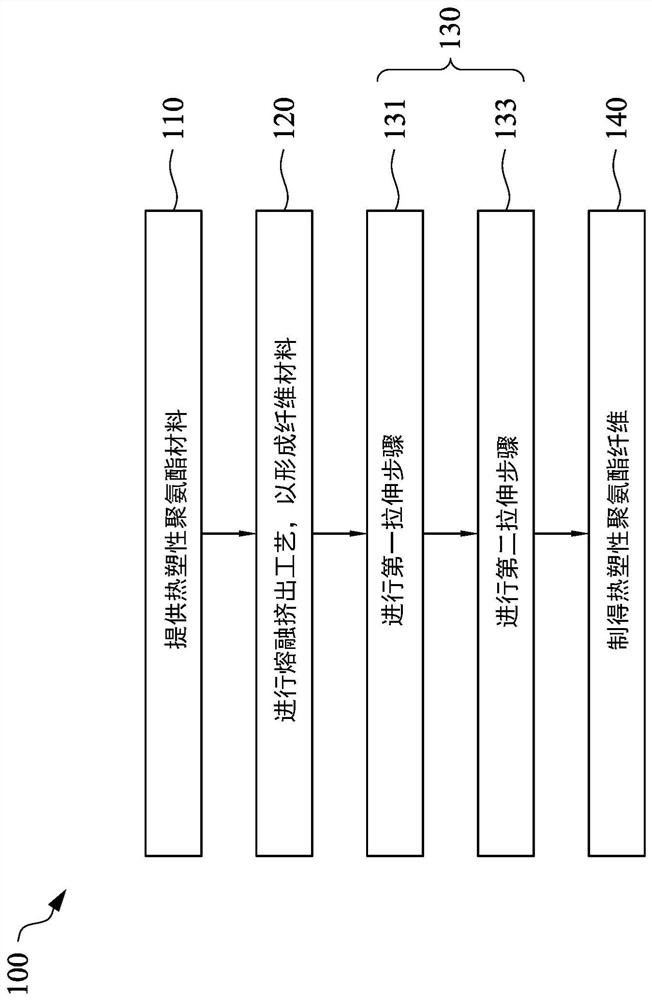

Thermoplastic polyurethane fiber and method for producing the same

A technology of thermoplastic polyurethane and its production method, which is applied in the field of thermoplastic polyurethane fiber, can solve the problems of reducing thermoplastic polyurethane fiber, not being able to balance heat shrinkability and recyclability, and reducing the recyclability of thermoplastic polyurethane materials, etc., achieving low heat shrinkage rate, good The effect of recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The thermoplastic polyurethane fiber of Example 1 is made of thermoplastic polyurethane elastomer (Shore D is 65D, and the melting point measured by DSC is 179.6° C.) produced by BASF. Then, the thermoplastic polyurethane elastomer system was placed in a drying barrel and dried at 80°C. After 6 hours, the moisture content of the thermoplastic polyurethane elastomer is less than 100ppm.

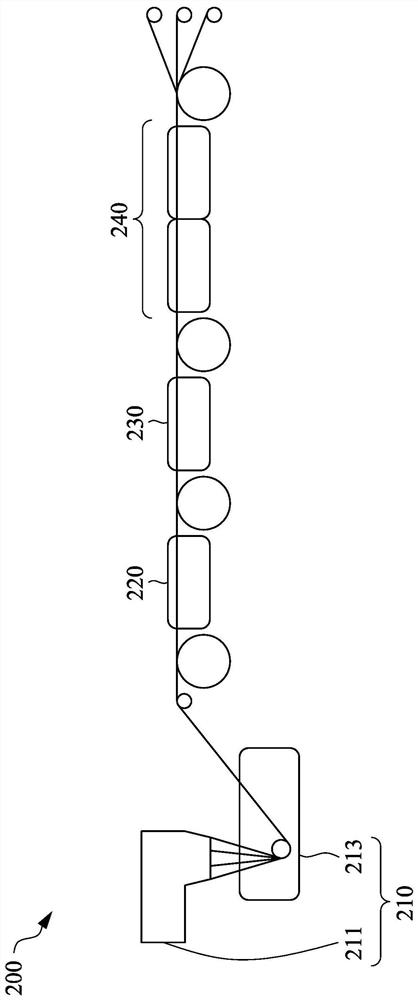

[0067] Next, the monofilament material of Example 1 was produced by a drawing system suitable for the monofilament material. Among them, the area from the feed inlet to the extrusion outlet of the melt spinning machine is divided into five sections, and the temperatures are respectively set at 180°C, 190°C, 200°C, 205°C and 205°C. The temperature of the cooling water tank was set to 25°C.

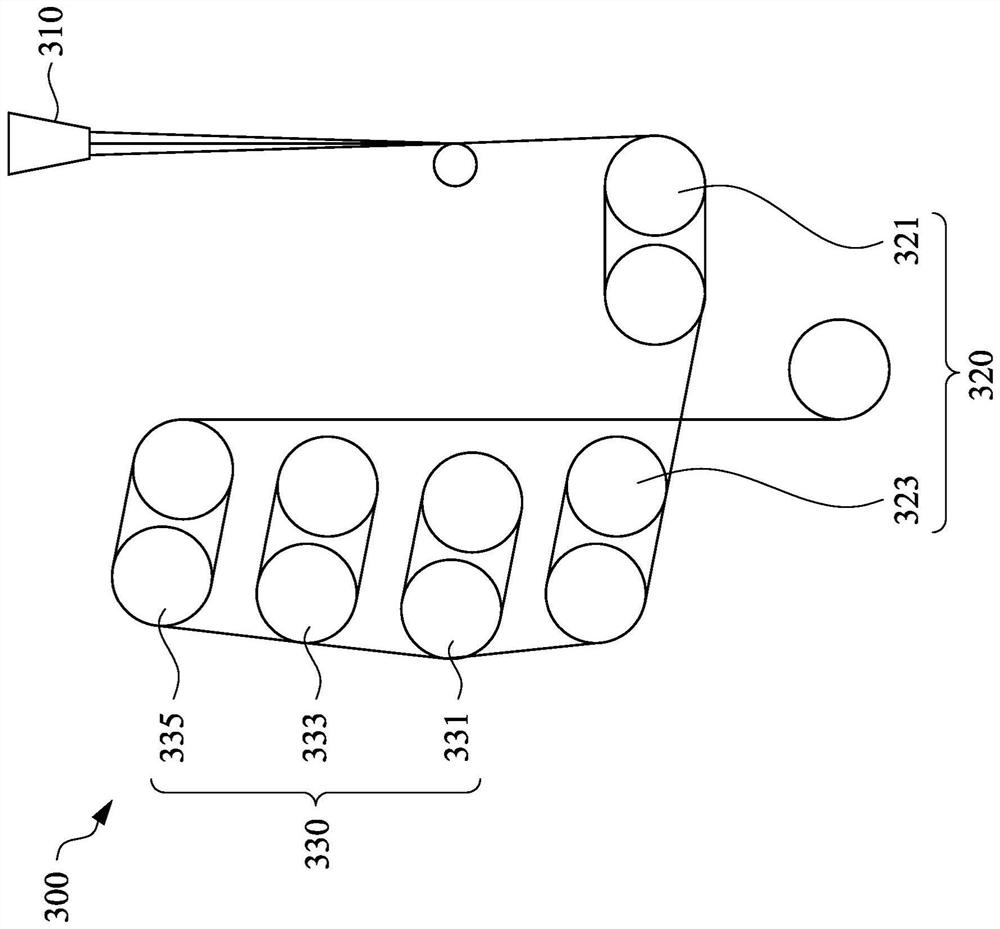

[0068] Then, the cooled monofilament material was subjected to a first drawing step, wherein the temperature of the hot water bath was 80° C., and the drawing ratio of the first drawing step was 4....

Embodiment 2

[0071] The thermoplastic polyurethane fiber of Example 2 is made by using thermoplastic polyurethane elastomer (Shore D is 65D, and the melting point measured by DSC is 179.6° C.) produced by BASF. Then, the thermoplastic polyurethane elastomer system was placed in a drying barrel and dried at 80°C. After 6 hours, the moisture content of the thermoplastic polyurethane elastomer is less than 100ppm.

[0072] Next, the monofilament material of Example 2 was produced by a drawing system suitable for the monofilament material. Among them, the area from the feed inlet to the extrusion outlet of the melt spinning machine is divided into five sections, and the temperatures are respectively set at 180°C, 190°C, 200°C, 205°C and 205°C. The temperature of the cooling water tank was set to 25°C.

[0073] Then, the cooled monofilament material was subjected to a first drawing step, wherein the temperature of the hot water bath was 80° C., and the drawing ratio of the first drawing step ...

Embodiment 3

[0075] Embodiment 3, comparative example 1 and comparative example 2

[0076]Embodiment 3, comparative example 1 and comparative example 2 use the same preparation method and evaluation method as the preparation method of the thermoplastic polyurethane fiber of embodiment 2, and the difference is that embodiment 3, comparative example 1 and comparative example 2 use different The raw materials or stretching parameters are used to make thermoplastic polyurethane fibers. The formula and evaluation results are shown in Table 1, and will not be described here.

[0077] Table 1

[0078]

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com