MFC toxicity sensor and application thereof

A sensor and toxicity technology, applied in the field of MFC toxicity sensors, can solve the problems of inability to recover energy and stably treat electroplating wastewater, unable to meet real-time monitoring of water bodies, timely feedback data, and limit the application of detection methods, etc. Monitoring, convenient and timely transmission of information, and the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

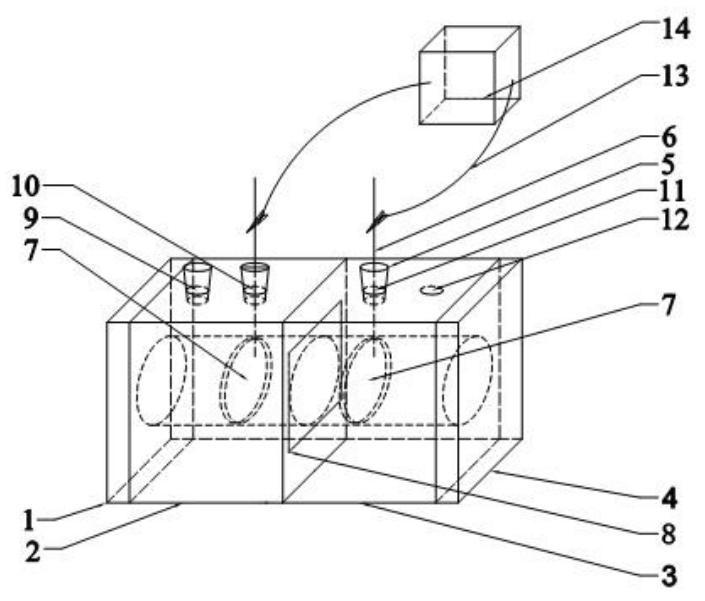

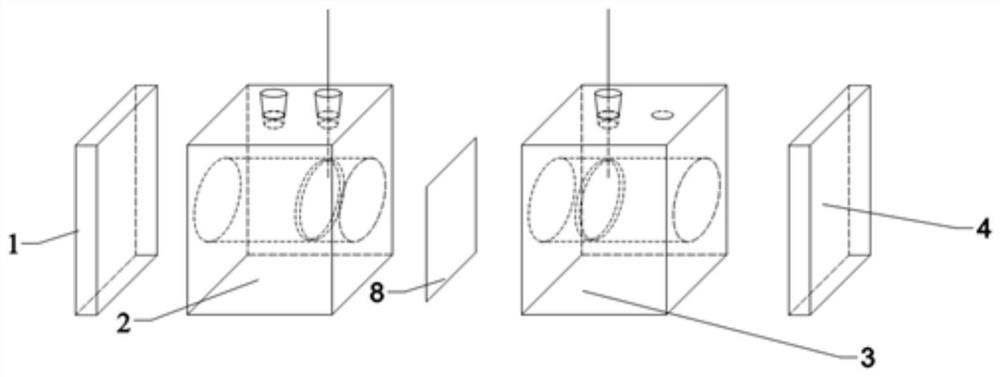

[0038] The MFC toxicity sensor of this embodiment is divided into two parts: a main body and an external circuit. The main body includes a first acrylic component 1, a second acrylic component 2, a third acrylic component 3 and a fourth acrylic component 4 connected in sequence. The first acrylic member 1 has the same structure as the fourth acrylic member 4, the first acrylic member 1 and the fourth acrylic member 4 are cuboids with a length of 1 cm, a width of 8 cm and a height of 8 cm; The structure of the third acrylic member 3 is the same. The outside is a cuboid with a length of 6.8cm, a width of 8cm and a height of 8cm. The corners of -4 are provided with through holes ( figure 1 and figure 2 Not shown in ) for long screw fixing members 1-4; the middle of the second member 2 and the third member 3 is hollowed out as a cylinder. In order to ensure that the cylindrical chambers of the second member 2 and the third member 3 can form a closed space for storing cathode an...

Embodiment 2

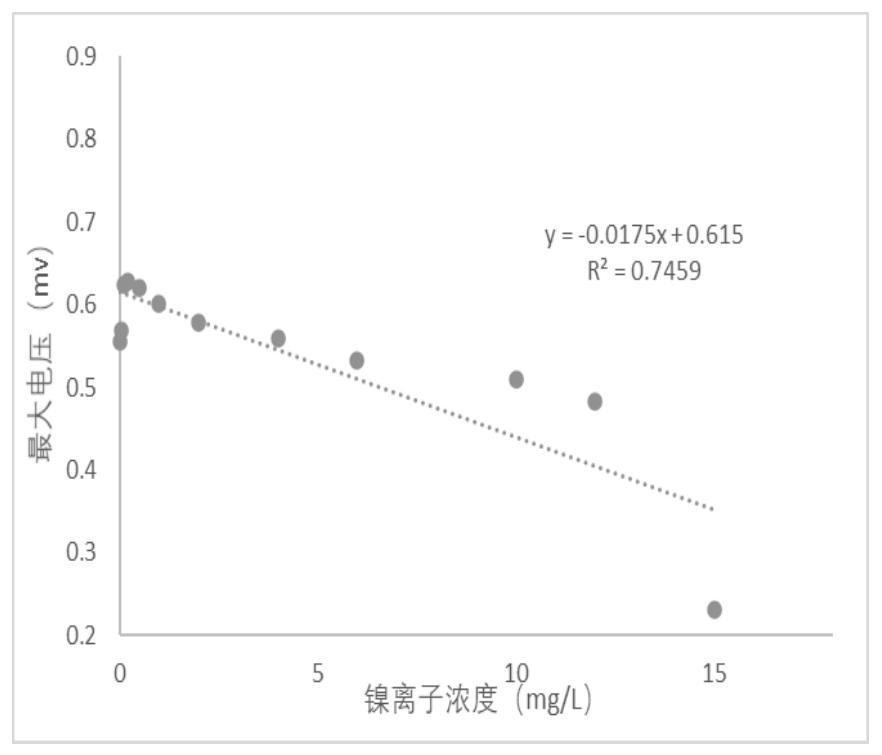

[0059] The MFC toxicity sensor adopted in this embodiment has the same structure as that in Embodiment 1, and detects the influent containing only nickel ions (denoted as MFC1), and the influent containing four heavy metal ions of nickel, copper, zinc, and cadmium. Fix the influent concentration of three kinds of heavy metal ions, change the influent concentration of nickel ions (denoted as MFC2), change the influent concentration of three kinds of heavy metal ions, fix the influent concentration of nickel ions (denoted as MFC3). The specific heavy metal concentration gradient details are shown in Table 3.

[0060] Table 3 Concentration gradient of heavy metals

[0061]

[0062]

[0063] Table 4 shows the maximum electricity production results of each concentration gradient of MFC1, MFC2 and MFC3.

[0064] Table 4 Maximum power generation

[0065]

[0066]

[0067] Draw a graph with the concentration gradient as the abscissa and the maximum output voltage of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com