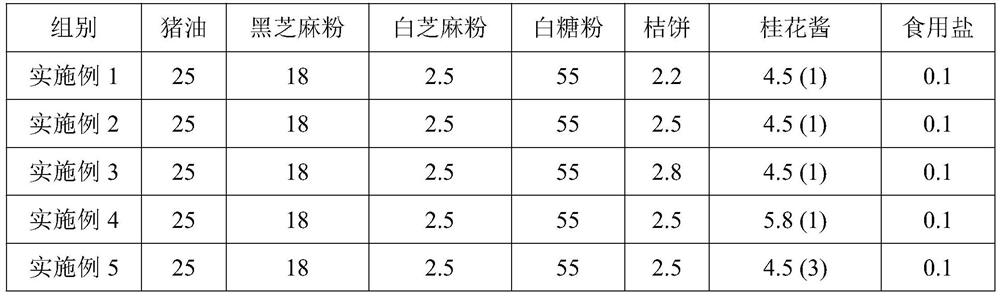

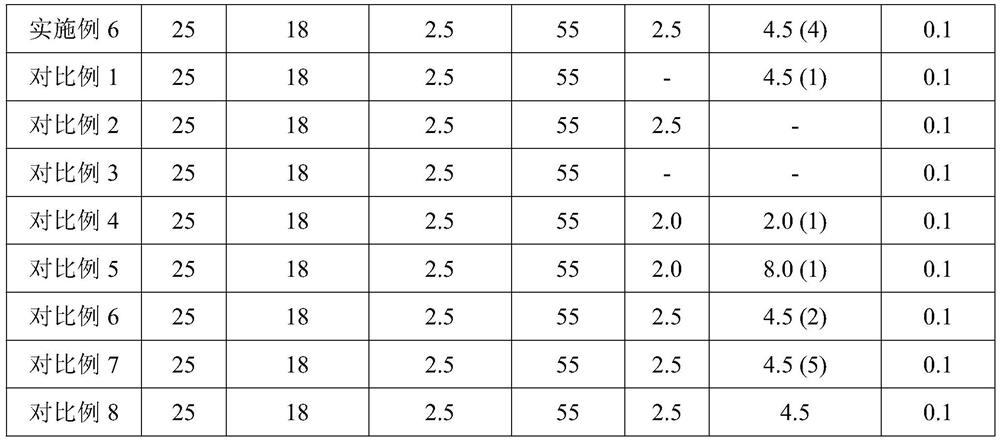

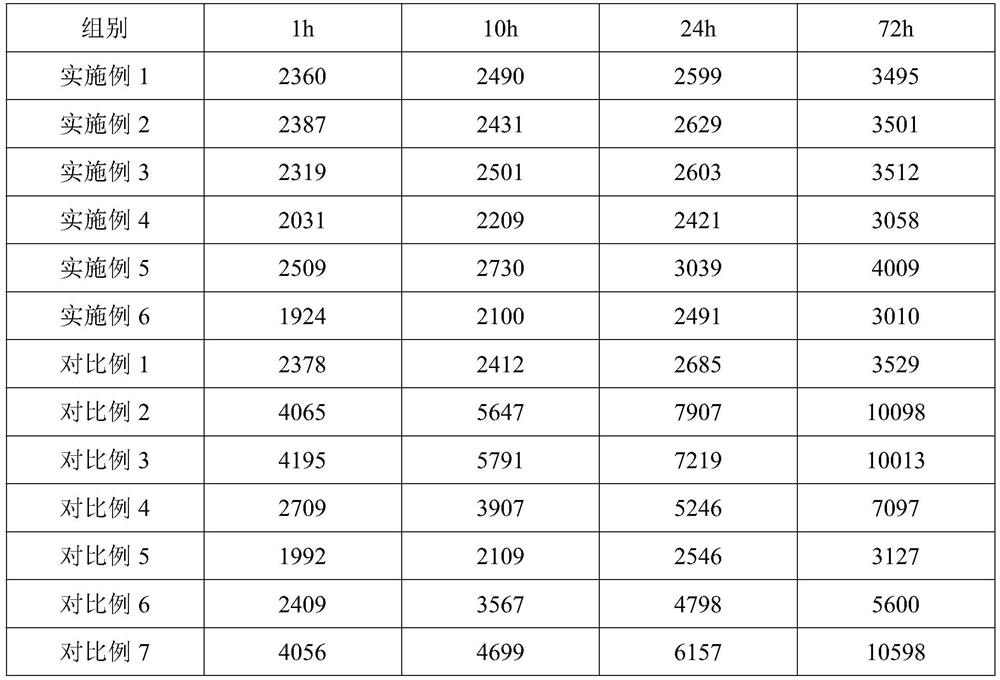

[0060] Raw material and content table (unit: Kg) in the embodiment of table 3 and comparative example filling

[0061]

[0062]

[0063] *4.5(1) in the column of osmanthus sauce in the above table means: the sweet-scented osmanthus sauce prepared by preparation (1), and the added weight of osmanthus sauce is 4.5Kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com