Equipment for preparing uniform size graphene oxide by one-step method

A kind of oxidized stone, uniform technology, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of long reaction time, wide size distribution of graphene oxide, consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

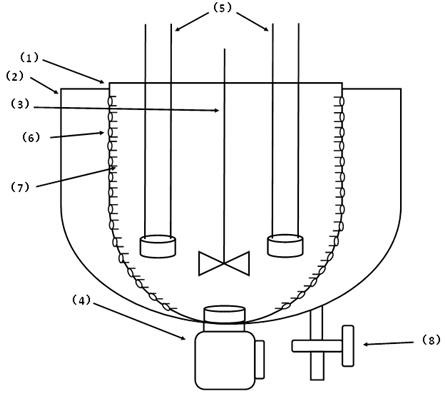

[0016] Figure 1-2 Shown an embodiment of the present invention, a kind of one-step method prepares the equipment of uniform size graphene oxide, comprises oxidation reactor 1, collecting tank 2, agitator 3 and first shear emulsification head 4, and oxidation reactor 1 is placed Inside the collection kettle 2, there is a hole 6 in the side wall of the oxidation reaction kettle 1; the agitator 3 extends into the center of the oxidation reaction kettle 1 from the top, and the first shear emulsification head 4 is inserted into the oxidation reaction kettle from the bottom of the collection kettle 2 1, there is a discharge valve 8 at the bottom of the collection kettle 2.

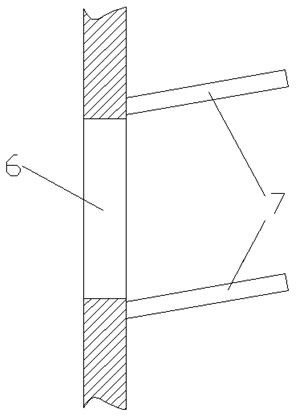

[0017] Wherein the side wall of the oxidation reaction kettle 1 is a perforated plate, the second shear emulsification head 5 is two, and extends into the inside of the oxidation reaction kettle from the side of the agitator, the diameter of the hole 6 is 10 microns, and there are a plurality of holes with the ...

Embodiment 2

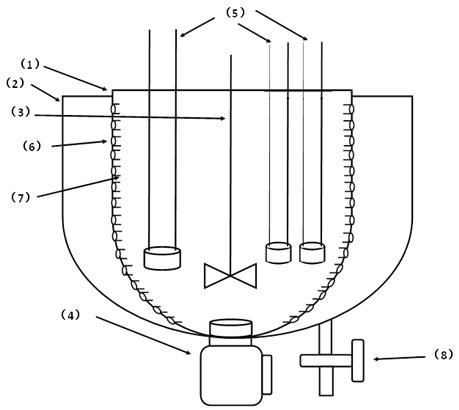

[0023] Such as Figure 2-3 Shown, a kind of one-step method prepares the equipment of uniform size graphene oxide, comprises oxidation reactor 1, collecting tank 2, stirrer 3 and first shearing emulsification head 4, and oxidation reactor 1 is placed in collecting tank 2 inside, oxidation There are holes 6 in the side wall of the reaction kettle 1; the agitator 3 extends into the center of the oxidation reaction kettle 1 from the top, and the first shear emulsification head 4 is inserted into the oxidation reaction kettle 1 from the bottom of the collection kettle 2, and the bottom of the collection kettle 2 There is a discharge valve 8.

[0024] Wherein the side wall of the oxidation reaction kettle 1 is a perforated plate, and the second shear emulsification head 5 is 3, which extend into the inside of the oxidation reaction kettle from the side of the agitator, and the diameter of the hole 6 is 30 microns, and the periphery of the hole 6 has a plurality of The baffle plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com