Hydrophobic polypyrrole porous material as well as preparation method and application thereof

A porous material, polypyrrole technology, applied in chemical instruments and methods, other chemical processes, ion exchange, etc., can solve the problems of high energy consumption, small specific surface area, and incapable of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

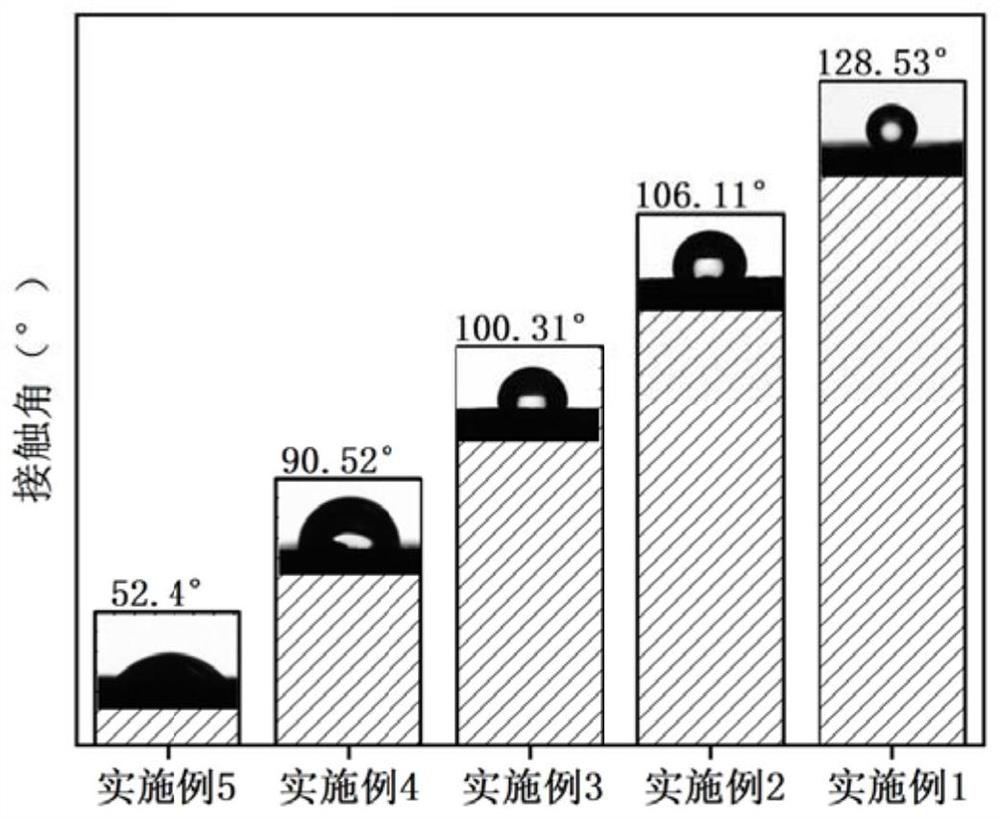

Embodiment 1

[0040] (1) Under inert gas atmosphere, dissolve 0.04mol Boc-D-phenylalanine and 0.04mol cholesterol in chloroform, then dissolve 0.04mol DCC and 0.004mol DMAP in 10mL dichloromethane, add dropwise The reaction system was reacted under ice bath conditions for 4 h and then reacted at room temperature for 20 h. The crude product cholesterol amino acid ester derivative 1 was obtained after the reaction solution was processed. Further, tetrahydrofuran: n-hexane=1:6 (v / v) was used as the mobile phase, and the reaction was carried out through The crude product was purified by column chromatography to obtain pure cholesterol amino acid ester derivative 1; the above cholesterol amino acid ester derivative 1 formed hydrochloride under the action of HCl, and then refluxed in benzene at 80 ° C for 4 hours to obtain cholesterol amino acid ester primary amine 1; Dissolve the obtained primary amine 1 of cholesterol amino acid ester in chloroform, then add a solution of furanaldehyde in chloro...

Embodiment 2

[0050] The imine bond-containing cholesterol derivative 1 obtained in Example 1 was added to a 4 mL sample bottle as a stabilizer, 0.015 mL of pyrrole and 500 mL of benzene were added, shaken and mixed evenly, and then 500 mL of FeCl was added. 3 The aqueous solution was fully mixed with a mixer, and after standing for a period of time, polypyrrole gel emulsion 2 was obtained.

[0051] The obtained polypyrrole gel emulsion 2 is polymerized, washed and dried to obtain a polypyrrole porous material 2 . Other steps are the same as in Example 1.

Embodiment 3

[0053] The imine bond-containing cholesterol derivative 1 obtained in Example 1 was added to a 4 mL sample bottle as a stabilizer, 0.043 mL of pyrrole and 300 mL of benzene were added, shaken and mixed evenly, and then 700 mL of FeCl was added. 3 The aqueous solution was fully mixed with a mixer, and after standing for a period of time, polypyrrole gel emulsion 3 was obtained.

[0054] The obtained polypyrrole gel emulsion 3 is polymerized, washed and dried to obtain a polypyrrole porous material 3 . Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com