Method for reducing leakage rate and improving transfer rate of tannin component of DASANGUO

A technology of leakage rate and transfer rate, which can be used in medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, pharmaceutical formulations, etc. Quality extraction and purification, unsuitable for industrial production and other problems, to meet the needs of industrial production, improve the transfer rate and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0067] (a) Soak the HPD-400 type macroporous resin column in 95vol% ethanol aqueous solution for 4 hours, perform dynamic elution with 4BV of 95vol% ethanol aqueous solution, and then wash with water until the effluent has no alcohol smell;

[0068] (b) Soak in 5wt% hydrochloric acid aqueous solution for 3 hours, perform dynamic eluting with 3BV of 5wt% hydrochloric acid aqueous solution, and then wash with water until the effluent is close to neutral;

[0069] (c) Soak in 5wt% NaOH aqueous solution for 3 hours, perform dynamic elution with 3BV of 5wt% NaOH aqueous solution, and then wash with water until the effluent is neutral;

[0070] (d) Wash with 95vol% ethanol aqueous solution until the eluent and water are mixed at a volume ratio of 1:5 and there is no white turbidity, and then wash with water until the effluent has no alcohol smell, and an activated HPD-400 macroporous resin column is obtained.

Embodiment 1

[0072] 1) Take 30 g each of Amla emblica, Myrobalan myrobalan, and Myrobalan mulberry, mix, pulverize, and pass through a 10-mesh sieve to obtain a medicinal powder mixture. The drug powder mixture was placed in 70 vol% ethanol aqueous solution at 50° C. for 3 extractions, 6 hours each time. The volume ratio of the powder mixture to the aqueous ethanol solution is 1:10. Suction filtration, combined filtrates, to obtain Dasan fruit tannin extract. Put the tannin extract of Dasan fruit at 40°C, concentrate under reduced pressure to contain 0.2g of crude drug per ml of concentrated solution, and then centrifuge at 3000r / min for 30min to obtain a supernatant.

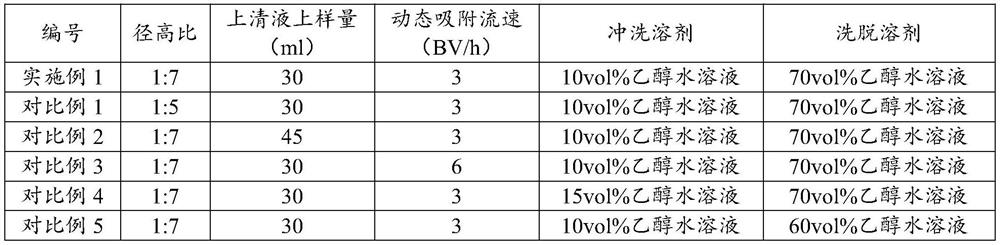

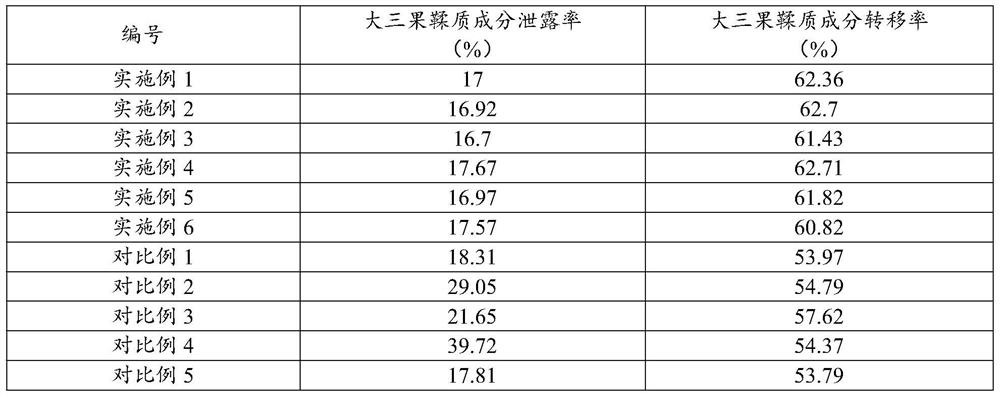

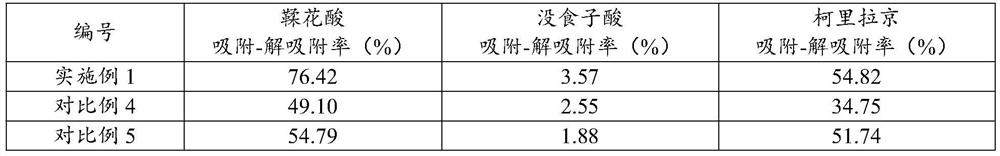

[0073] 2) Take 30ml of the supernatant and activate the HPD-400 macroporous resin column (the activation process is the same as that of Preparation Example 1, the diameter-to-height ratio is 1:7, and the wet volume of the resin is 20ml) for dynamic adsorption, and the dynamic adsorption speed is 3BV / h. After the adsorpt...

Embodiment 2

[0076] 1) Take 30 g each of Amla emblica, Myrobalan myrobalan, and Myrobalan mulberry, mix, pulverize, and pass through a 10-mesh sieve to obtain a medicinal powder mixture. The drug powder mixture was placed in 70 vol% ethanol aqueous solution at 50° C. for 3 extractions, 6 hours each time. The volume ratio of the powder mixture to the aqueous ethanol solution is 1:8. Suction filtration, combined filtrates, to obtain Dasan fruit tannin extract. Put the tannin extract of Dasan fruit at 40°C, concentrate under reduced pressure to contain 0.2g of crude drug per ml of concentrated solution, and then centrifuge at 3000r / min for 30min to obtain the supernatant.

[0077] 2) Take 30ml of the supernatant and activate the HPD-400 macroporous resin column (the activation process is the same as that of Preparation Example 1, the diameter-to-height ratio is 1:9, and the wet volume of the resin is 20ml) for dynamic adsorption, and the dynamic adsorption speed is 3BV / h. After the adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com