Stabilizing agent composition, vinyl chloride resin composition containing same and molded body thereof

A technology of vinyl chloride resin and composition, applied in the direction of composition, chemical instrument and method for inhibiting chemical change, can solve problems such as decomposition and insufficient stability, and achieve the effects of excellent transparency and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

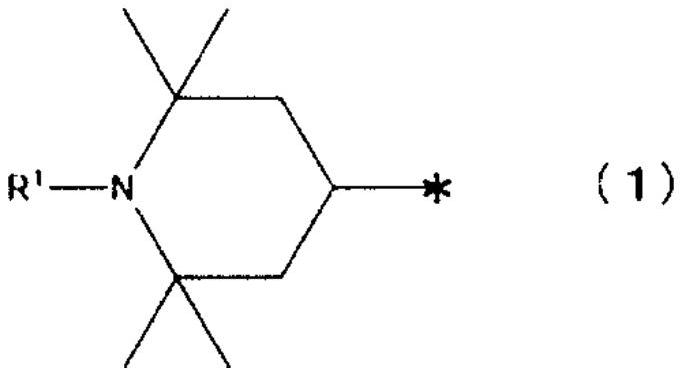

Method used

Image

Examples

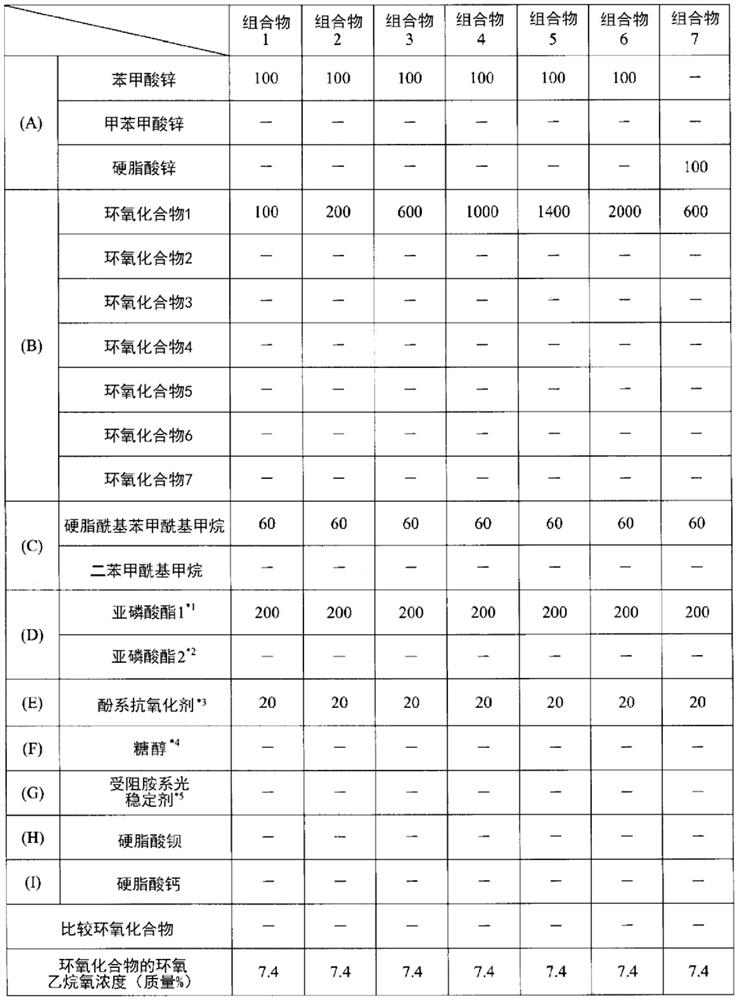

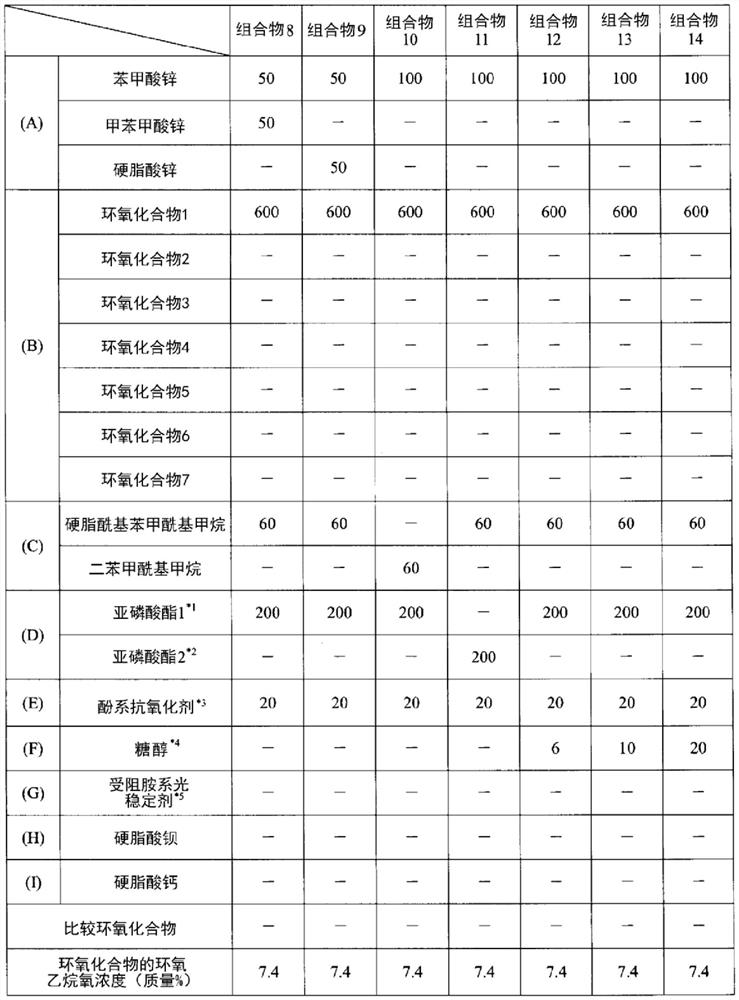

Embodiment 1~84 and comparative example 1~10

[0168] According to the proportions shown in Tables 13 to 27, the vinyl chloride resin, the composition and other additives were blended with a Henschel mixer to obtain each vinyl chloride resin composition. The obtained vinyl chloride resin composition was calender-molded to produce a sheet. The roll kneading conditions were 165° C.×30 rpm×0.6 mm. Using the obtained sheet, dynamic heat stability, static heat stability, coloring resistance, heat coloring resistance, and transparency were evaluated by the following test methods. The evaluation results are collectively described in Tables 13-27.

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com