Anti-corrosion and damp-proof method for furniture and damp-proof furniture

A technology for furniture and moisture-proof paint, applied in the field of furniture, can solve problems such as unsightly appearance, cracking of the paint surface of wooden furniture, affecting the aesthetics and practicability of wooden furniture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for anticorrosion and moisture-proofing of furniture, comprising the following steps:

[0040] (1) Once dried, the wood for preparing furniture is placed in a drying room for drying;

[0041] (2) secondary drying, the wood in step 1 is placed under the high-frequency electromagnetic wave environment and carries out secondary drying;

[0042] (3) putting the wood in step 2 into a grinder for grinding, and polishing the wood;

[0043] (4) Spray the moisture-proof paint on the wood in step 3 with a spraying device, then spray the colored topcoat, and carry out ultraviolet curing, repeat at least three times, and the moisture-proof paint layer reaches at least three layers, and obtain the anti-corrosion and moisture-proof furniture board;

[0044] Wherein, the moisture-proof paint is composed of perchlorethylene resin, epichlorohydrin, butyl acetate, acetone, and toluene;

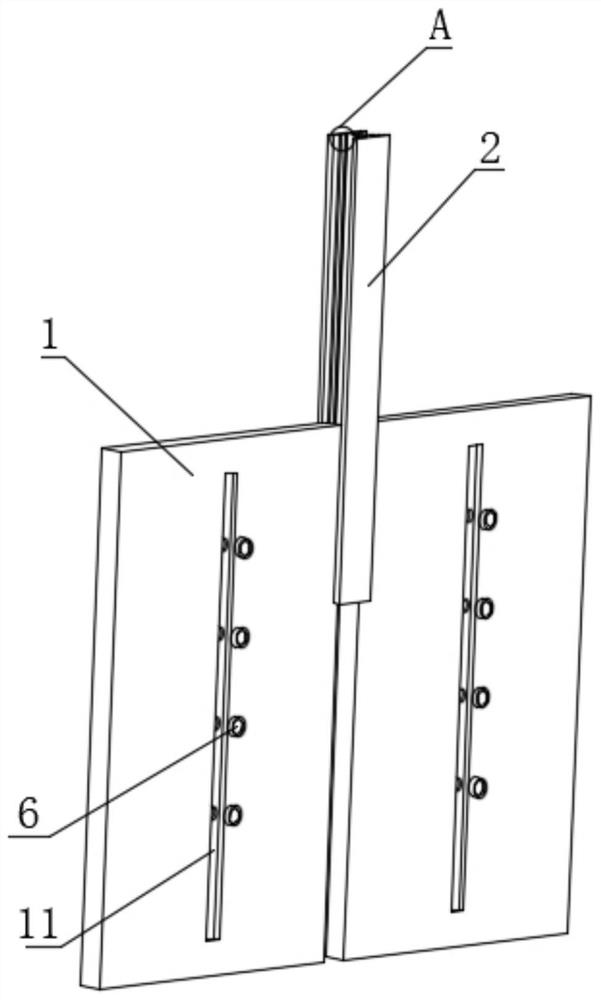

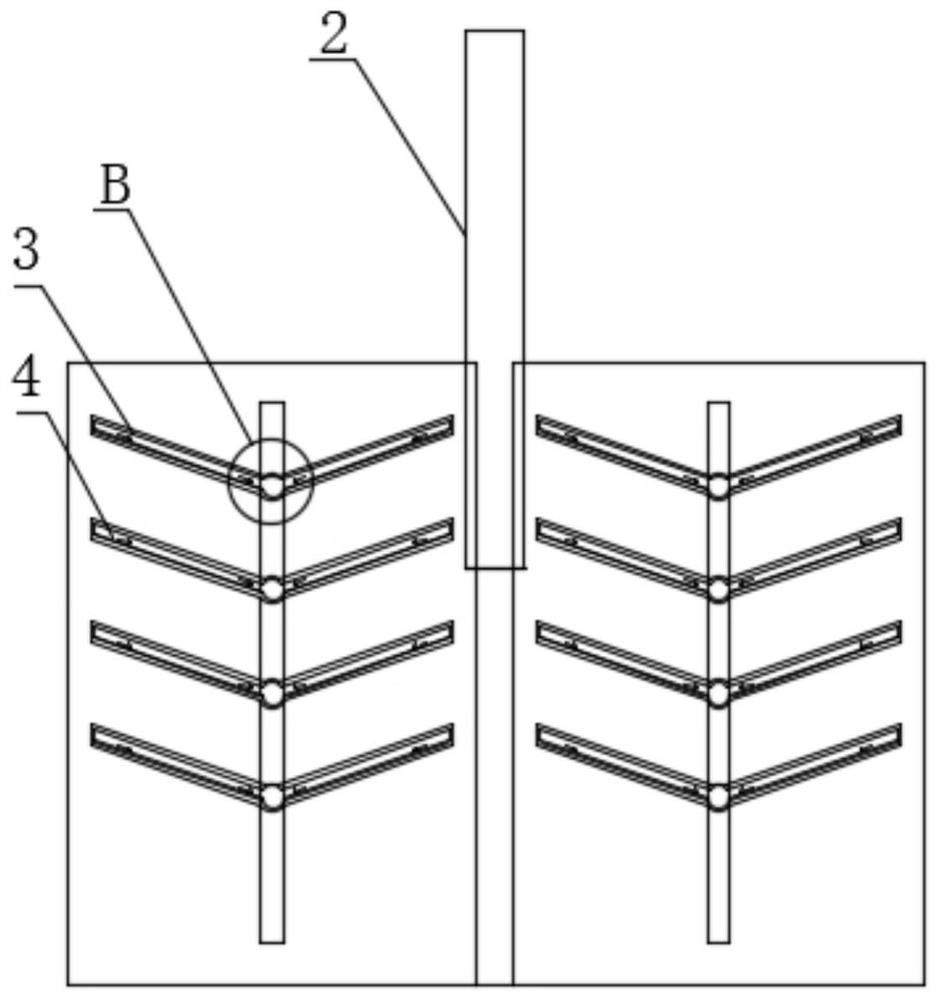

[0045] (5) Assembling and splicing the boards in step 4 according to the furniture manufac...

Embodiment 2

[0058] see Figure 7 In this embodiment, different from Embodiment 1, the top of the mixing bin 14 is fixedly connected with an electric telescopic rod 25, the top of the electric telescopic rod 25 is fixedly connected with a top plate 26, and the middle bottom of the top plate 26 is fixedly connected with a second clamping mechanism. , the second clamping mechanism has the same structure as the first clamping mechanism, and the height of the top plate 26 can be easily controlled through the electric telescopic rod 25, so that the second clamping mechanism on the top plate 26 can clamp and abut the top of the furniture board , to improve the stability of furniture panels during transportation.

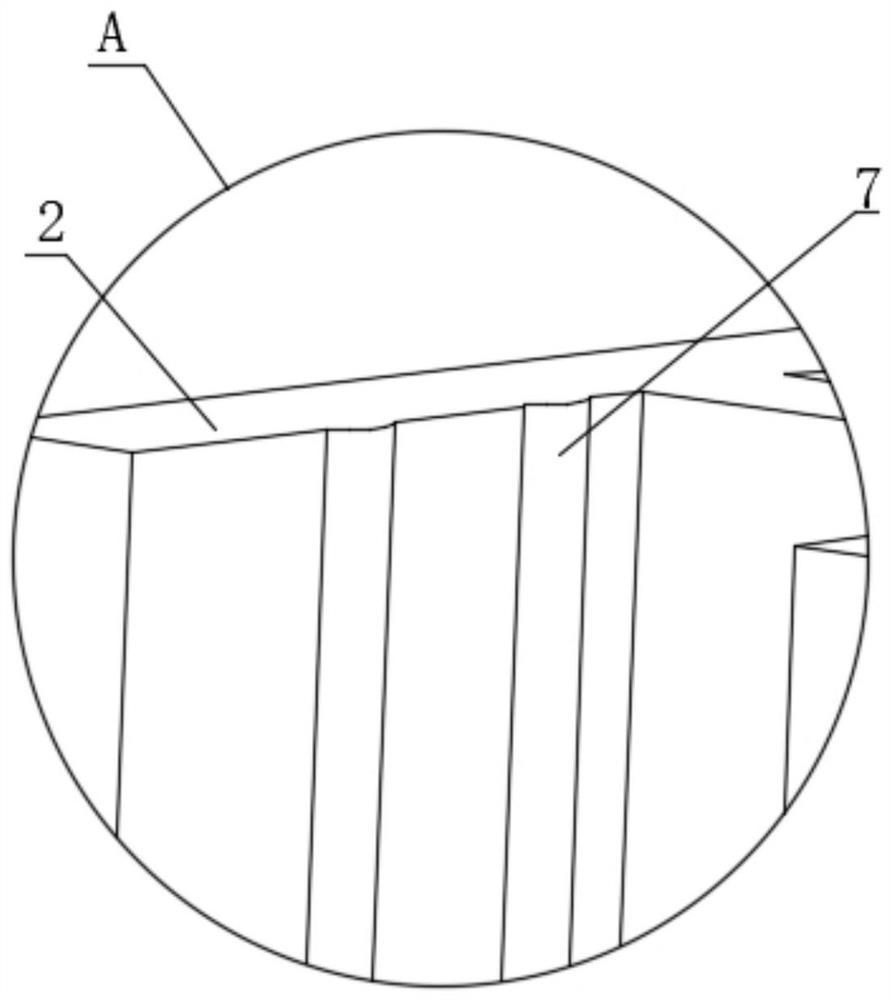

[0059] When the spraying device proposed by the present invention is working, the furniture board is fixed on the conveying mechanism through the first clamping mechanism, and then the drive motor 15 is started to drive the furniture board to move. When the furniture board is moving, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com