Full-automatic selective wave soldering device

A wave soldering and selective technology, applied in the direction of tin feeding device, auxiliary device, welding equipment, etc., can solve the problems of complicated installation, high mechanical loss, and bulky

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

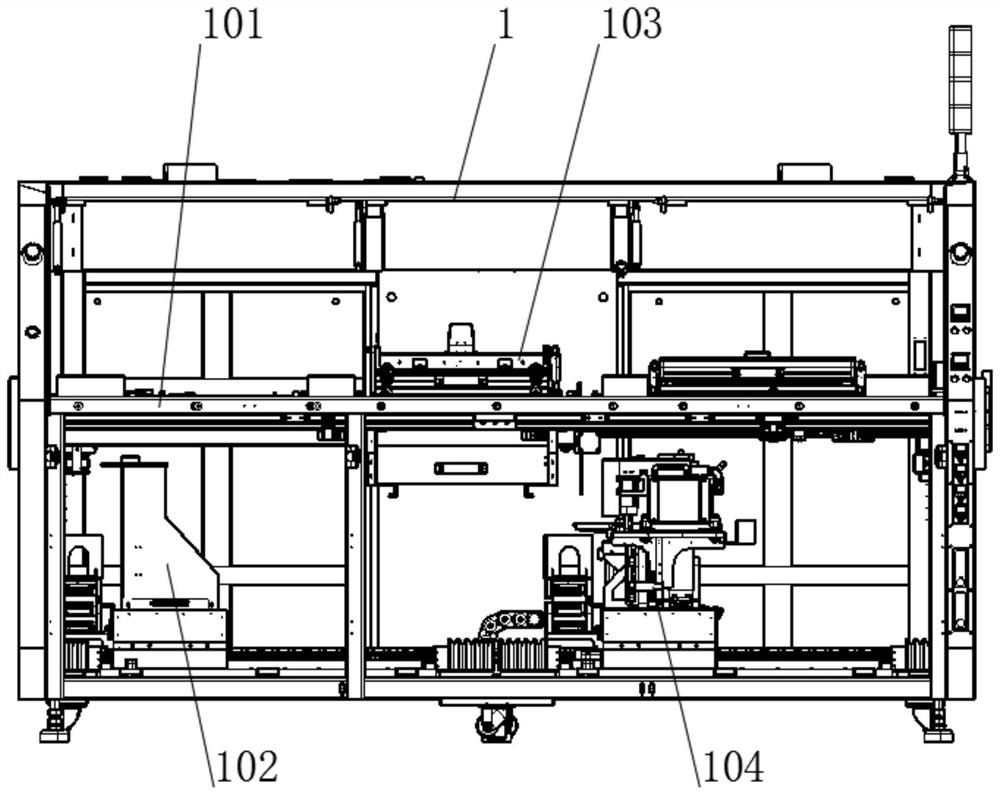

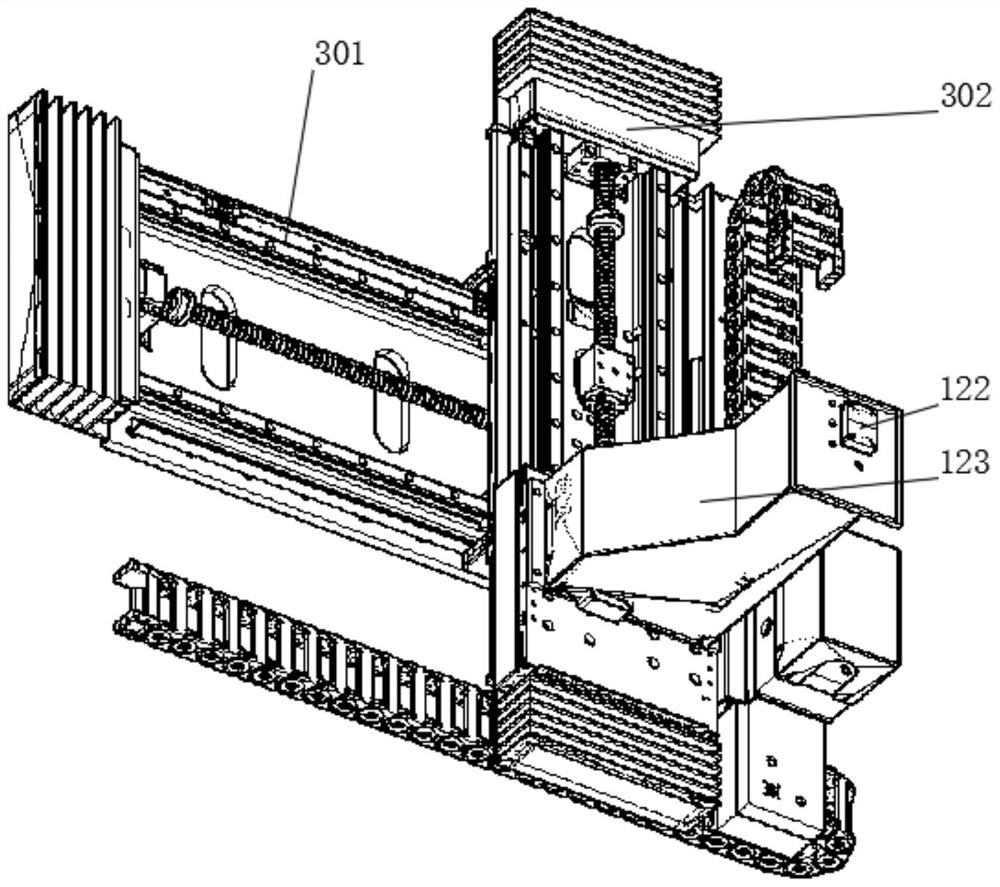

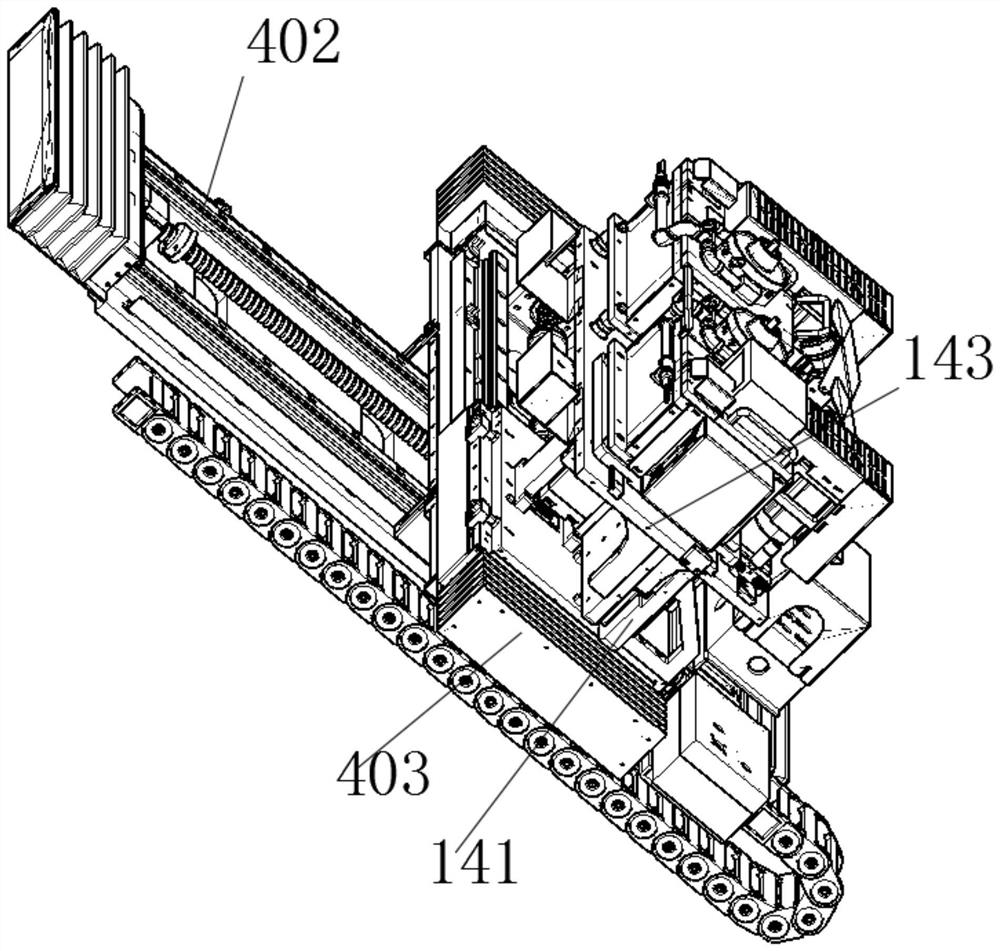

[0037] see Figure 1 to Figure 10 , the present invention provides a technical solution: a fully automatic selective wave soldering device, including a main body 1 and a transport rail 101 arranged inside the main body 1, a flux spraying mechanism 102, a double-layer preheating mechanism 103 and a selective soldering mechanism 104. The transportation guide rail 101 includes a board-in guide rail and a board-out guide rail. Multiple single-axis width adjustment components 9 are arranged on the board-in guide rail. The precision spray valve 122, the driven guide rail 302 is set on the active guide rail 301, the movable platen 123 is installed on the driven guide rail 302, and the high-precision spray valve 122 is set on the top of the movable platen 123, the double-layer preheating mechanism 103 includes The upper preheating module and the lower preheating module, the upper preheating module includes the shell 8, the heat pipe 6 and the rectifying copper pipe 7, the selective we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com