Double-path parallel super-resolution laser direct writing device based on light field regulation and control

A super-resolution, two-way technology, applied to the originals for opto-mechanical processing, photolithographic process exposure devices, laser welding equipment, etc. Problems such as range processing and processing speed cannot be comparable to achieve the effect of speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

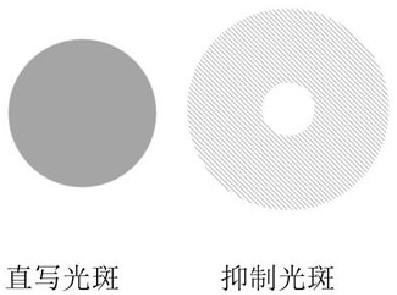

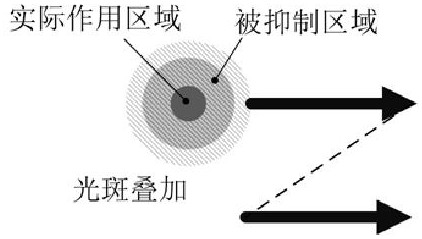

[0023] The basic principle of the present invention is as figure 1 As shown, it includes a direct writing beam and a suppression beam, and each beam is decomposed into p component and s component orthogonally. The p-component of the direct writing beam is phase-modulated with a left-tilt, and the s-component is phase-modulated with a right-tilt. After passing through the objective lens, the two polarization components of the direct writing beam are focused into two separate direct writing spots. The p-component of the suppressed beam is modulated by the left-tilt phase and the vortex phase, and the s-component is modulated by the right-tilt phase and the vortex phase. After passing through the objective lens, the two polarization components of the suppression beam are focused into two separate hollow suppression spots.

[0024] Such as Figure 2a-Figure 2c As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com