Aluminum alloy anodic oxidation surface treatment process

A technology of anodic oxidation and surface treatment, applied in the direction of anodic oxidation, surface reaction electrolytic coating, coating, etc., can solve the problem of single function of oxide film, and achieve the effect of good transparency, good adsorption and easy coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

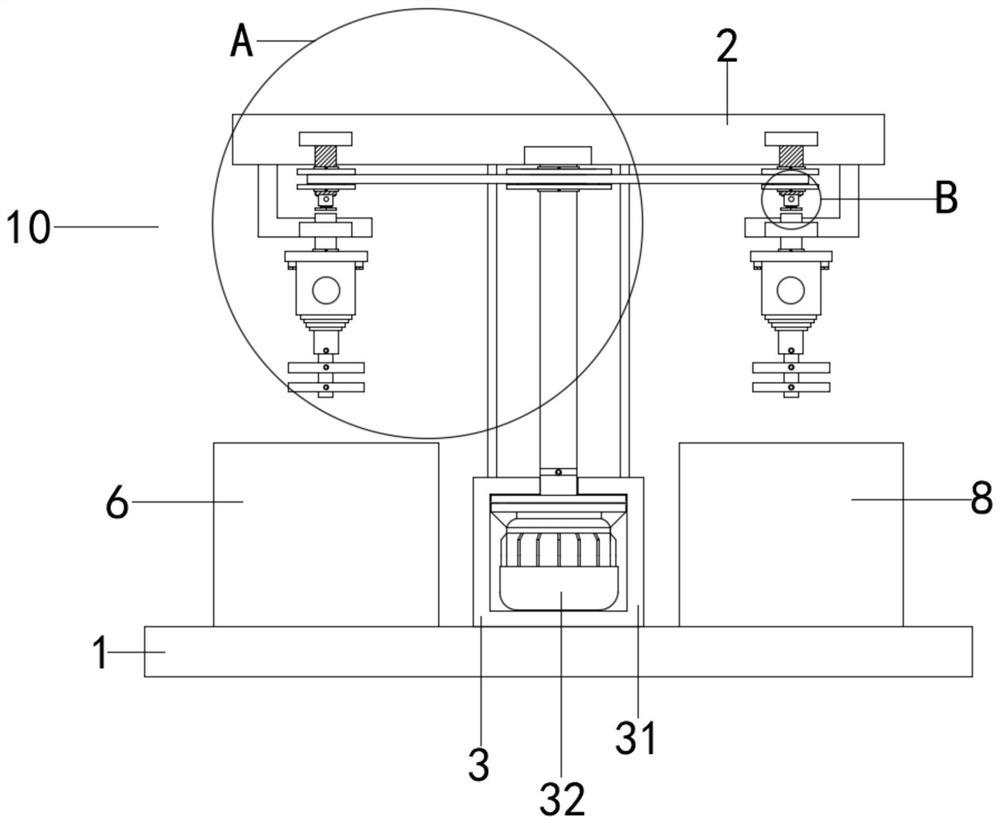

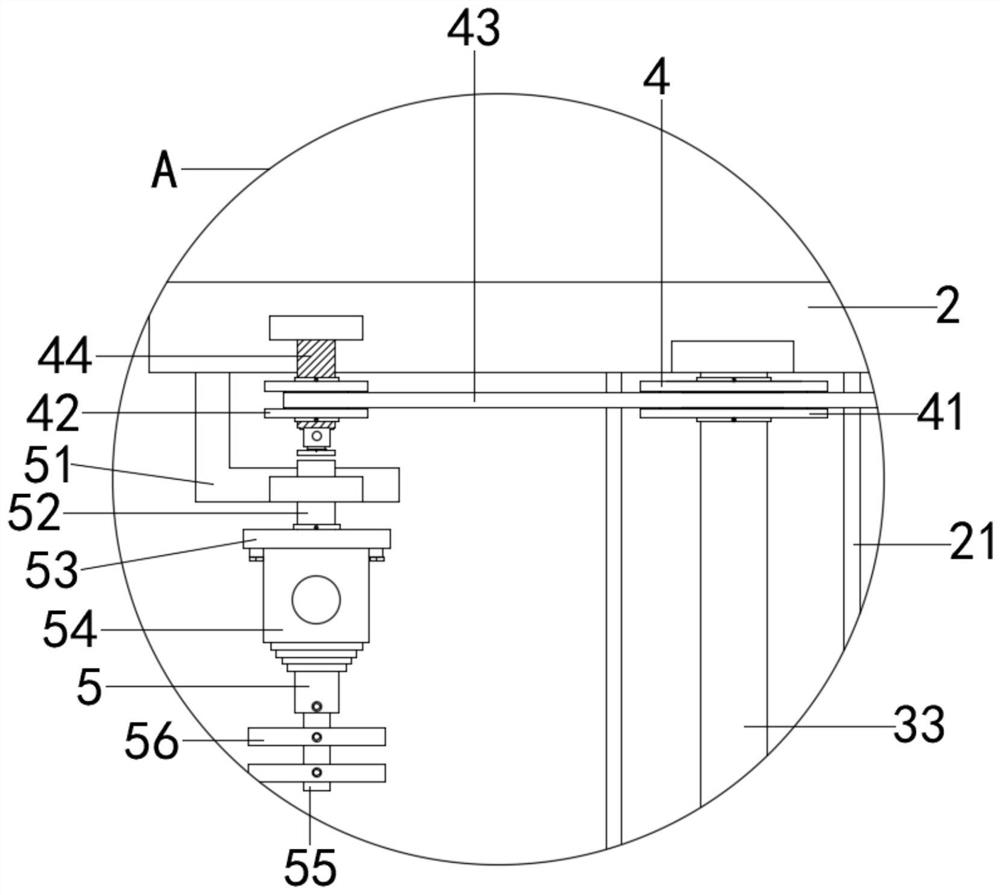

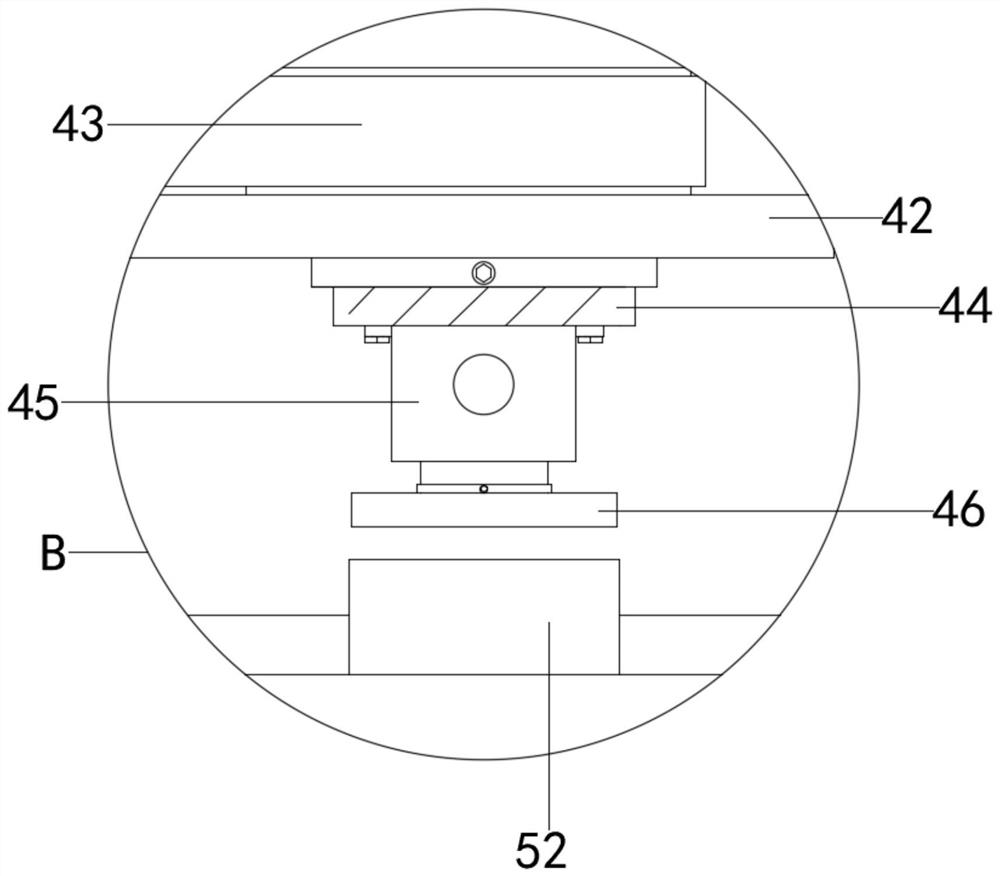

[0037] Refer to attached Figure 1-Figure 8 , a kind of aluminum alloy anodic oxidation surface treatment process provided by the present invention, comprises concrete steps as follows:

[0038] S1, to clean the aluminum alloy, by using carbon tetrachloride, trichlorethylene, gasoline or toluene as the cleaning agent, immerse the aluminum alloy die-casting parts, scrub with a brush, then air-dry, and then immerse in water, so that the oil is removed After exhaustion, rinse with hot water at 80°C immediately. If a black film is formed on the surface, soak it in 30% nitric acid solution for 18 seconds to remove the black film. Finally, rinse with cold water and immerse in distilled water;

[0039] S2, carry out alkali etching on aluminum alloy, carry out alkali etching on aluminum alloy by using aluminum material alkali etchant, aluminum material alkali etchant is composed of sodium hydroxide, ammonium bifluoride, gluconate and dextrin, wherein sodium hydroxide, The ratio of am...

Embodiment 2

[0051] Refer to attached Figure 1-Figure 8 , a kind of aluminum alloy anodic oxidation surface treatment process provided by the present invention, comprises concrete steps as follows:

[0052] S1, to clean the aluminum alloy, by using carbon tetrachloride, trichlorethylene, gasoline or toluene as the cleaning agent, immerse the aluminum alloy die-casting parts, scrub with a brush, then air-dry, and then immerse in water, so that the oil is removed After exhaustion, rinse with hot water at 85°C immediately. If a black film is formed on the surface, soak it in 32% nitric acid solution for 20 seconds to remove the black film. Finally, rinse with cold water and immerse in distilled water;

[0053] S2, carry out alkali etching on aluminum alloy, carry out alkali etching on aluminum alloy by using aluminum material alkali etchant, aluminum material alkali etchant is composed of sodium hydroxide, ammonium bifluoride, gluconate and dextrin, wherein sodium hydroxide, The ratio of am...

Embodiment 3

[0057] Refer to attached Figure 1-Figure 8 , a kind of aluminum alloy anodic oxidation surface treatment process provided by the present invention, comprises concrete steps as follows:

[0058] S1, to clean the aluminum alloy, by using carbon tetrachloride, trichlorethylene, gasoline or toluene as the cleaning agent, immerse the aluminum alloy die-casting parts, scrub with a brush, then air-dry, and then immerse in water, so that the oil is removed After exhaustion, rinse with hot water at 90°C immediately. If a black film is formed on the surface, soak it in 34% nitric acid solution for 22 seconds to remove the black film. Finally, rinse with cold water and immerse in distilled water;

[0059] S2, carry out alkali etching on aluminum alloy, carry out alkali etching on aluminum alloy by using aluminum material alkali etchant, aluminum material alkali etchant is composed of sodium hydroxide, ammonium bifluoride, gluconate and dextrin, wherein sodium hydroxide, The ratio of am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com