Cooling device provided with multi-angle adjusting function and used for wafer baking

A cooling device, multi-angle technology, applied in household refrigeration devices, cooling fluid circulation devices, drying and other directions, can solve the problems of easy residual moisture in wafers, take a long time, slow cooling speed, etc., to shorten the cooling needs. time, avoid the impossible, improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

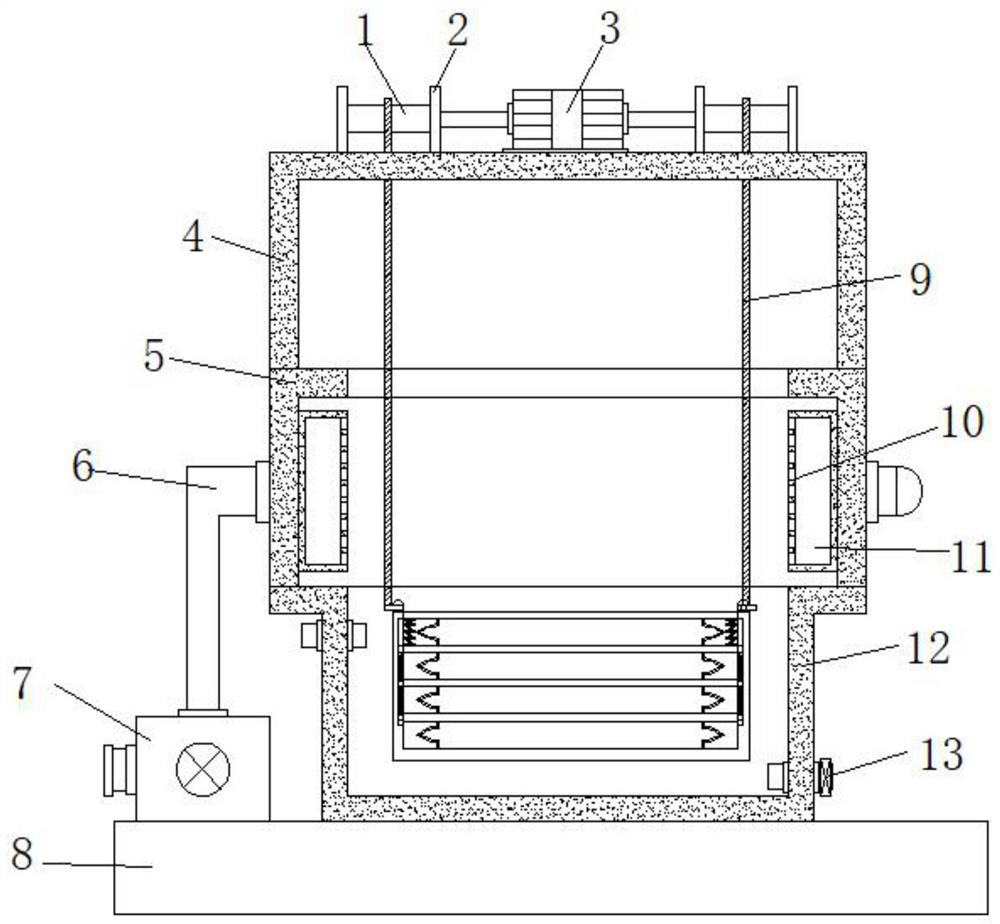

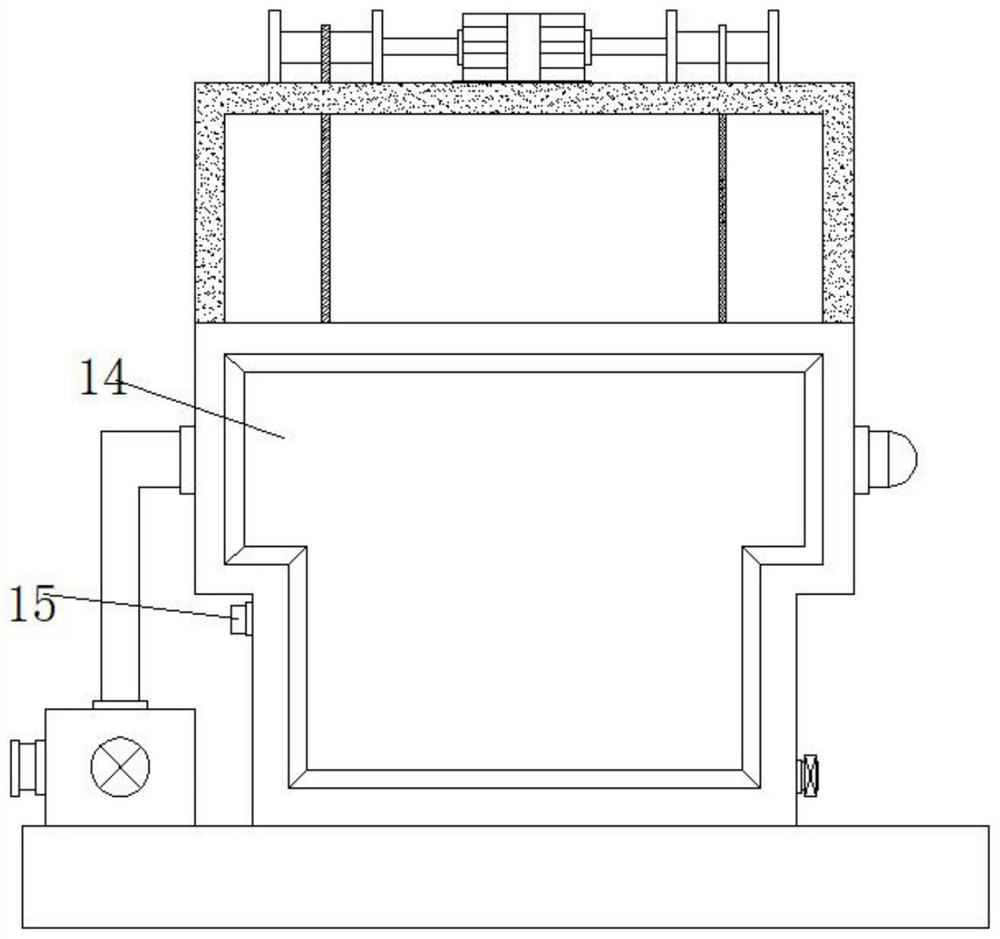

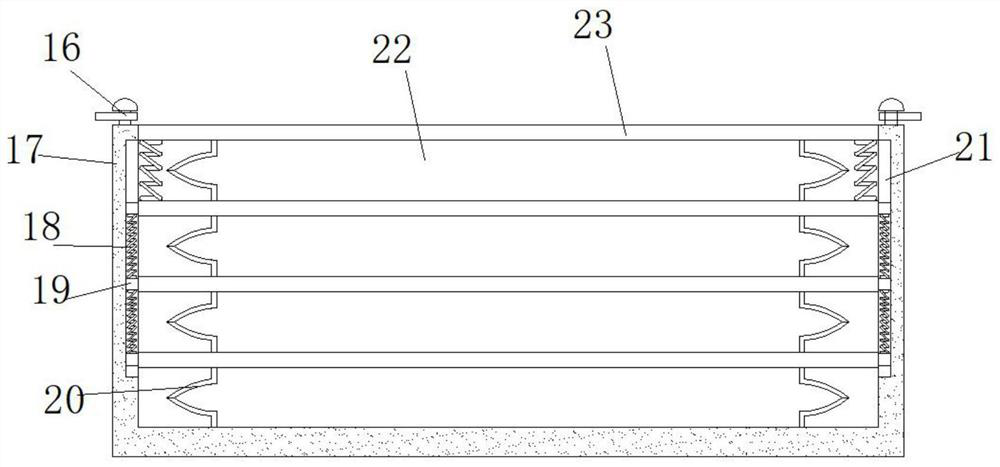

[0023] Example: refer to Figure 1-3 , including a base 8, the top of the base 8 is welded with a water-cooled warehouse 12, the water-cooled warehouse 12 is a cylindrical structure and the top of the water-cooled warehouse 12 is open, and the side wall of the water-cooled warehouse 12 is welded on the top of the water-cooled warehouse 12. The water injection pipe 15, the other side wall of the water cooling chamber 12 is located at the bottom of the water cooling chamber 12 and is welded with a drain pipe 13, the drain pipe 13 and the water injection pipe 15 are all provided with a stop valve, the water cooling chamber 12 has a built-in shelf 17, and the shelf 17 is Cylindrical structure and the outer wall of placing frame 17 all adopt hollow structure, and the front and rear side walls of placing frame 17 are all set in open structure, and the inner side wall of placing frame 17 is provided with chute 21, and the quantity of chute 21 is four groups and Arranged in a circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com