Shape memory porous material and preparation method and application thereof

A porous material and memory technology, applied in the field of materials, to achieve the effects of easy structure and performance, large volume deformation, and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. For the preparation method of zwitterionic shape memory polymers, see Example 1 of the authorized invention patent of application number CN201410720521.4, so as to obtain shape memory polymers with good biocompatibility and wet response shape memory properties; then the The zwitterionic shape memory polymer is dissolved in a mixed solvent with a volume ratio of DMF:water=5:5 to obtain a zwitterionic shape memory polymer solution with a concentration of 1 wt%.

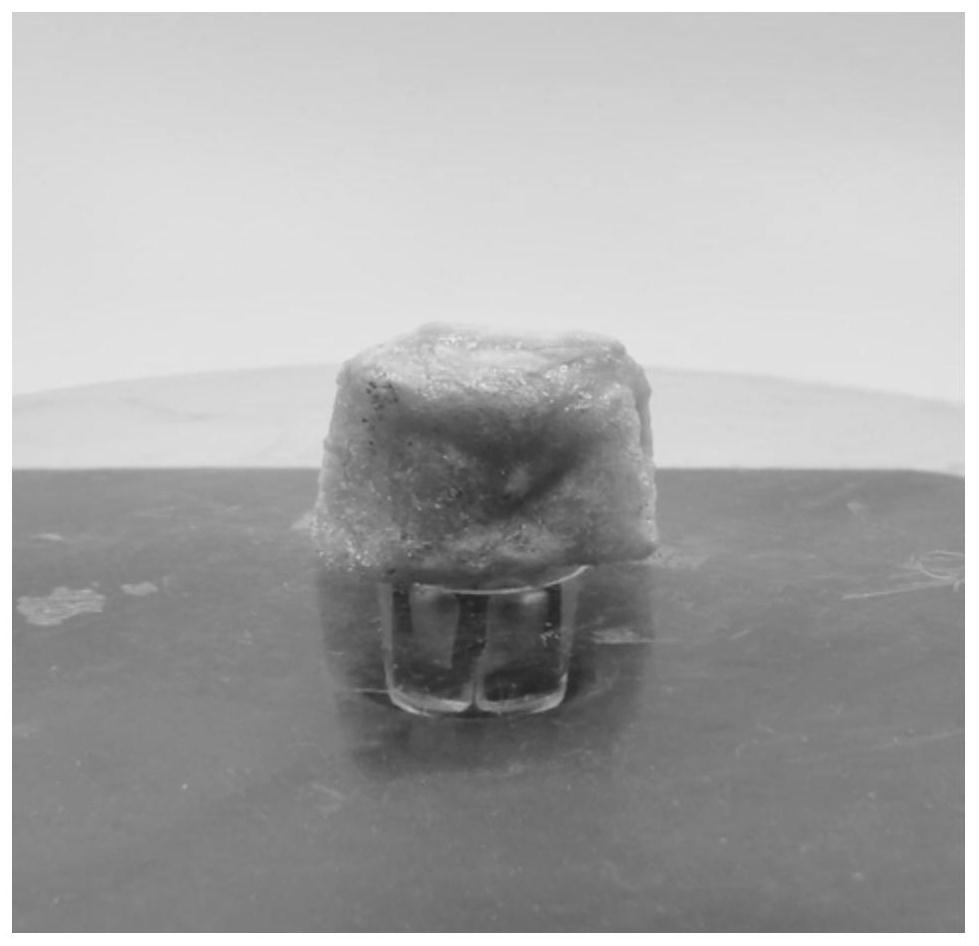

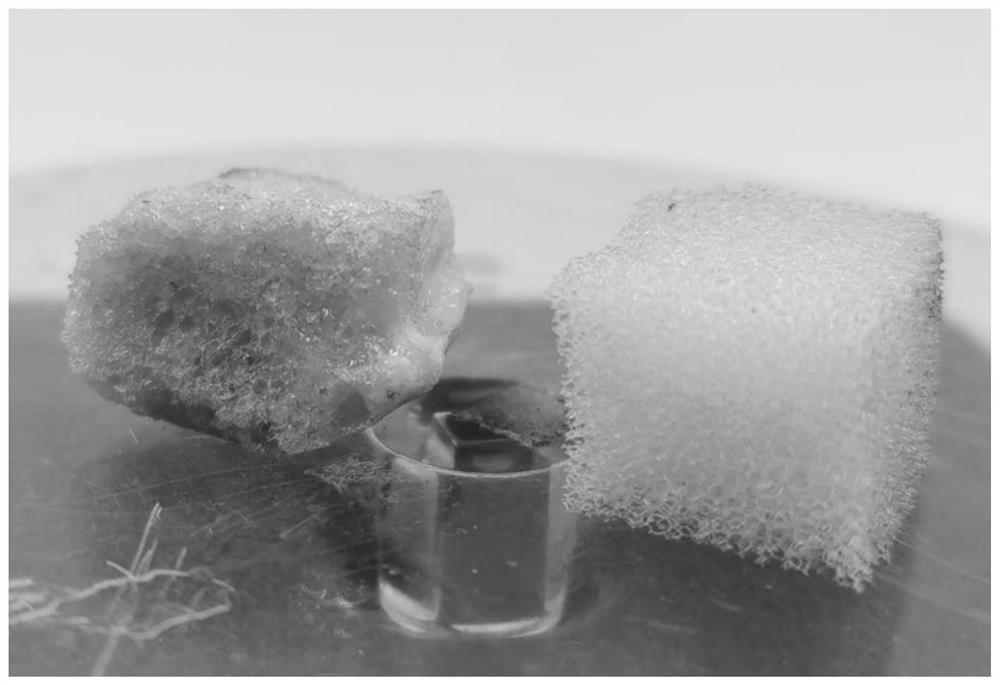

[0039] 2. Soak the sponge in the zwitterionic shape memory polymer solution for 10 minutes, then take out the sponge soaked in the shape memory polymer solution, such as figure 1Shown; placed in the air at room temperature for 10 minutes, let the excess solution flow out; then use freeze-drying equipment at -40 degrees Celsius for 36 hours to obtain the shape memory sponge; the dried sample (shape memory foam) and sponge raw material Comparison picture as figure 2 As shown, it is obvious that a large amount ...

Embodiment 2

[0041] 1. For the preparation method of hydrophilic shape memory polymer, please refer to the application number CN201580074457.X, which has authorized the invention patent Example 1 to prepare a hydrophilic shape memory polymer (TPEG 20); then the hydrophilic shape memory polymer The substance is heated and dissolved in water to obtain a shape memory polymer solution with a concentration of 40 wt %;

[0042] 2. Soak the sponge in the shape memory polymer solution for 5 minutes, then take out the sponge soaked in the shape memory polymer solution; place it in the air at room temperature for 5 minutes, let the excess solution flow out; and then process it with vacuum drying equipment at 50 degrees Celsius Within 24 hours, shape memory foam can be obtained;

[0043] 3. The dried sample (shape memory sponge) has a fluffy porous structure and a large volume, such as image 3 As shown; but under the condition of 50 degrees Celsius, for volume compression (a deformation method), th...

Embodiment 3

[0045] 1. For the preparation method of shape memory polymer, please refer to Example 1 of the authorized invention patent whose application number is CN201410357273.1, prepare a class of betaine type shape memory polymer (shape memory polymer based on DMAPS-AA), and then use the The shape memory polymer is dissolved in water to obtain a shape memory polymer solution with a concentration of 20 wt %;

[0046] 2. Soak the sponge in the shape memory polymer solution for 8 minutes, then take out the sponge soaked in the shape memory polymer solution; place it in the air at room temperature for 5 minutes, let the excess solution flow out; then use the freeze drying equipment at -40 degrees Celsius After processing for 36 hours, the shape memory foam can be obtained.

[0047] 3. After the shape memory sponge is compressed in volume at 50 degrees Celsius (a deformation treatment method), its shape can be fixed after volume compression at room temperature and under sealed conditions, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com