Terminal electrolysis-resistant coating design method

A technology of electrolytic plating and design method, applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problem of failure to become a direction, and achieve the effect of outstanding electrolytic resistance and delaying electrolysis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

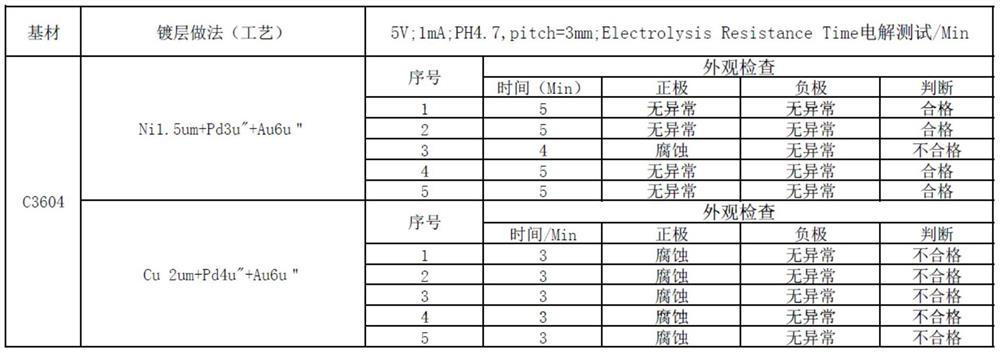

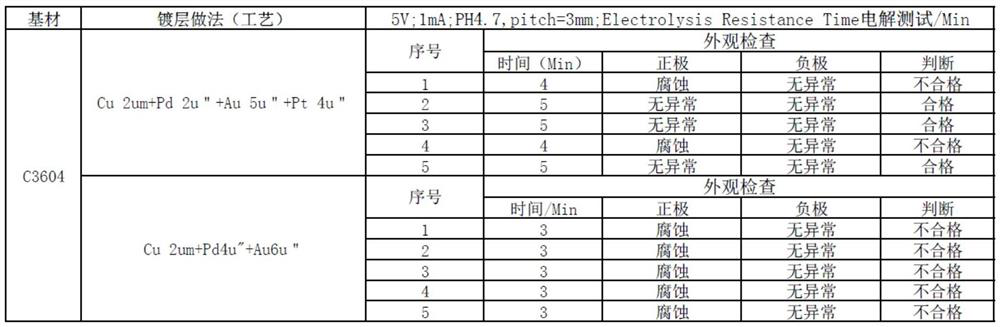

[0032] The specific embodiment of the present invention is introduced.

[0033] A terminal electrolytic plating resistant design method, comprising the following steps:

[0034] 1) Choose a non-passivated metal as the base material, and set a multi-layer combined coating on the base material to form an electrolysis-resistant whole; wherein, the hardness of the whole is greater than 168HV, the hardness of the base material is not less than 155HV, and the hardness of each coating is Not less than 120HV, and the hardness of the outermost coating is 400-1000HV;

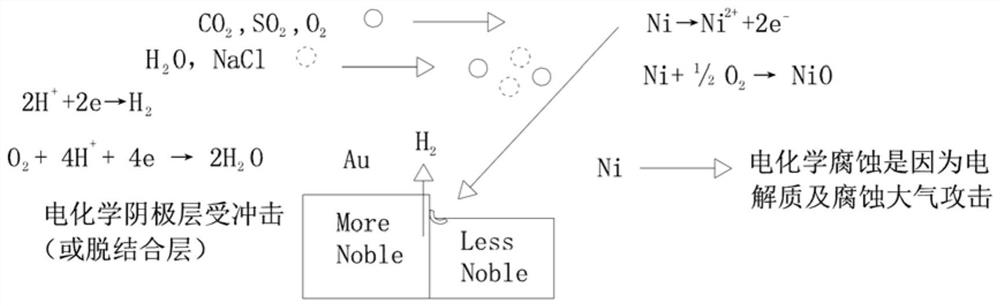

[0035] 2) Designing a coating sequence to improve the interlayer binding force of the combined coating, starting from the anodic phase coating on the base material, and sorting the coatings according to the positive and increasing standard potential of the metal electrode;

[0036] 3) Design the protective coating to protect the base material, and use the metal coating of the anode phase as the protective coating of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com