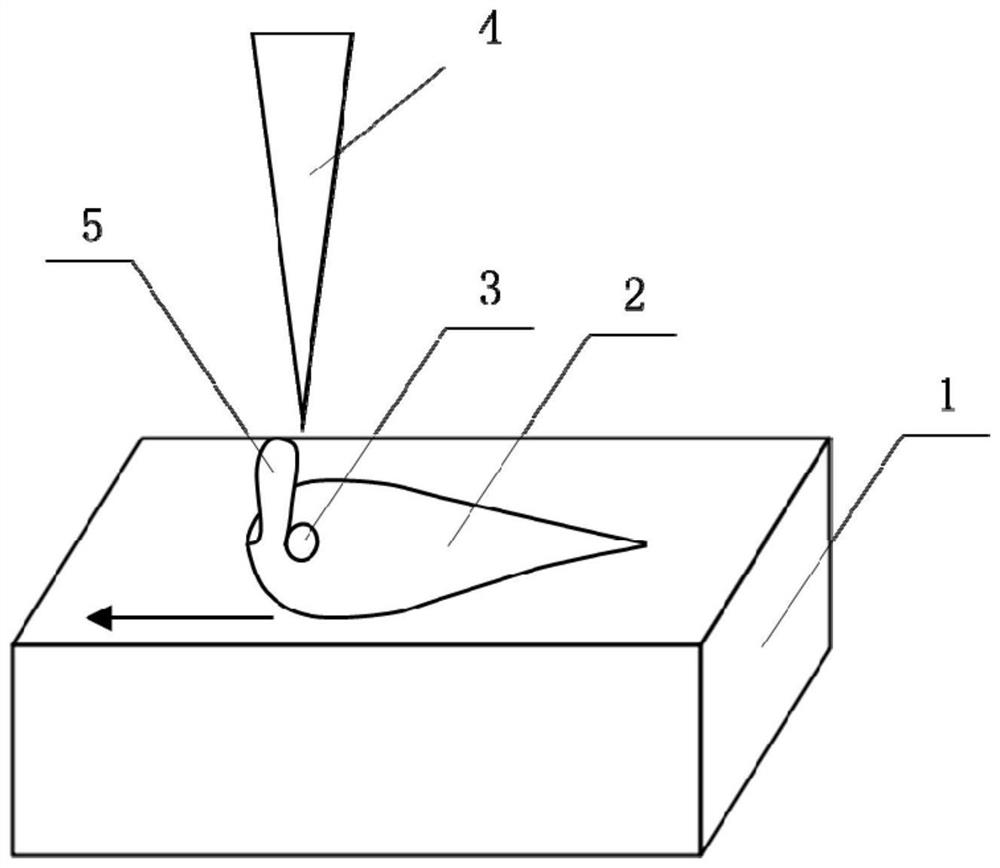

Myriawatt-level laser double-beam welding method for inhibiting welding liquid column and splashing

A welding method and double-beam technology, applied in welding equipment, laser welding equipment, manufacturing tools, etc., can solve problems such as welding spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Carry out surfacing welding of Q235 low carbon steel plate, specifically:

[0029] The test base material is Q235 low carbon steel, and the test plate size is 300×300×30mm. The laser used is a YLS-30000 fiber laser, pure argon is used as the shielding gas, and the shielding gas flow rate is 25L / min.

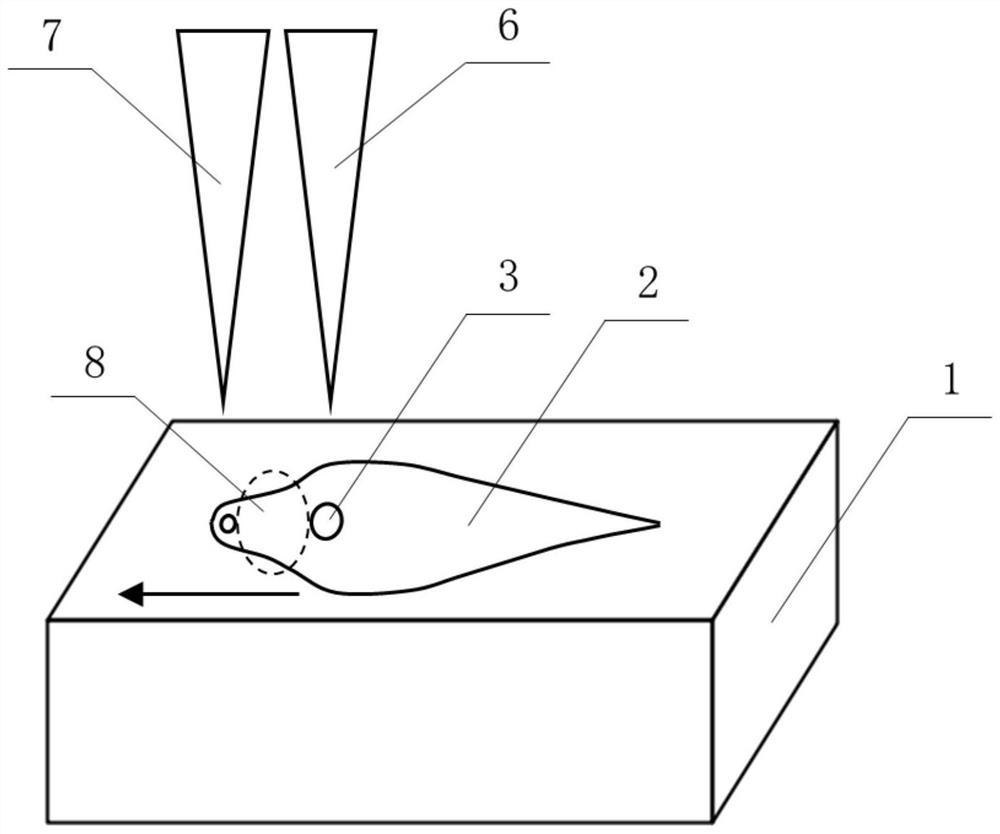

[0030] Double-beam laser welding parameters in the implementation process: two laser beams are obtained after one beam of laser beam is split by an optical lens, such as figure 2 As shown, the front beam laser P 1 The power is 3000W, the rear beam laser P 2 The power of the laser is 20000W, the distance between the two laser beams is 5mm, and the welding speed is 1m / min.

Embodiment 2

[0035] Carry out surfacing welding of stainless steel flat plate, specifically:

[0036] The test base material is 316 stainless steel, and the size of the test plate is 300×300×30mm. The laser used is a YLS-30000 fiber laser, pure argon is used as the shielding gas, and the shielding gas flow rate is 25L / min.

[0037] The parameters of the double-beam laser welding during the implementation process: the front beam laser is an oscillating laser, the oscillating amplitude is 3mm, the oscillating frequency is 100Hz, the power is 3000W, the rear beam laser power is 20000W, the distance between the two laser beams is 10mm, and the welding speed is 1m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com