Electric pulse treatment method for improving defect or structure state of selective laser melting additive manufacturing titanium alloy

A technology of laser selective melting and additive manufacturing, which is applied in the field of electrical pulse processing to improve the defects or microstructure of titanium alloys by laser selective melting and additive manufacturing. Efficiency, significant organizational impact, defects, and the effect of improving organizational status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing.

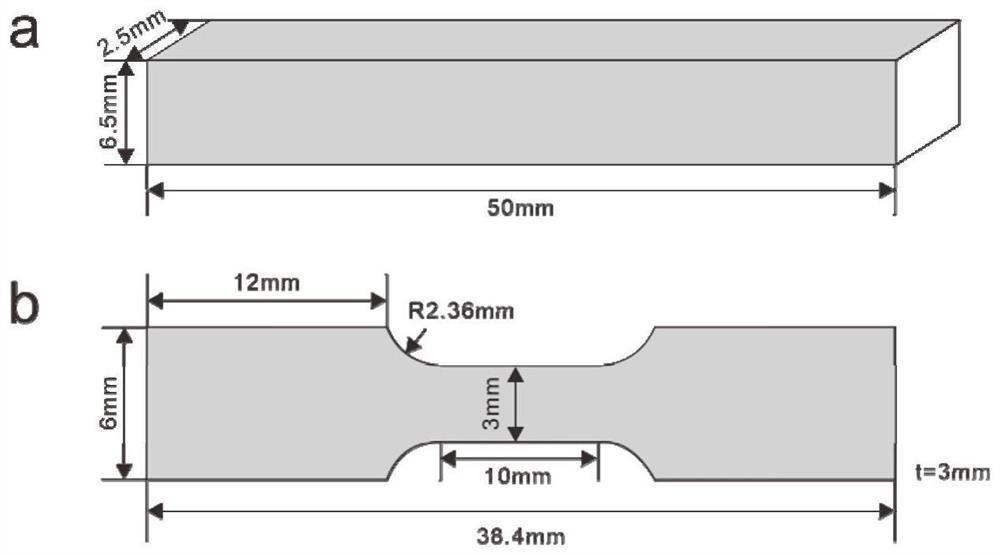

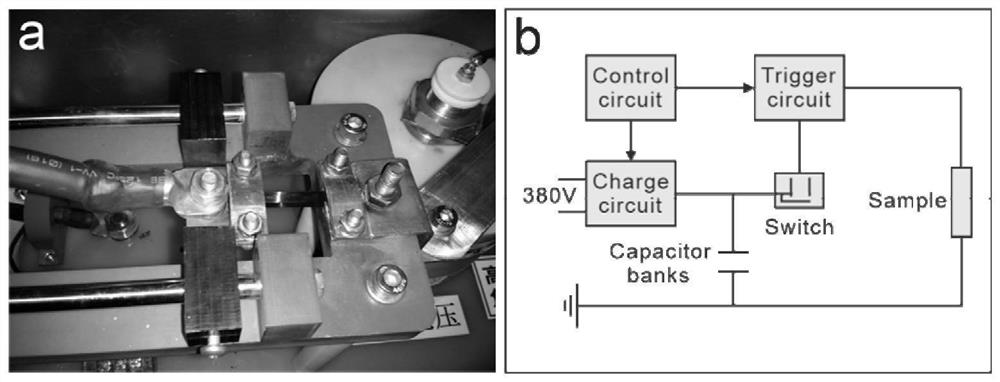

[0024] The present invention utilizes a high-energy pulse current device (for this device, refer to the relevant content in the patent with the application number 201811364353.4 and the invention title "An electric pulse processing device and method for reducing the fatigue crack growth rate of iron and steel materials"), using a single high-energy pulse The huge energy released by the current is manufactured by additively manufacturing titanium alloys ( figure 1 ) to improve its defects and organizational status. The electric pulse technology can be used for the research and application of the defect and structure optimization of additive manufacturing titanium alloy.

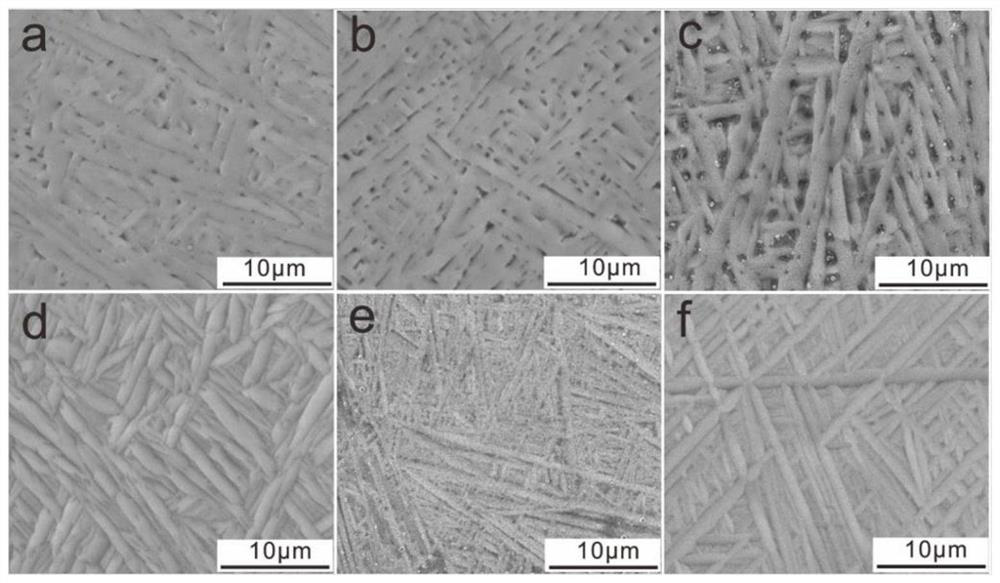

[0025] Using the above device to conduct electric pulse treatment on the Ti-6Al-4V titanium alloy sample for additive manufacturing, and compare and analyze the effect with the Ti-6Al-4V sample without electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com