Composite cement with few silicate clinker components, and preparation method thereof

A technology for Portland clinker and Portland cement, which is applied in cement production and other directions to achieve the effects of good construction workability, low hydration heat, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

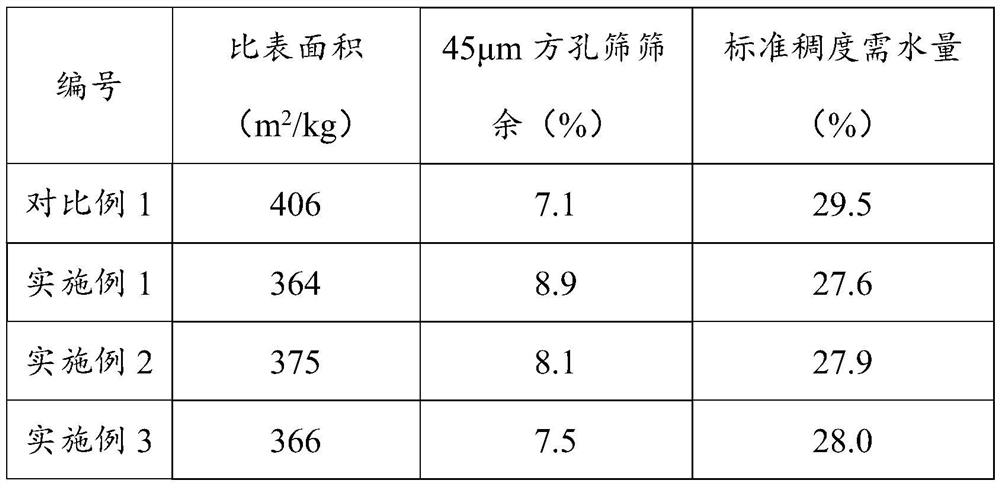

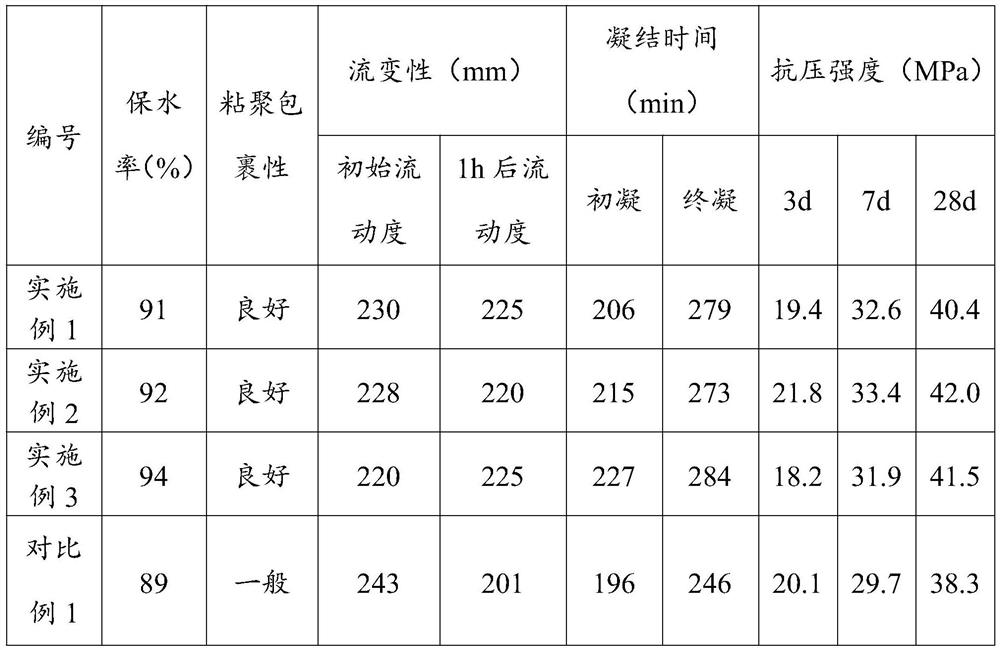

Embodiment 1

[0036] A composite cement with less silicate clinker component, comprising the following various preparation raw materials by weight percentage:

[0037] Portland cement clinker and gypsum 20%, slag powder (granulated blast furnace water quenching slag) 30%, fly ash 20%, limestone powder 20% and aluminosilicate-based mineral powder (including solid waste) 10%. In addition, in terms of mass ratio, the alkali metal salt and alkaline earth metal salt binder account for 4% of the total mass of the composite cement with less silicate clinker components, that is, the total mass of the alkali metal salt and alkaline earth metal salt binder accounts for 4% of the total mass of the silicate clinker component. 4% of the total mass of salt cement clinker and gypsum, slag powder, fly ash, limestone powder and aluminosilicate-based mineral powder.

[0038] Among them, the mass ratio of Portland cement clinker and gypsum is 4:1. Portland cement clinker: 3CaO SiO 2 Mineral accounts for 55%...

Embodiment 2

[0043] A composite cement with less silicate clinker component, comprising the following various preparation raw materials by weight percentage:

[0044] Portland cement clinker and gypsum 25%, slag powder 25%, fly ash 17%, limestone powder 21%, aluminosilicate-based mineral powder (including solid waste) 12%. In addition, in terms of mass ratio, the alkali metal salt and alkaline earth metal salt binder account for 3% of the total mass of the composite cement with less silicate clinker components, that is, the total mass of the alkali metal salt and alkaline earth metal salt binder accounts for 3% of the total mass of the silicate clinker component composite cement. 3% of the total mass of salt cement clinker and gypsum, slag powder, fly ash, limestone powder and aluminosilicate-based mineral powder.

[0045] Among them, the mass ratio of Portland cement clinker to gypsum is 4:1. Portland cement clinker: 3CaO SiO 2 Mineral accounts for 55%, 2CaO·SiO 2 Minerals account for ...

Embodiment 3

[0055] A composite cement with less silicate clinker component, comprising the following various preparation raw materials by weight percentage:

[0056] Portland cement clinker and gypsum 12%, slag powder 30%, fly ash 25%, limestone powder 22%, aluminosilicate-based mineral powder (including solid waste) 11%. In addition, in terms of mass ratio, alkali metal salts and alkaline earth metal salt binders account for 2.5% of the total mass of the composite cement with less silicate clinker components, that is, the total mass of alkali metal salts and alkaline earth metal salt binders accounts for 2.5% of the total mass of the silicate clinker component composite cement. 2.5% of the total mass of salt cement clinker and gypsum, slag powder, fly ash, limestone powder and aluminosilicate-based mineral powder.

[0057] Among them, the mass ratio of Portland cement clinker to gypsum is 2:1. Portland cement clinker: 3CaO SiO 2 Mineral accounts for 55%, 2CaO·SiO 2 Minerals account fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com