Variable pre-taper angle device for wind wheel of wind turbine generator and use method

A technology of wind turbines and pre-cone angles, which is applied to wind turbines, wind power generation, wind turbines, etc. in the same direction as the wind. It can solve problems such as reducing power generation, tower collisions, and blade deformation, and achieve reduced maintenance costs. The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

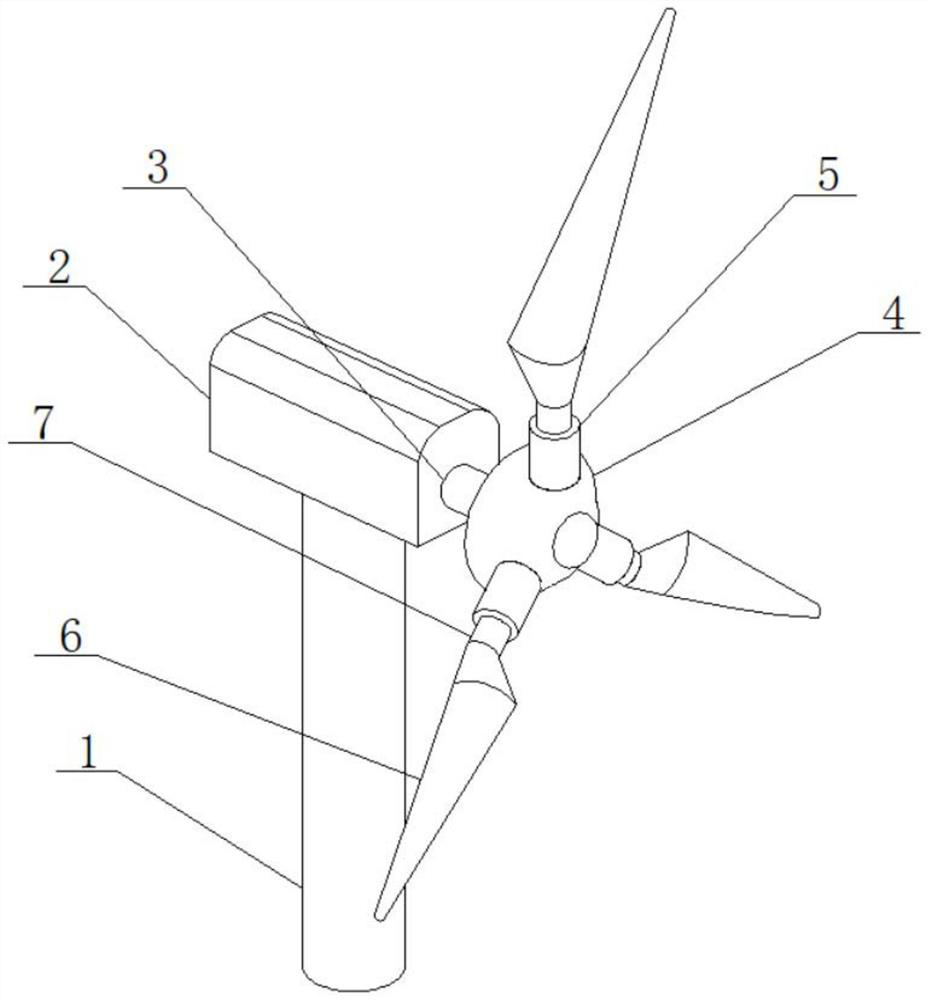

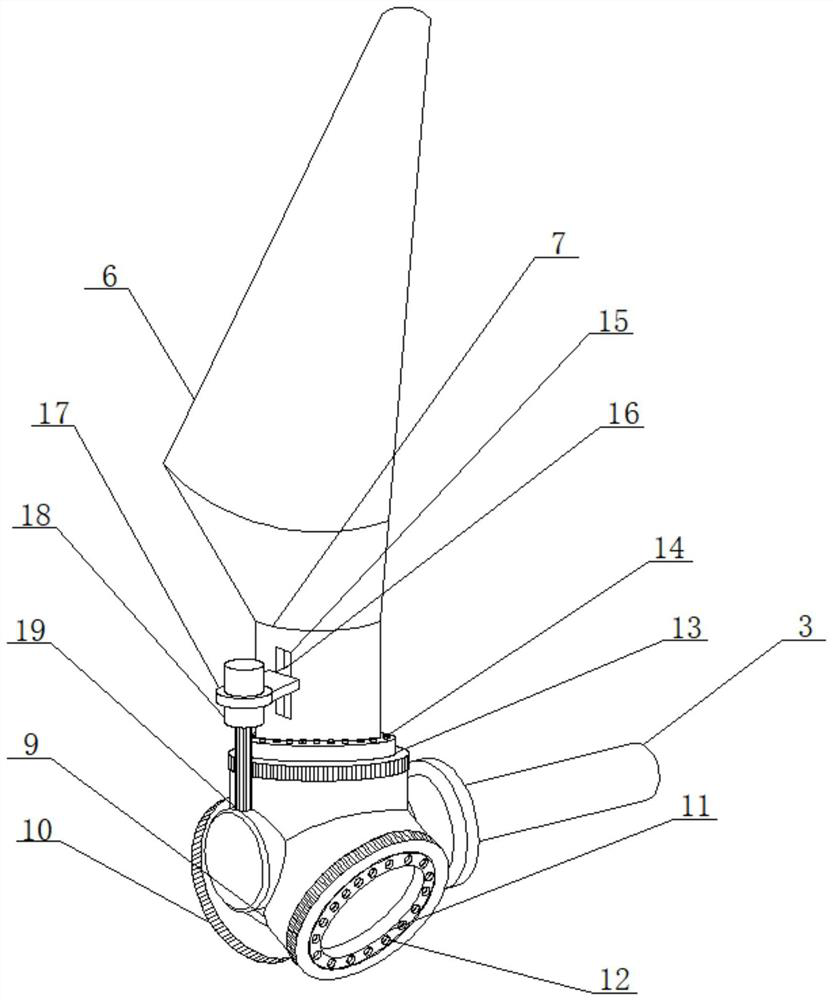

[0037] see Figure 1 to Figure 7 , the present invention provides a variable pre-cone angle device for a wind turbine of a wind turbine, comprising a tower 1, a nacelle 2 is installed on the top of the tower 1, a main shaft 3 is installed on the nacelle 2, and a connecting seat 9 is connected to the other end of the main shaft 3 The hub 4 is installed on the outside of the connecting seat 9, the hub 4 is connected with the blade root connection section 5, the blade root connection section 5 is connected with the blade root 7, and the blade root 7 is connected with the blade 6.

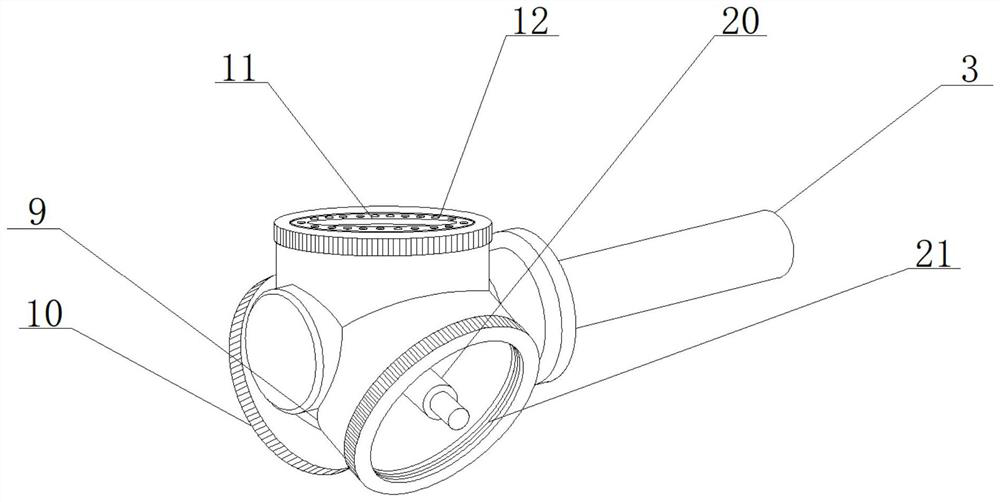

[0038] The connecting seat 9 is arranged in a Y shape, including three protrusions 91; the three protrusions 91 are evenly arranged, and the angle between them is 120°. The top of the boss 91 is provided with a gear ring 10, and the inner wall of the gear ring 10 is provided with a fixing groove 21, through which the pitch bearing 11 is installed in the gear ring 10, and the pitch bearing 11 is provide...

Embodiment 2

[0046] The present invention also provides a method for using a variable pre-cone angle device for a wind turbine rotor, comprising the following steps:

[0047] Step 1: Use the power supply after power generation to provide the required electric energy to the internal electrical appliances. After the installation of each device is completed, the blades 6 are rotated by the blowing of wind energy, and the rotation of the blades 6 causes the hub 4 and the main shaft 3 to rotate. , so that the main shaft 3 converts the kinetic energy transmission into electric energy for use.

[0048] Step 2: Adjust the pre-cone angle of the blade 6 according to different situations. When in use, according to the different wind directions, the motor 18 drives the toothed roller 19 to rotate. The moving blade root 7 makes the blade 6 rotate on the pitch bearing 11 through the fixed disk 13 to adjust the angle; the pitch bearing 11 rotates inside the fixed groove 21 through the fixed rod 23 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com