Hydrogen storage cylinder or oxygen storage cylinder manufactured by spinning titanium alloy pipe

A technology for titanium alloy tubes and oxygen cylinders, which can be used in fixed-capacity gas storage tanks, hydrogen technology, pressure vessels, etc., and can solve problems such as cracking and embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

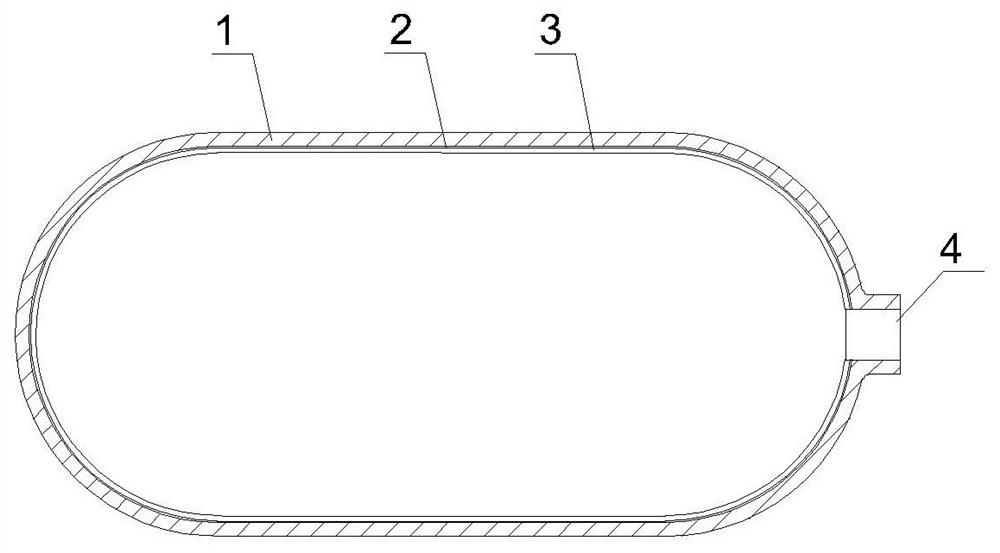

[0026] Titanium alloy tube rotor is made of hydrogen storage cylindrical cylinders or storage oxygen cylindrical section of the other end of the seal. figure 1 As shown, 1 is: 1 is a hydrogen storage cylinder or an oxygen cylinder opening of the other end of the end seal, 2 is the glue, 3 is an inner resin bottle, 4 is a hydrogen storage cylinder or an oxygen cylinder.

[0027] When making, the rotary press makes the titanium alloy tube into a hydrogen storage cylinder or a hydrogen storage cylinder 1 opening of the other end of the seal, a hydrogen storage cylinder or a hydrogen storage cylinder of the other end of the seal, or a hydrogen storage cylinder 1 inner cavity glue 2, one end sealing The hydrogen storage cylinder or the inner chamber of the opening of the other end is formed in the inner chamber of the inner chamber, and the inner resin bottle 3 is bonded to the hydrogen storage cylinder or the hydrogen storage cylinder 1 opening of the other end of the end.

Embodiment 2

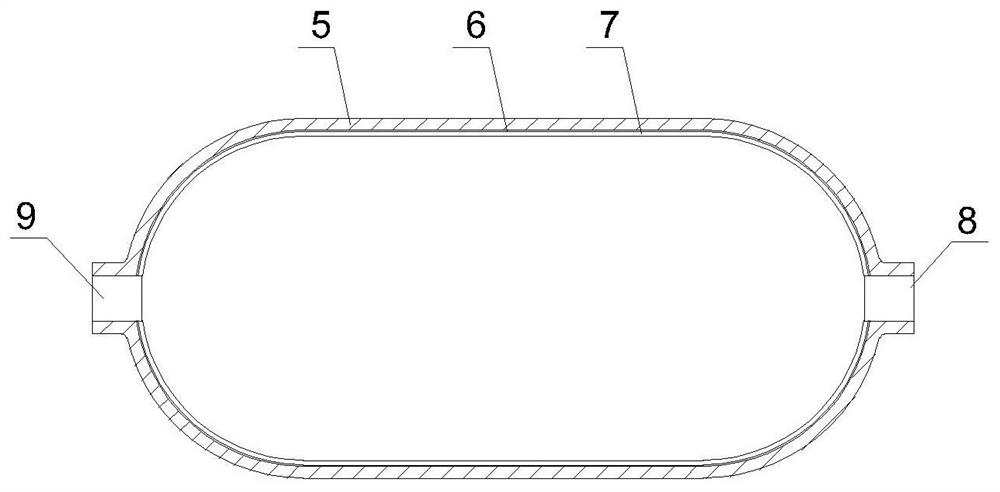

[0029] Titanium alloy tube rotation is made of two ends of the hydrogen storage gas cylinder or the oil storage cylinder section, such as figure 2 As shown, in which: 5 is a hydrogen storage cylinder or an oxygen cylinder opening of both ends, 7 is a gum, 7 is an inner resin bottle, 8 is a hydrogen storage cylinder or a storage oxygen cylinder, 9 is the other end to hydrogen storage cylinders or oxygen Bottle.

[0030] When making, the rotary press is rotated by the hydrogen storage cylinders or the hydrogen storage cylinders 5, the hydrogen storage cylinders 5, the two-end opening of the oxygen cylinder 1, and the reservoir of the two ends open. Hydrogen cylinders or oxygen cylinders 5 inner cavities are produced in the inner resin bottle 7, and the glue bottle 7 is bonded to the hydrogen storage cylinder or the hydrogen storage cylinder 5 of both ends.

Embodiment 3

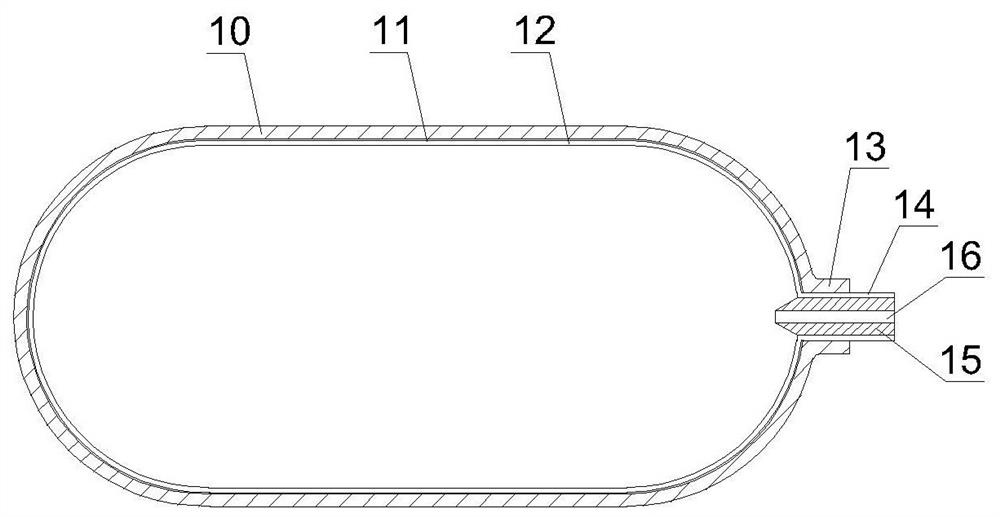

[0032] Titanium alloy tube rotor is schematically formed by hydrogen storage cylinders or gas storage cylinders in the other end of the opening. image 3 As shown,: 10 is a hydrogen storage cylinder or an oxygen cylinder opening of the other end opening of one end, 11 is a glue, 12 is an inner resin bottle, 13 is a hydrogen storage cylinder or a storage oxygen cylinder, 14 is a hollow resin column, 15 is Blowing air mouth, 16 is blown mouth.

[0033] When making, the rotary press is rotatable into a hydrogen storage cylinder or a hydrogen storage cylinder 10, a hydrogen storage cylinder 10, an end, one end, and a hydrogen storage gas cylinder 10, a hydrogen storage gas cylinder 10, and hydrogen storage gas. The hollow resin pillar 14 is loaded into the bottle or the gas storage cylinder portion, and the blowing air nozzle 15 enters the hollow resin post 14, and the blow mold 16 enters the blow molding gas, the hollow resin post 14 expands, and produces one end seal the other end op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com