Variable-cross-section disc cutter ring and design and manufacturing method thereof

A disc-shaped hob and variable cross-section technology, applied in design optimization/simulation, cutting tools, mining equipment, etc., can solve problems such as complex rock mass structure, knife ring impact, wear failure, etc., to improve rock adaptability and impact Load capacity and life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

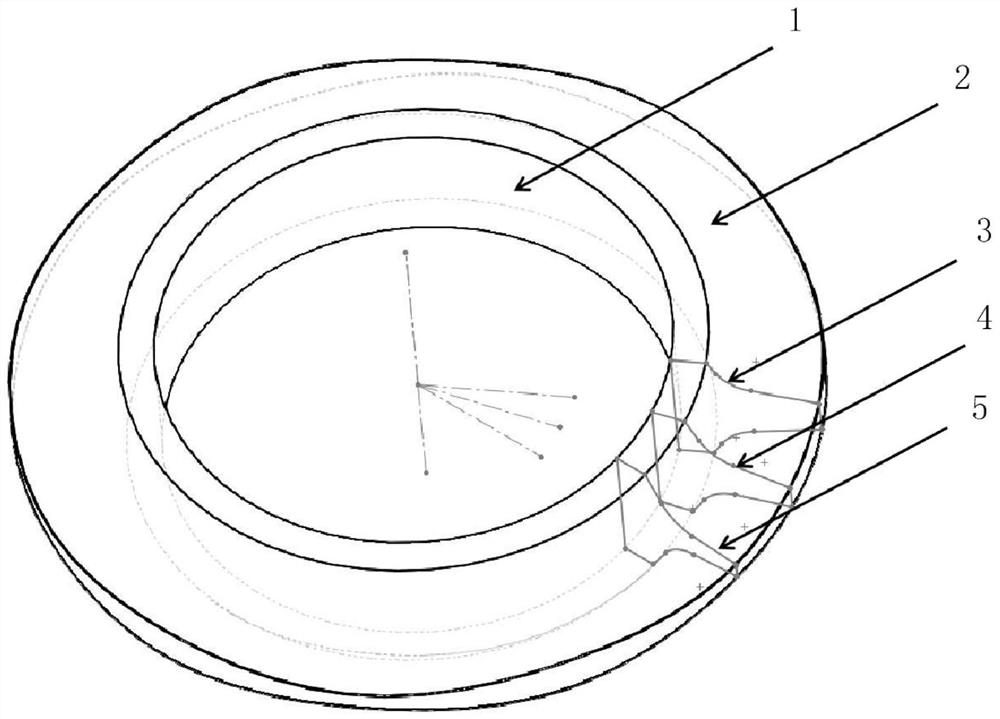

[0064] see figure 1 Shown:

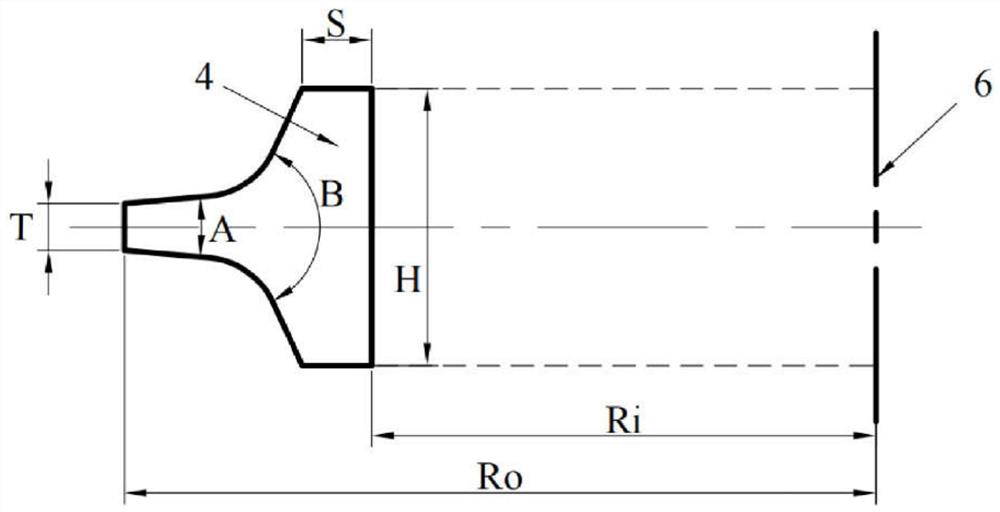

[0065] A disc-shaped hob cutter ring with variable cross-section provided by the present invention includes a blade body 1 and a blade 2, the blade body 1 is a regular annular standard body of revolution, the blade 2 is arranged on the outer ring of the blade body 1, and the blade 2 is a rotary body whose radial cross-sectional profile changes regularly along the circumferential direction, and the blade width, blade angle, and blade shoulder angle change regularly along the circumferential direction.

[0066] The change of the law is that when the knife ring rotates one circle, the radial cross-sectional profile of the blade 2 experiences several complete change cycles along the circumferential direction according to a certain frequency of change, and the change rule of the radial cross-sectional profile of the blade 2 in each change cycle is the same , that is, the change range of the blade width is the same in each change period, the change rang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com