Ceramic carrier plate for polishing semiconductor wafers

A semiconductor and wafer technology, applied in the field of ceramic carrier, can solve the problems of low temperature and unaccelerated removal rate, and achieve the effects of simple and easy processing technology, accelerated chemical reaction speed, and small deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0030] It should be noted in advance that the term "comprising / comprising" used herein refers to the presence of features, elements, steps or components, but does not exclude the existence of one or more other features, elements, steps or components.

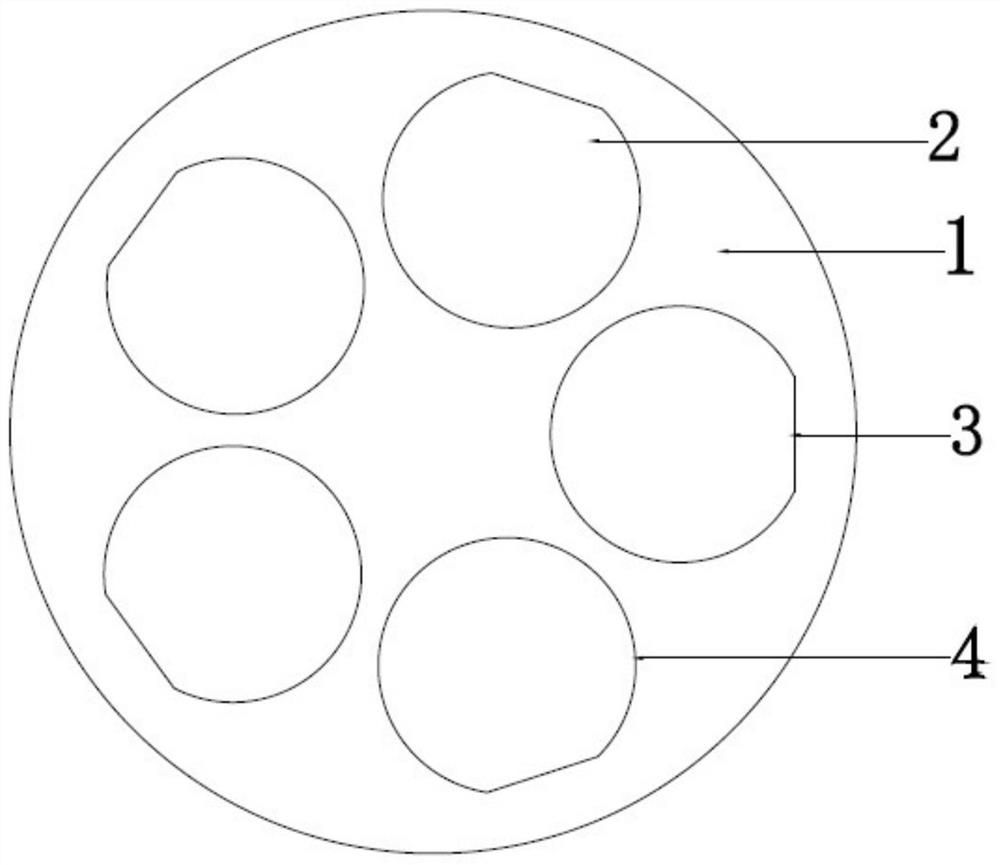

[0031] as attached figure 1 Shown is a top view of the ceramic carrier plate in an embodiment of the present invention, its structure includes: a plate body 1, a groove 2 located on the plate body, the groove and the plate body are integrated, and the top of the groove is flush with the plate body , and the grooves are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com