Screening method of corrosion inhibitor for aluminum foil etching based on molecular modeling

A screening method and molecular modeling technology, which is applied in the field of screening corrosion inhibitors for aluminum foil etching, can solve the problems of complex process, low reliability, and low research and development efficiency, so as to reduce research and development costs, optimize design, and improve performance evaluation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

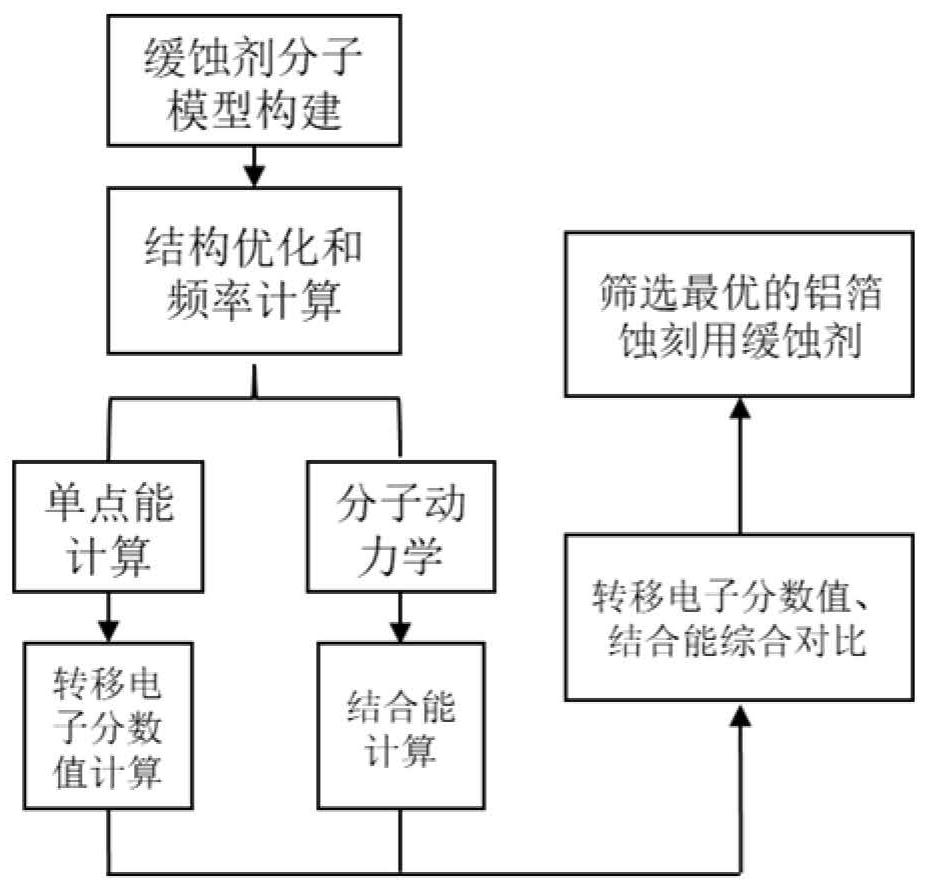

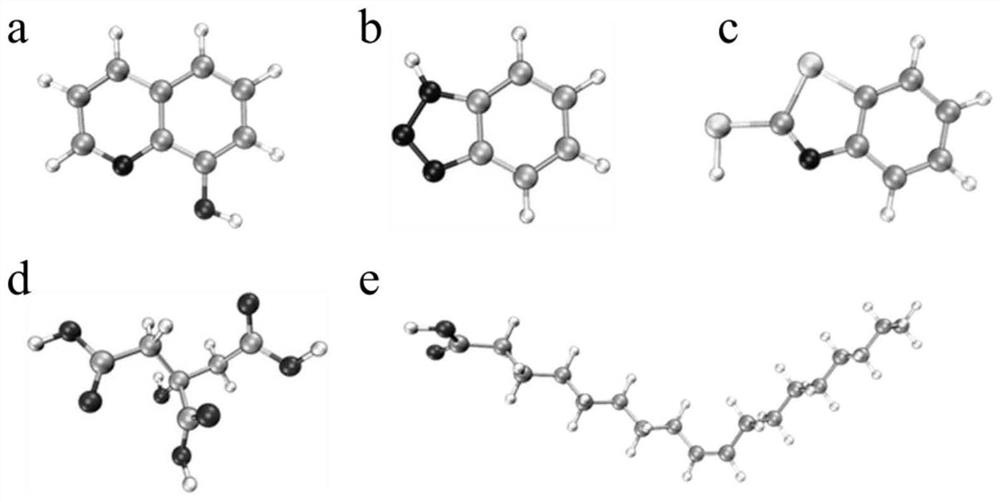

[0061] 1. Based on the GaussView modeling software, the molecular models of five corrosion inhibitors, 8-hydroxyquinoline, benzotriazole, mercaptobenzothiazole, citric acid and oleic acid, were constructed, respectively the first, second and second 3rd, 4th and 5th corrosion inhibitors.

[0062] 2. Based on the Gaussian calculation software, select the calculation type as structural optimization and frequency calculation, and set the water solvent conditions in the SMD model to study the geometric structure characteristics of the above five corrosion inhibitor molecules in solution. The calculation method is B3LYP at the DFT level Methods: 6-31G(d) was selected as the basis set, and the structure optimization and frequency calculation of the molecular models of the above five corrosion inhibitors were carried out respectively.

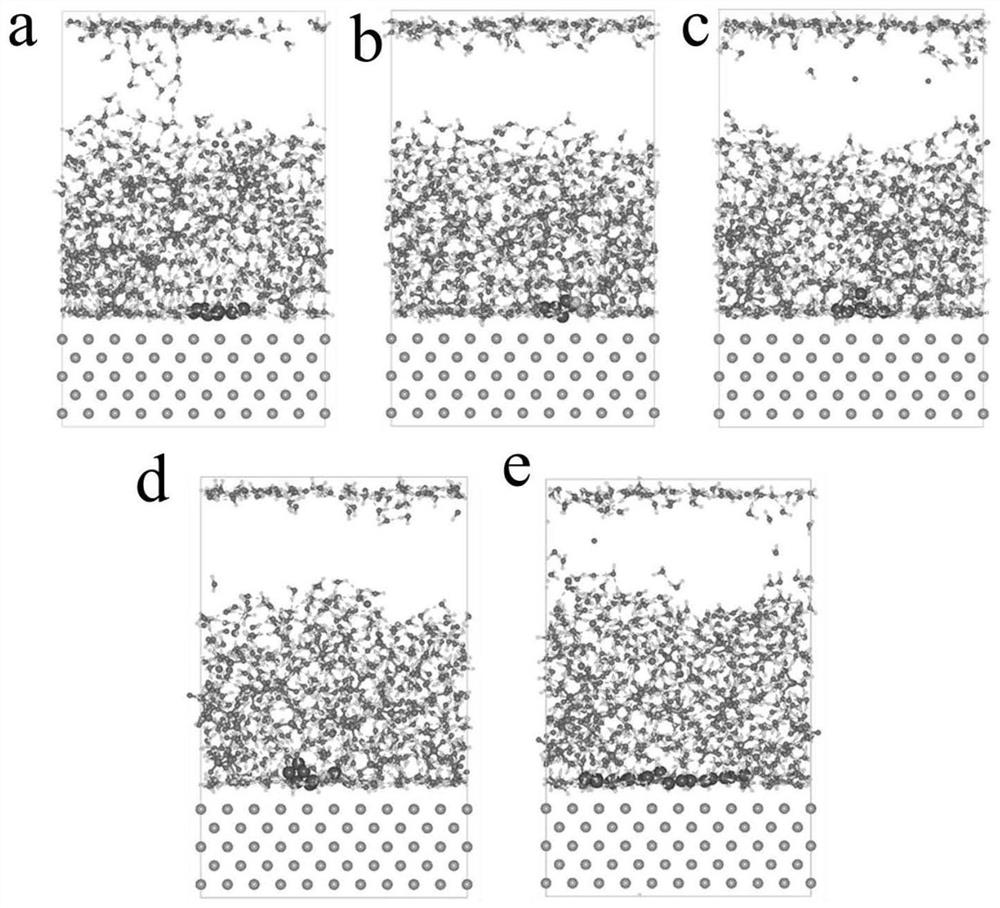

[0063] 3. For the optimized corrosion inhibitor molecular model, import the Gaussian calculation program, select the calculation type as energy calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com