Method for treating hydrogen sulfide in viscose fiber production waste gas

A viscose fiber and hydrogen sulfide technology, applied in the textile field, can solve the problems of high cost of low-concentration waste gas treatment, unattainable corporate governance, odor, and high operation cost, and achieve sustainable long-term development, high safety, and reduced operation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

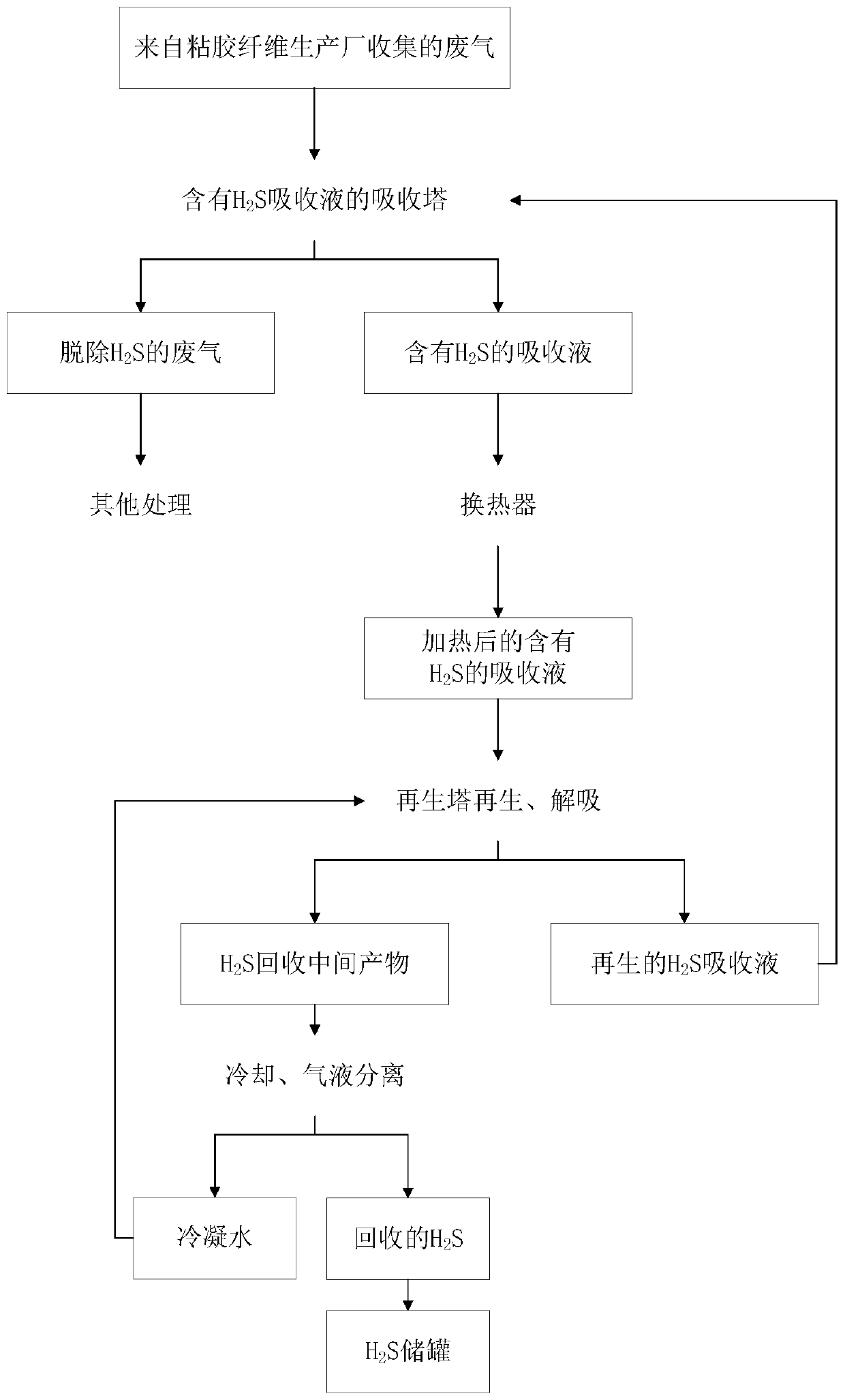

Image

Examples

Embodiment 1

[0042] The temperature is 20°C, H 2 S content is 4675mg / m 3 The raw material gas is continuously sent to the absorption tower, and the H in the raw gas in the absorption tower2 S is sprayed by H from the upper part of the absorption tower 2 S absorption liquid absorption, the absorption liquid contains 1.5mol / L ionic liquid [(CH 3 -)(CH 3 CH 2 CH 2 CH 2 -)N-CH 2 CH 2 CH 2 -NH 2 + -CH 2 CH 3 ]CH 3 COO - , the absorption temperature is 30°C, the removal of H 2 The purified gas after S is sent to the exhaust flue for other treatment; absorb H 2 The absorption liquid (rich liquid) after S enters the lean-rich liquid heat exchanger through the pump from the bottom of the absorption tower, and after absorbing heat, it enters the regeneration tower from the upper part of the regeneration tower for regeneration and desorption of H 2 S, desorption temperature is 85°C, desorption H 2 The absorption liquid (lean liquid) after S flows out from the bottom of the regenerati...

Embodiment 2

[0044] Others are the same as in Example 1, and the difference is that the ionic liquid in the absorption liquid is [(CH 3 -)(CH 3 CH 2 CH 2 CH 2 -)N-CH 2 CH 2 CH 2 -NH 2 + -CH 2 CH 3 ]PF 6 - . H in purified gas 2 S content is 96mg / m 3 , H in raw gas 2 The removal rate of S was 97.9%.

Embodiment 3

[0046] Others are the same as in Example 1, and the difference is that the ionic liquid in the absorption liquid is [(CH 3 -)(CH 3 CH 2 CH 2 CH 2 -)N-CH 2 CH 2 CH 2 -NH 2 + -CH 2 CH 3 ] BF 4 - . H in purified gas 2 S content is 89mg / m 3 , H in raw gas 2 The removal rate of S was 98.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com