Method and device for continuously preparing high-quality PBAT

A high-quality, catalyst technology, applied in the field of continuous preparation of high-quality PBAT, can solve the problems of high acid value and melt index, wide relative molecular weight distribution, difficult to control, poor color and so on, achieve low acid value and melt index, relative molecular weight distribution. Narrow, improve the effect of color defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

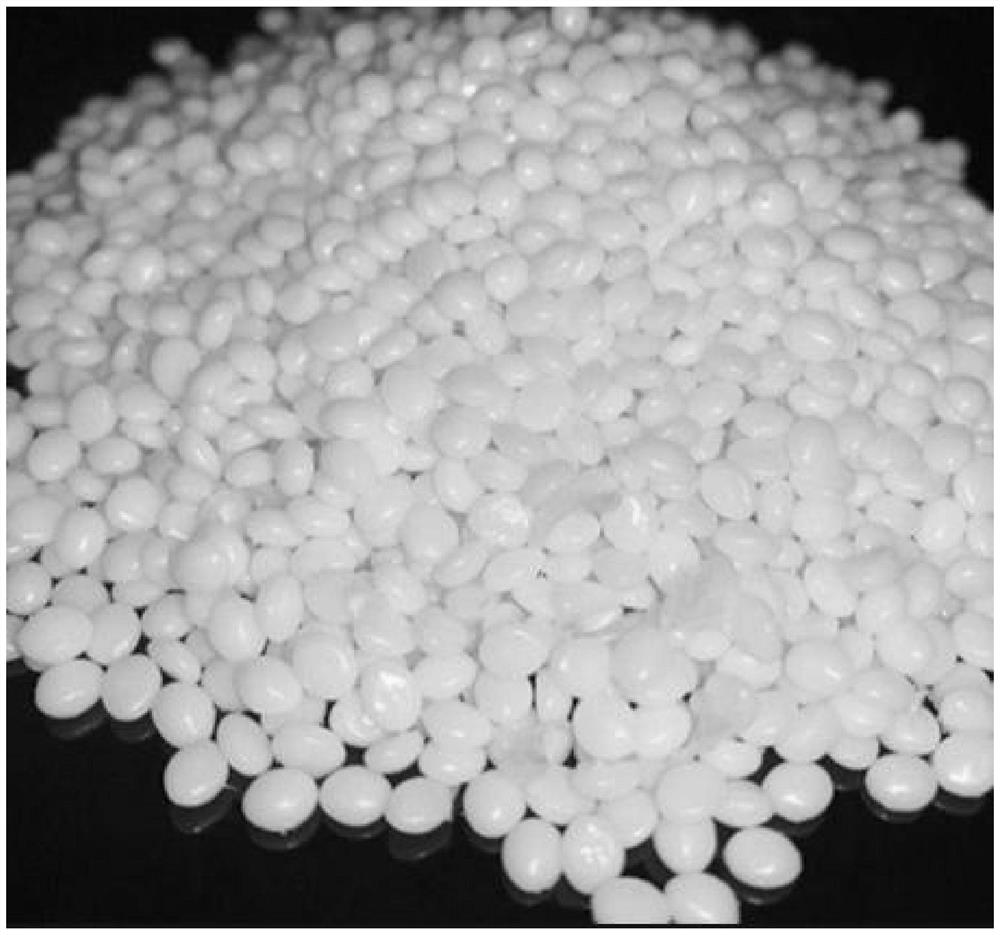

[0055] Add the PTA / BDO and AA / BDO slurries to the first esterification tank respectively, add 0.3wt% catalyst, carry out the esterification reaction at 195°C and 160°C respectively, and then put the esterified product in the first esterification tank Transfer to the second esterification tank, add 0.3wt% catalyst, and the esterification rate reaches more than 98% at this time, then transfer the esterified product in the second esterification tank to the polycondensation reactor, add 0.15wt% catalyst, 1wt% stabilizer UV-944 and tris (2,4-di-tert-butylphenyl) phosphite (mass ratio 1:4), and reacted at 250 ° C for 90 minutes, and the PBAT melt obtained by polycondensation reaction was transported to Viscosification reactor is used to increase viscosity to obtain high molecular weight PBAT melt, and finally PBAT melt enters pelletizing system to obtain PBAT resin.

Embodiment 2

[0057] PTA / BDO and AA / BDO slurries were added to the first esterification tank, 0.4wt% catalyst was added, and the esterification reaction was carried out at 195°C and 160°C respectively, and the esterified product in the first esterification tank was Transport to the second esterification tank, add 0.25wt% catalyst, and the esterification rate reaches more than 98% at this time, then transport the esterified product in the second esterification tank to the polycondensation reactor, add 0.2wt% catalyst, 1.5wt% % stabilizer UV-770 and tris (2,4-di-tert-butylphenyl) phosphite (mass ratio is 1:3), and reacted at 250°C for 90 minutes, and the PBAT melt obtained by polycondensation reaction was transported Go to the thickening reaction kettle for thickening to obtain high molecular weight PBAT melt, and finally the PBAT melt enters the pelletizing system to obtain PBAT resin.

Embodiment 3

[0059] PTA / BDO and AA / BDO slurries were added to the first esterification tank, 0.4wt% catalyst was added, and the esterification reaction was carried out at 195°C and 160°C respectively, and the esterified product in the first esterification tank was Transport to the second esterification tank, add 0.2wt% catalyst, and the esterification rate reaches more than 98% at this time, then transport the esterified product in the second esterification tank to the polycondensation reactor, add 0.2wt% catalyst, 0.8wt% % stabilizer UV-119FD and bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite (mass ratio is 2:1), and reacted at 250°C for 90min, the PBAT melt obtained through polycondensation The body is transported to the thickening reactor for thickening to obtain high molecular weight PBAT melt, and finally the PBAT melt enters the pelletizing system to obtain PBAT resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com