Steel slag activity exciting agent, active steel slag powder comprising same and application of active steel slag powder

A technology of active activator and steel slag powder, which is applied in the field of building materials, can solve the problems of low active material content, low activity, and low utilization rate, and achieve the effects of increased activity of steel slag, catalytic activator, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

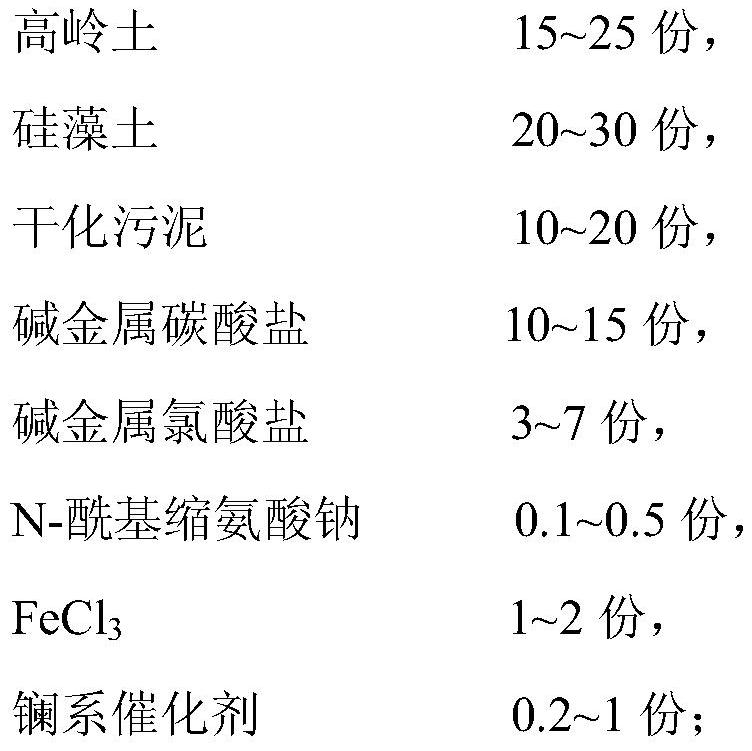

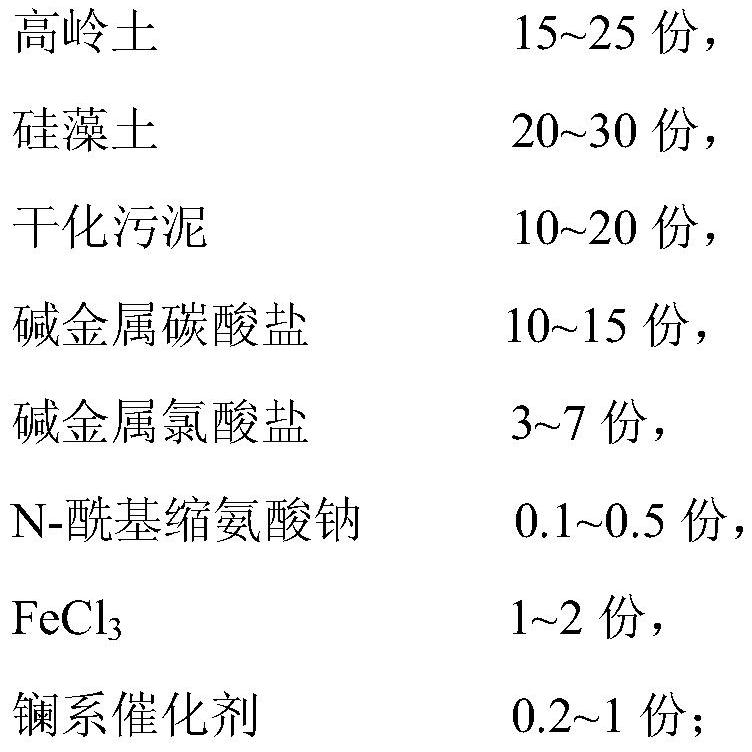

[0025] A steel slag active activator, the activator is composed of the following materials mixed uniformly in parts by mass: 15 parts of kaolin, 30 parts of diatomaceous earth, 10 parts of dried sludge, 15 parts of Na 2 CO 3 , 3 parts KClO 3 , 0.5 part sodium N-acyl peptide, 1 part FeCl 3 , 1 part of lanthanide catalyst;

[0026] Mix the above-mentioned components evenly and grind them, the specific surface area is 200m 2 / kg, to obtain steel slag active stimulator;

[0027] Described lanthanide catalyst is lanthanum nitrate;

[0028] The dried sludge is dried sludge particles with a water content of 5%.

[0029] Spray 8% activator into the liquid steel slag discharged from the boiler, mix evenly, then lower the temperature and grind to obtain active steel slag powder; the specific surface area of the ground active steel slag powder is 400m 2 / kg.

Embodiment 2

[0031] A steel slag active activator, the activator is composed of the following substances mixed uniformly in parts by mass: 25 parts of kaolin, 20 parts of diatomite, 20 parts of dried sludge, 10 parts of K 2 CO 3 , 7 parts NaClO 3 , 0.1 part sodium N-acyl peptide, 2 parts FeCl 3 , 0.2 part of lanthanide catalyst;

[0032] Mix the components evenly and grind them, the specific surface area is 400m 2 / kg, to obtain steel slag active stimulator;

[0033] Described lanthanide catalyst is lanthanum sulfate;

[0034] The dried sludge is absolutely dry sludge particles with a moisture content of 0%.

[0035] Spray 10% activator into the liquid steel slag discharged from the boiler, mix evenly, then lower the temperature and grind to obtain active steel slag powder; the specific surface area of the ground active steel slag powder is 440m 2 / kg.

Embodiment 3

[0037] A steel slag active activator, the activator is composed of the following materials mixed uniformly in parts by mass: 20 parts of kaolin, 25 parts of diatomaceous earth, 15 parts of dried sludge, 12 parts of Na 2 CO 3 , 5 parts KClO 3 , 0.3 parts of sodium N-acyl peptides, 1.5 parts of FeCl 3 , 0.6 part of lanthanide catalyst;

[0038] Mix the components evenly and grind them, the specific surface area is 325m 2 / kg, to obtain steel slag active stimulator;

[0039] The lanthanide catalyst is that the mass ratio of lanthanum nitrate to lanthanum sulfate is 1:1;

[0040] The dried sludge is dried sludge powder with a water content of 0.4%.

[0041] Spray 12% activator into the liquid steel slag discharged from the boiler, mix evenly, then cool down and grind to obtain active steel slag powder; the specific surface area of the ground active steel slag powder is 550m 2 / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com