Method for treating carbon disulfide in viscose fiber production waste gas

A viscose fiber, carbon disulfide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

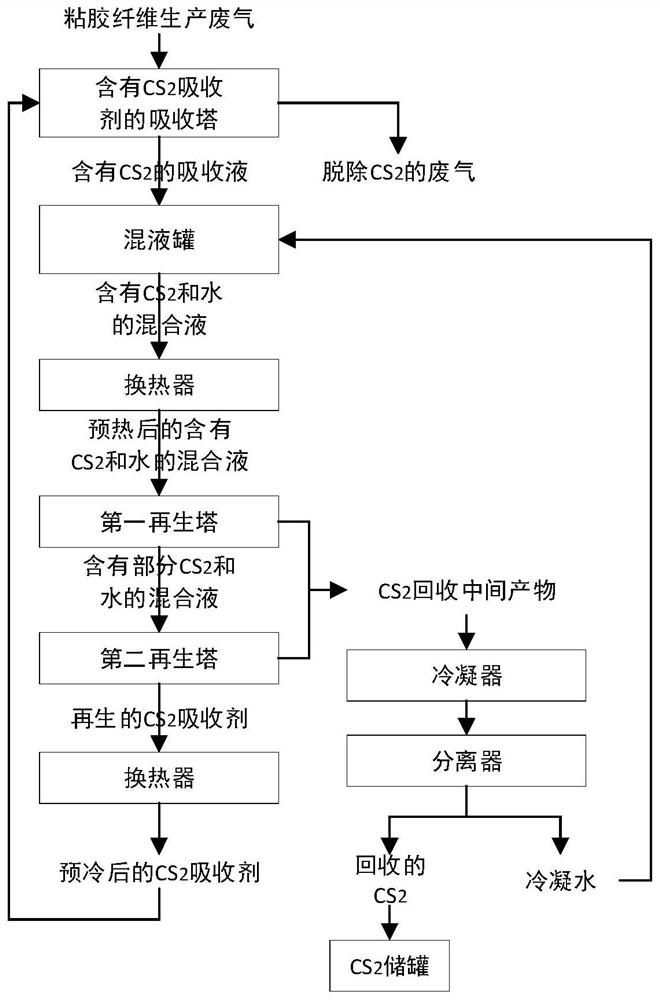

Method used

Image

Examples

Embodiment 1

[0051] The temperature is 30℃, CS 2 The content is 8225mg / m 3 The raw material gas is continuously sent to the absorption tower, and the CS in the raw material gas in the absorption tower 2 CS sprayed from the upper part of the absorption tower 2 Absorbent HO(CH 2 CH 2 O) 3 CH 2 CH 2 CH 2 CH 3 Absorption, absorption temperature is 30℃, CS 2 The liquid-gas ratio of absorbent and feed gas entering the absorption tower is 6L / m 3 , remove CS 2 The purified gas is sent to the exhaust flue for other treatment; absorb CS 2 The final absorption liquid enters the mixing tank from the bottom of the absorption tower through the pump to be mixed with water, and contains CS after mixing. 2 The mass percentage of water in the mixture with water is 20%; it contains CS 2 The mixed liquid (rich liquid) with water is pumped into the lean-rich liquid heat exchanger from the mixed liquid tank, and after absorbing heat, it enters the first regeneration tower with a bottom temperature ...

Embodiment 2

[0053] Others are the same as in Example 1, the difference is CS 2 The absorbent is HO (CH 2 CH 2 O) 6 CH 3 . CS in purified gas 2 The content is 319mg / m 3 , CS in the feed gas 2 The removal rate was 96.1%.

Embodiment 3

[0055] Others are the same as in Example 1, the difference is CS 2 The absorbent is HO (CH 2 CH 2 O) 4 H. CS in purified gas 2 The content is 576mg / m 3 , CS in the feed gas 2 The removal rate was 93.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com