A kind of nanomaterial, preparation method and application thereof

A technology of nanomaterials and polymerization reaction, which is applied in the field of viscosity reduction of heavy oil, can solve the problems of surfactant migration loss, poor control of manufacturing cracks, and difficulty in finding gas sources, etc., to achieve reduced adsorption, good nano-gain effect, and improved The effect of interface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1 Preparation of Nanomaterial 1#

[0055] 1. Weigh 15g of monomer AOS (sodium α-olefin sulfonate) and 15g of monomer acrylamide, 20g of monomer maleic anhydride organic hydrophilic monomer, 10g of coupled montmorillonite into a three-necked flask, add 900g deionized water, stir to dissolve, pass nitrogen for 30min, and remove the oxygen in the solution;

[0056] 2. Weigh the initiator potassium persulfate of 0.25g, add 50g deionized water, stir and dissolve, pass nitrogen for 30min, and remove the oxygen in the solution (initiator concentration 0.5wt%);

[0057] 3. Mechanically stir the solution in 1 at 250rpm, start heating, and set the heating temperature to 55°C;

[0058] 4. When the temperature of the solution in the flask reaches 45°C, add potassium persulfate in 2 dropwise with a constant pressure funnel, while setting the reaction temperature to 80°C, drop the initiator in 7-10min, and wait for the temperature of the reaction solution to reach 80°C. Timin...

Embodiment 2

[0059] Example 2 Preparation of Nanomaterial 2#

[0060] 1. Weigh 15g monomer AOS (α-alkene sulfonate sodium) and 15g monomer acrylamide, 20g monomer maleic anhydride organic hydrophilic monomer, 20g coupled montmorillonite into there-necked flask, add 900g deionized water, stir to dissolve, pass nitrogen for 30min, and remove the oxygen in the solution;

[0061] 2. Weigh the initiator potassium persulfate of 0.25g, add 50g deionized water, stir and dissolve, pass nitrogen for 30min, and remove the oxygen in the solution (initiator concentration 0.5wt%);

[0062] 3. Mechanically stir the solution in 1 at 250rpm, start heating, and set the heating temperature to 55°C;

[0063] 4. When the temperature of the solution in the flask reaches 45°C, add potassium persulfate in 2 dropwise with a constant pressure funnel, while setting the reaction temperature to 80°C, drop the initiator in 7-10min, and wait for the temperature of the reaction solution to reach 80°C. Timing, the react...

Embodiment 3

[0064] Example 3 Preparation of Nanomaterial 3#

[0065] 1. Weigh 15g of monomer AOS (sodium α-olefin sulfonate) and 15g of monomer acrylamide, 20g of monomer maleic anhydride organic hydrophilic monomer, 30g of coupled montmorillonite into there-necked flask, add 900g deionized water, stir to dissolve, pass nitrogen for 30min, and remove the oxygen in the solution;

[0066] 2. Weigh the initiator potassium persulfate of 0.25g, add 50g deionized water, stir and dissolve, pass nitrogen for 30min, and remove the oxygen in the solution (initiator concentration 0.5wt%);

[0067] 3. Mechanically stir the solution in 1 at 250rpm, start heating, and set the heating temperature to 55°C;

[0068] 4. When the temperature of the solution in the flask reaches 45°C, add potassium persulfate in 2 dropwise with a constant pressure funnel, while setting the reaction temperature to 80°C, drop the initiator in 7-10min, and wait for the temperature of the reaction solution to reach 80°C. Timin...

PUM

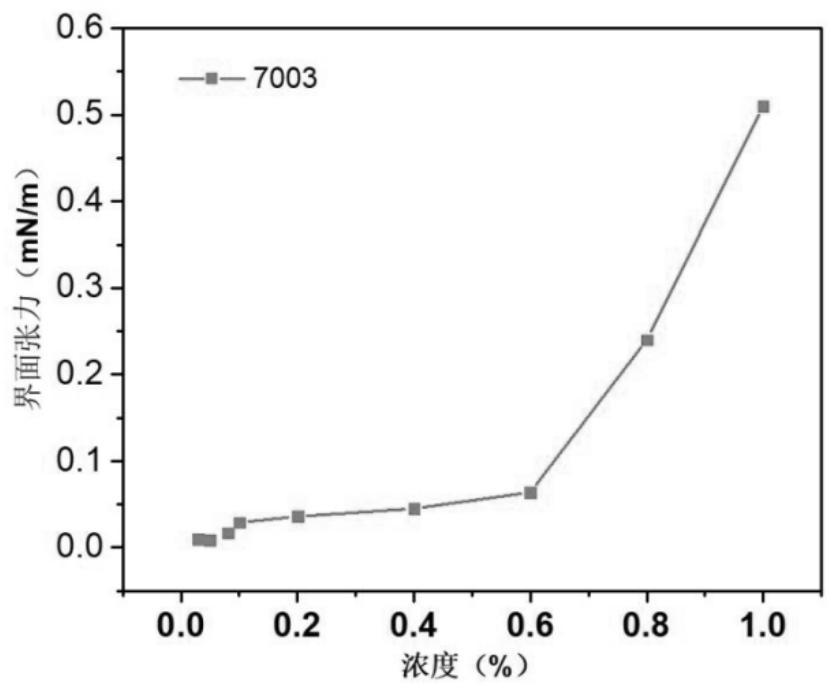

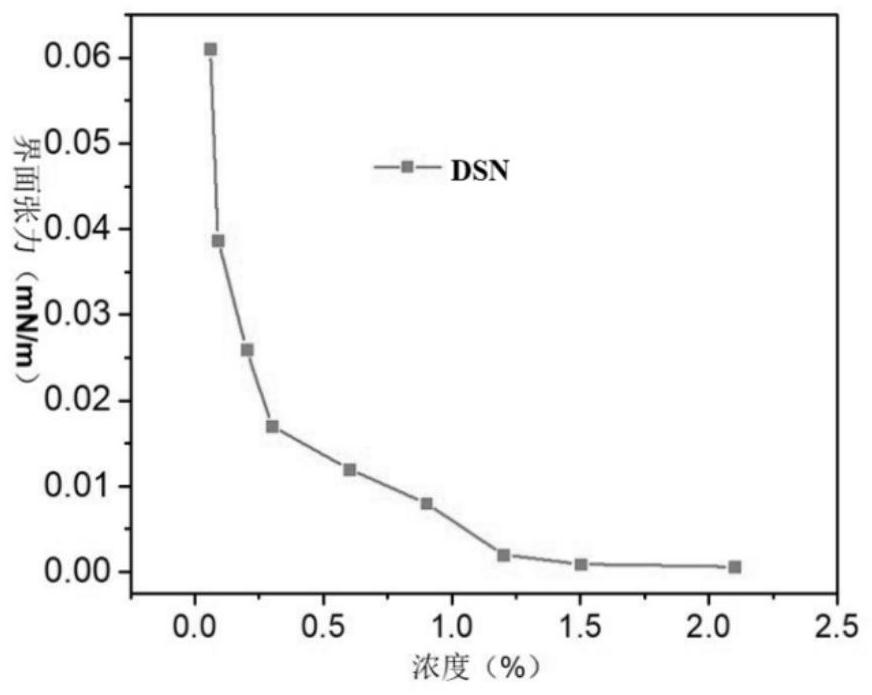

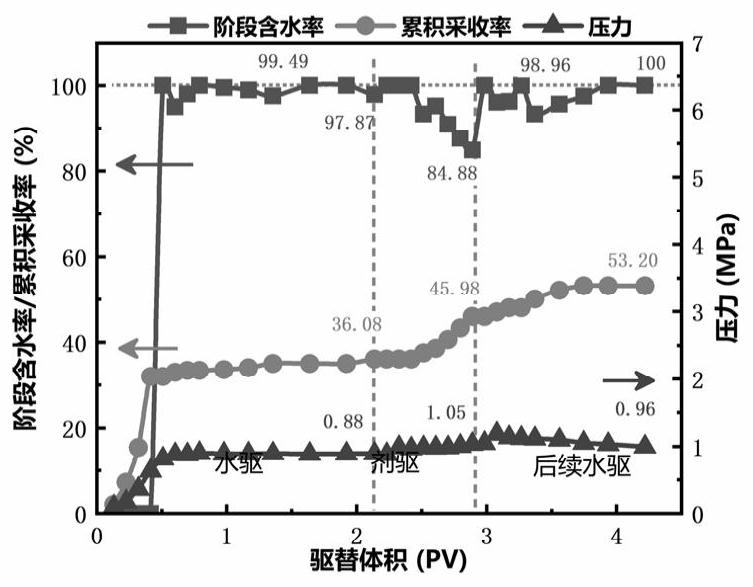

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com