Motor moving device for cooperating with hydraulic motor test bench and control method thereof

A technology of hydraulic motor and mobile device, which is applied to fluid pressure actuating devices, optical devices, measuring devices, etc., can solve the problems of low safety, increased staff burden, and difficult adjustment, and achieves improved automation and intelligence. , The effect of reducing complex operation steps and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

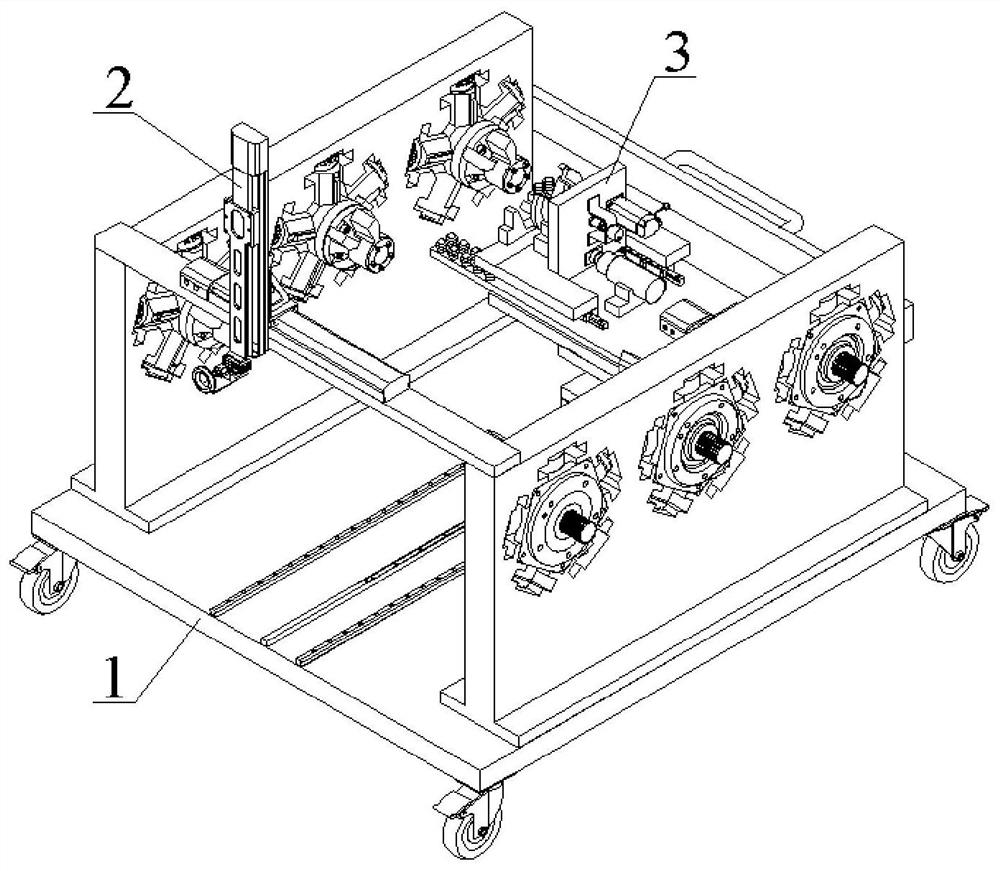

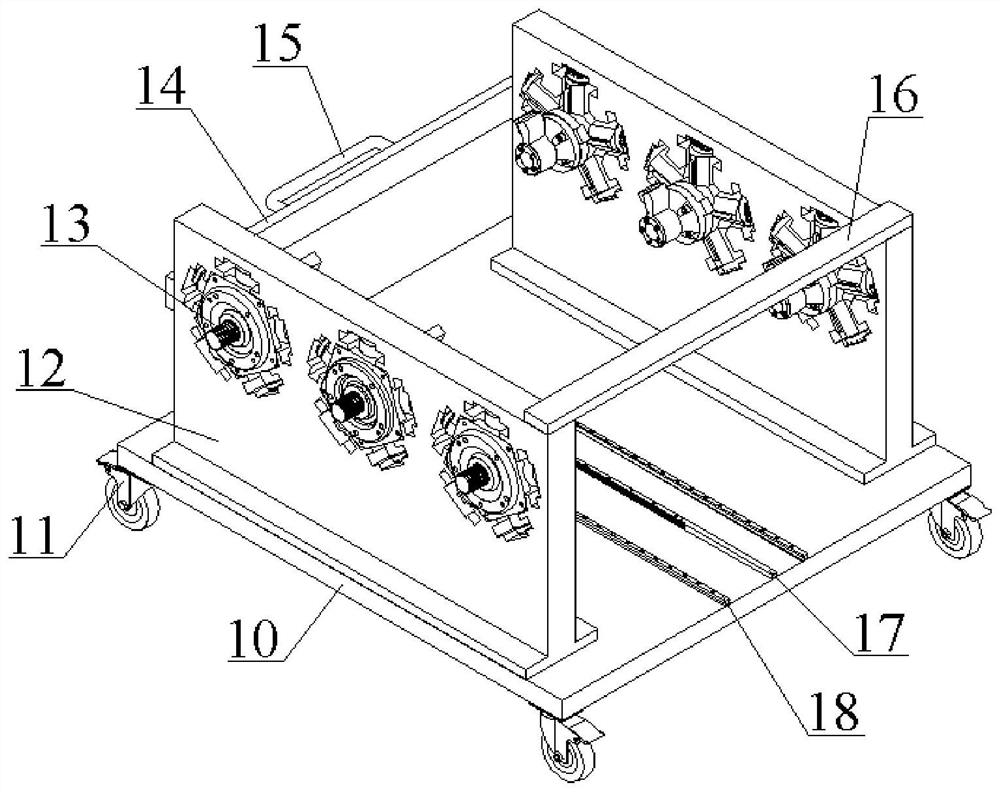

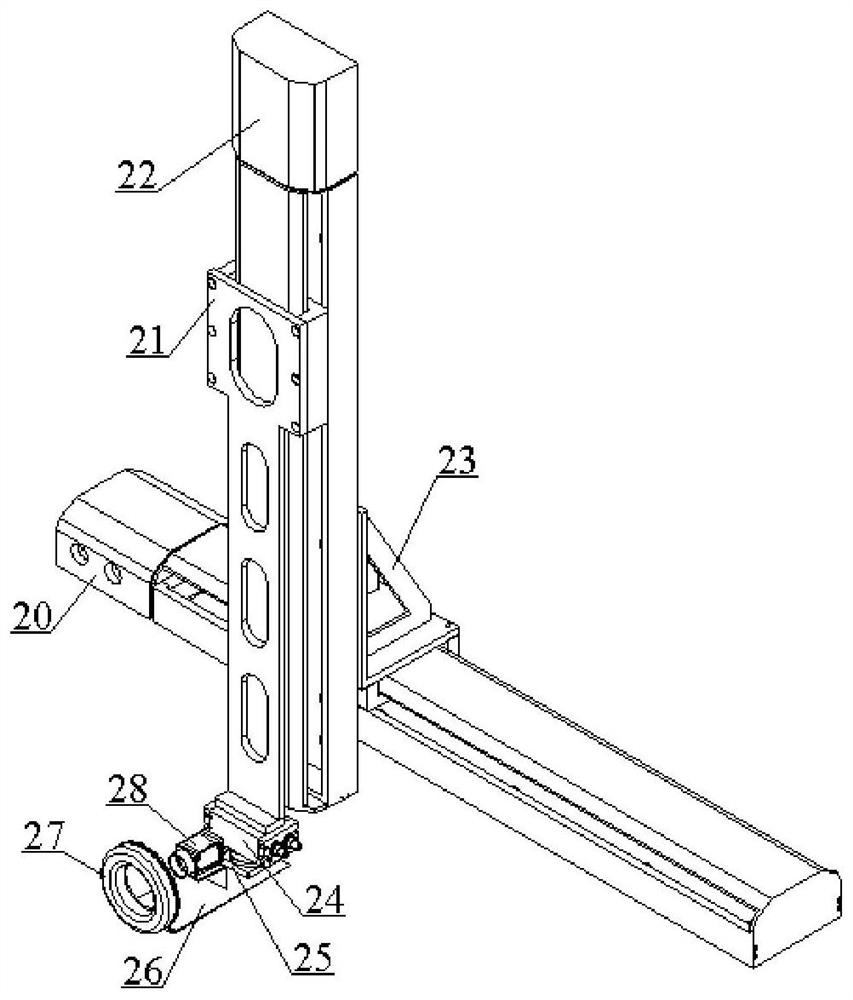

[0102] like Figure 1-3 As shown in FIG. 5 , a motor moving device for matching with a hydraulic motor test bench includes a motor storage device 1 , a visual inspection system 2 and a material moving device 3 . The horizontal linear module 20 of the visual inspection system 2 is arranged on the visual inspection system mounting plate 16 of the motor storage device 1. The first pinion 3003 of the moving device 3 meshes with the rack 17 of the motor storage device 1, and passes through the first pinion 3003 of the motor storage device 1. The sliding block 3000 is installed on the motor storage device 1 in cooperation with the first guide rail 18 , and can move along the first guide rail 18 at the same time.

[0103] like figure 2 As shown, the motor storage device 1 includes a storage rack mounting plate 10 , rollers 11 , and a motor storage r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com