Modified polyetheretherketone as well as preparation method and application thereof

The technology of polyetheretherketone and sulfonated polyetheretherketone is applied in the field of modified polyetheretherketone and its preparation, and can solve the problems of limited improvement of biological activity, decreased mechanical properties, unfavorable performance of polyetheretherketone, etc. Achieve the effect of inducing osteogenic differentiation of stem cells, good biological activity and osteoinductive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

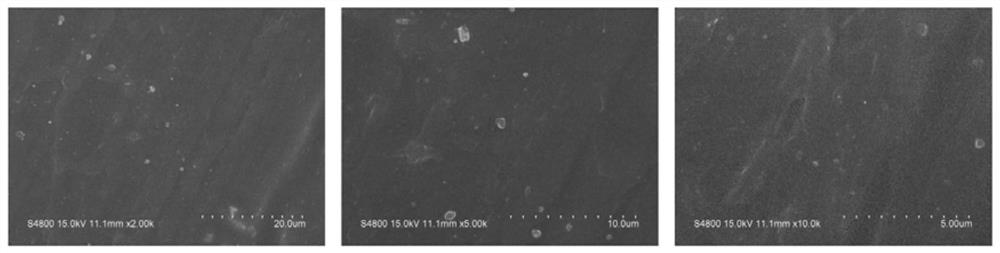

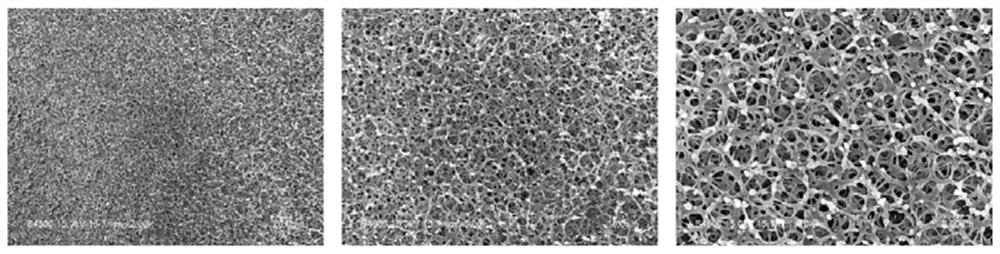

[0040] The preparation method of the modified polyether ether ketone provided in this embodiment comprises the following steps:

[0041] 1. Sulfonation: Add concentrated sulfuric acid to the polyetheretherketone sheet for sulfonation. The sulfonation time is 3 minutes to obtain sulfonated polyetheretherketone. Based on the mass of 1g of polyetheretherketone sheet, the concentrated The amount of sulfuric acid used is not less than 100mL;

[0042] 2. Active treatment: add sulfonated polyether ether ketone to bioglass sol for 5 minutes, take it out and dry it, and repeat this action three times; based on the mass of 1g polyetheretherketone sheet, the bioglass The amount of sol used is 50mL;

[0043] 3. Heat treatment: Heat treatment at 120°C for 24 hours to obtain modified polyether ether ketone.

[0044] The biological glass sol in the present embodiment adopts calcium source, silicon source, magnesium source, obtains biological glass sol by sol-gel method under acidic conditi...

Embodiment 2

[0060] The preparation method of the modified polyether ether ketone provided in this embodiment comprises the following steps:

[0061] 1. Sulfonation: Add concentrated sulfuric acid to the polyetheretherketone sheet for sulfonation. The sulfonation time is 3 minutes to obtain sulfonated polyetheretherketone. Based on the mass of 1g of polyetheretherketone sheet, the concentrated The amount of sulfuric acid used is not less than 100mL;

[0062] 2. Active treatment: add sulfonated polyether ether ketone to bioglass sol for 5 minutes, take it out and dry it, and repeat this action three times; based on the mass of 1g polyetheretherketone sheet, the bioglass The amount of sol used is 50mL;

[0063] 3. Heat treatment: Heat treatment at 150°C for 24 hours to obtain modified polyether ether ketone.

[0064] The biological glass sol in the present embodiment adopts calcium source, silicon source, magnesium source, obtains biological glass sol by sol-gel method under acidic conditi...

Embodiment 3

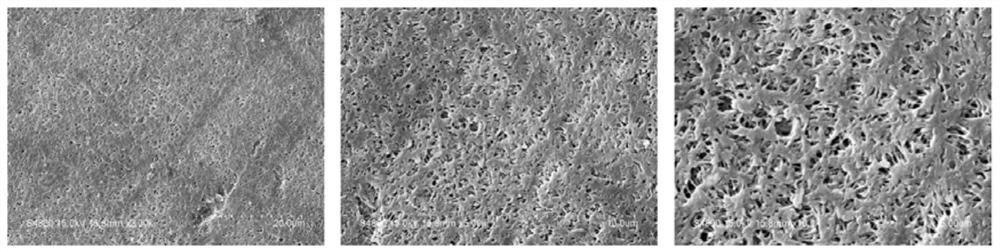

[0066] The preparation method of the modified polyether ether ketone provided in this embodiment comprises the following steps:

[0067] 1. Sulfonation: Add concentrated sulfuric acid to the polyetheretherketone sheet for sulfonation. The sulfonation time is 3 minutes to obtain sulfonated polyetheretherketone. Based on the mass of 1g of polyetheretherketone sheet, the concentrated The amount of sulfuric acid used is not less than 100mL;

[0068] 2. Active treatment: add sulfonated polyether ether ketone to bioglass sol for 5 minutes, take it out and dry it, and repeat this action three times; based on the mass of 1g polyetheretherketone sheet, the bioglass The amount of sol used is 50mL;

[0069] 3. Heat treatment: Heat treatment at 120°C for 24 hours to obtain modified polyether ether ketone.

[0070] The biological glass sol in the present embodiment adopts calcium source, silicon source, magnesium source, obtains biological glass sol by sol-gel method under acidic conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com