Damage color development type epoxy glass polymer and fiber or explosive composite material thereof

An epoxy and polymer technology, applied in the direction of explosives, a single substance as an explosive, non-explosive/non-thermal agent components, etc., can solve the problem of damage and color development of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The damage color-developing epoxy glass macromolecule of the present invention is composed of 50-70 parts of epoxy resin A, 10-30 parts of epoxy curing agent B, and 5-20 parts of epoxy diluent in parts by weight.

[0028] The epoxy resin A is diphenyl dithiodiglycidyl ether, the epoxy curing agent B is tetraethylenepentamine, and the epoxy diluent is phenyl monoglycidyl ether.

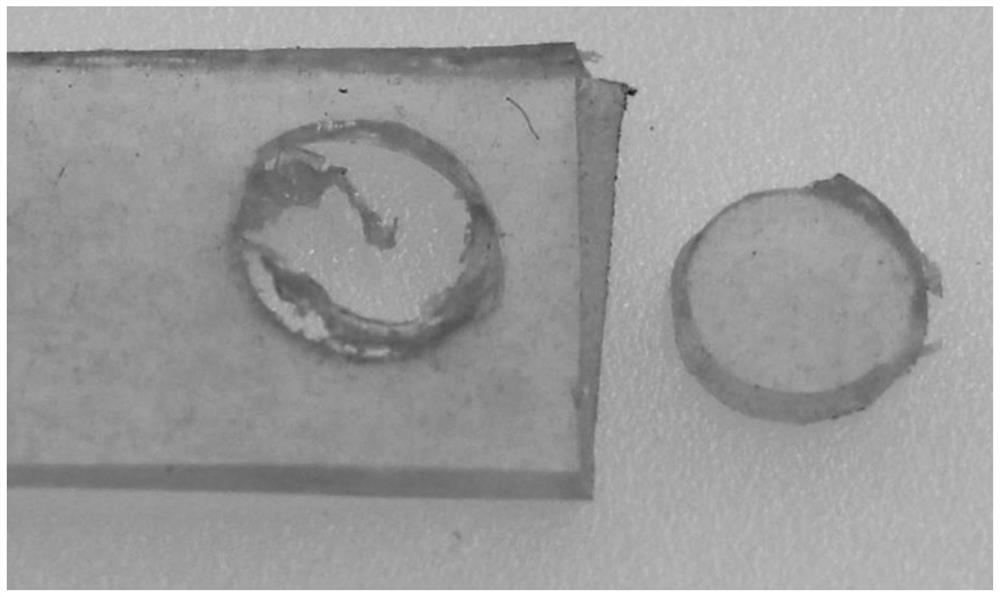

[0029] The damage-coloring epoxy glass polymer exhibits a color change (pink) visible to the naked eye when damaged, such as figure 1 shown

Embodiment 2

[0031] The damaged color-developing epoxy glass polymer of the present invention comprises 70-100 parts of epoxy resin A, 30-50 parts of epoxy curing agent B, 20-40 parts of epoxy diluent and 20-50 parts by weight. Components of inorganic fillers.

[0032] The epoxy resin A is diphenyl dithiodiglycidyl ester, the epoxy curing agent B is m-phenylenediamine, the epoxy diluent is phenyl monoglycidyl ester, and the inorganic filler 10-30nm SiO 2 and other inorganic particles.

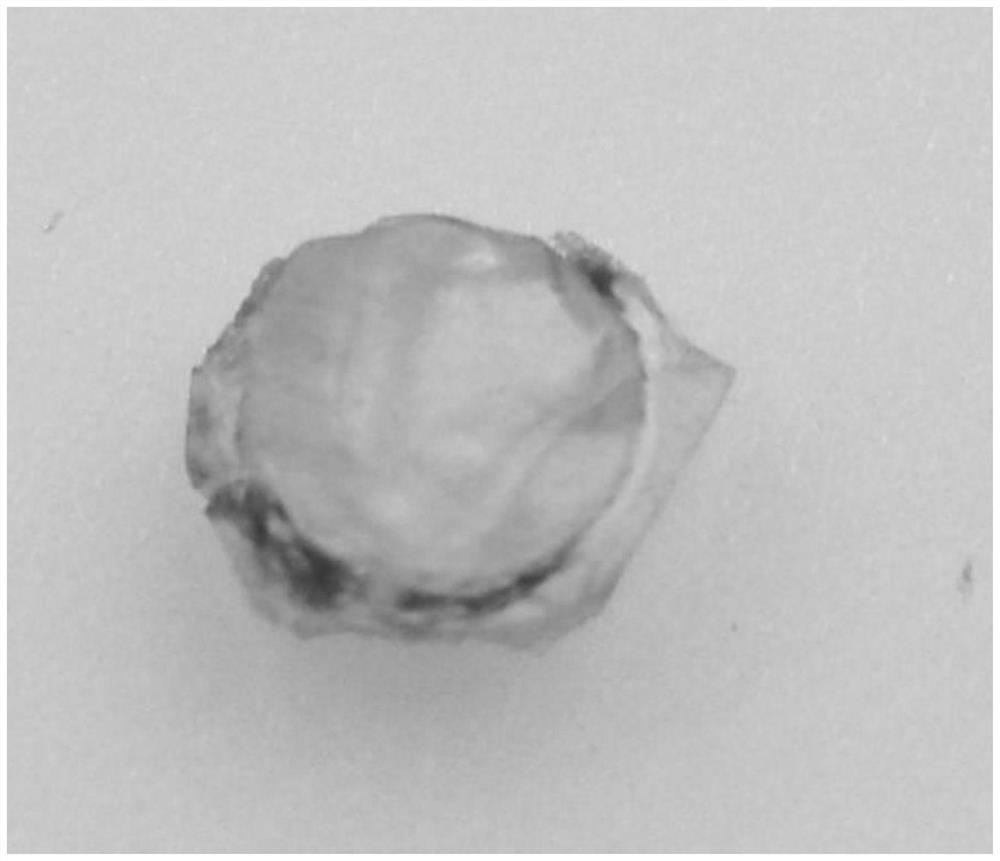

[0033] The damage-coloring epoxy glass polymer exhibits a color change (orange) visible to the naked eye when damaged, such as figure 2 shown

Embodiment 3

[0035] The damage color-developing epoxy glass polymer of the present invention comprises 30-60 parts of epoxy resin A, 15-35 parts of epoxy curing agent B, 10-20 parts of epoxy diluent and 10-20 parts by weight. Components of inorganic fillers.

[0036] The epoxy resin A is diphenyl dithiodiglycidyl ester, the epoxy curing agent B is methyl hexahydrophthalic anhydride, and the epoxy diluent is bisphenol F diglycidyl Ether, the inorganic filler is SiO of 100-200nm 2 and other inorganic particles.

[0037] The damage-coloring epoxy glass polymer exhibits a color change visible to the naked eye when damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com