Environment-friendly laundry particles and preparation method thereof

An environmentally friendly, particle-based technology, applied in chemical instruments and methods, detergent materials, detergent compositions, etc., can solve the problems of unfriendly environment, and achieve the goal of improving environmental friendliness, high surface activity, and increasing disintegration rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

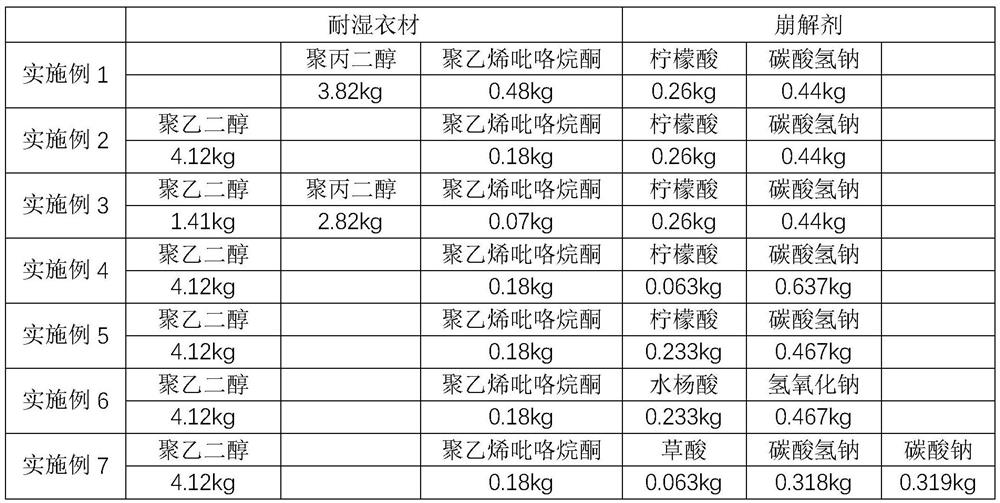

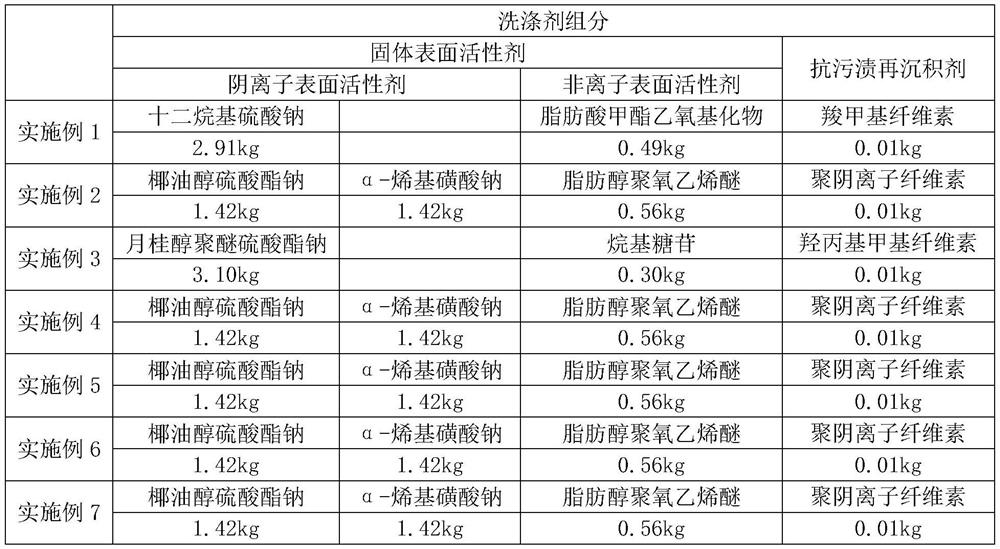

Embodiment 1-7

[0051] A kind of environment-friendly type laundry particle, is made through the following steps:

[0052] S1. Add the carrier matrix to the reaction kettle and heat the carrier matrix to a molten state. At this time, the temperature of the carrier matrix is between 65-80°C;

[0053] S2. Adding an anti-stain redeposition agent, a solid surfactant and a disintegrant in sequence to the molten carrier matrix, stirring evenly and then cooling down to 60° C. to obtain a granulated slurry;

[0054] S3. Inputting the cooled granulation slurry into a molding granulator for granulation to obtain environment-friendly laundry granules.

[0055] The specific raw materials selected in Examples 1-7 and their addition amounts are shown in Table 1 and Table 2.

[0056] Regarding the heating temperature in step S1, those skilled in the art should understand that due to the differences in the melting points and proportions of different raw materials, the heating temperature in actual operati...

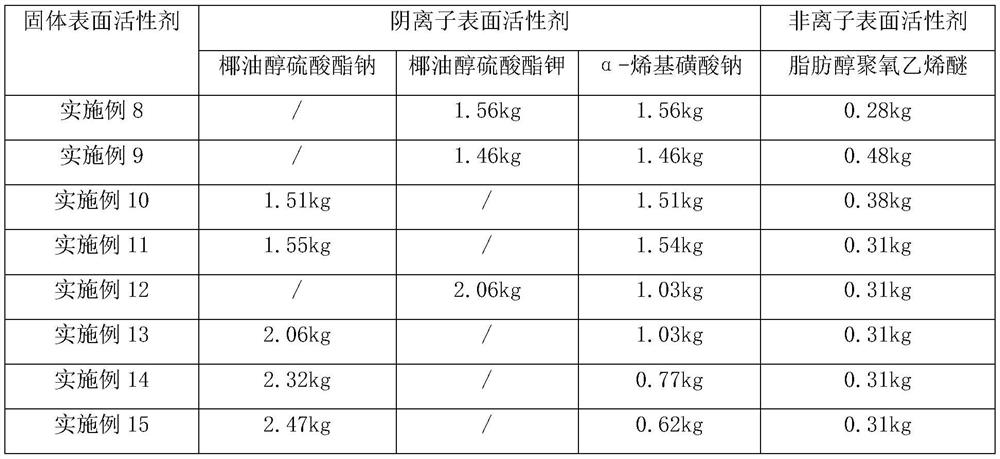

Embodiment 8-15

[0063] An environment-friendly laundry particle, the only difference from Example 7 is the formulation of the solid surfactant. The specific formulation of the solid surfactant used in Examples 8-15 is shown in Table 3.

[0064] The specific formulation table of solid surfactant in table 3 embodiment 8-15

[0065]

Embodiment 16-18

[0067] An environment-friendly laundry granule, the only difference from Example 13 is that in step S2, detergent builders are added to the liquid moisture-resistant clothing. The specific formula of the detergent builder used in Examples 16-18 is shown in Table 4.

[0068] The specific formula table of washing builder in table 4 embodiment 16-18

[0069] detergent builder Bentonite 4A zeolite corn starch Anhydrous Sodium Sulfate Example 16 0.3kg / / / Example 17 0.3kg 0.2kg / / Example 18 0.3kg 0.2kg 0.3kg 0.4kg

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com