Anti-halation glass assembly with ultrahigh cathode sensitivity as well as preparation method and application of anti-halation glass assembly

A sensitivity and glass technology, applied in the field of anti-halation glass components and its preparation, to achieve the effect of improving cathode sensitivity, environmental protection cost, and high optical transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

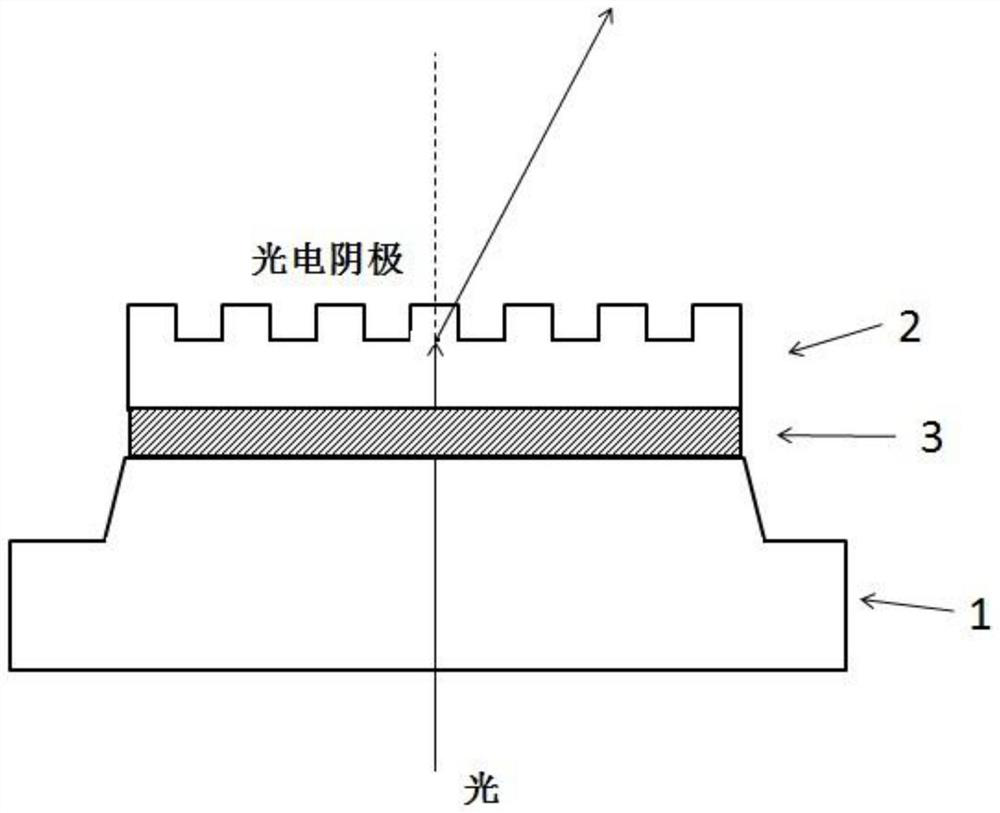

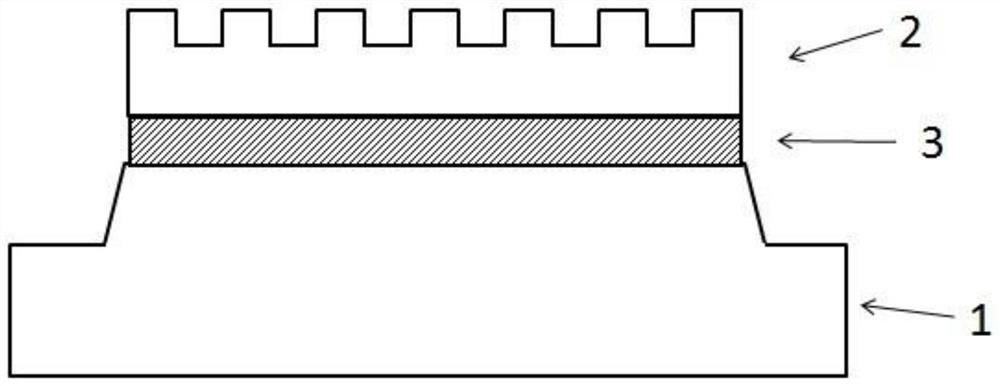

[0042] The present invention also provides a method for preparing an anti-halation glass assembly with ultra-high cathode sensitivity, comprising the following steps:

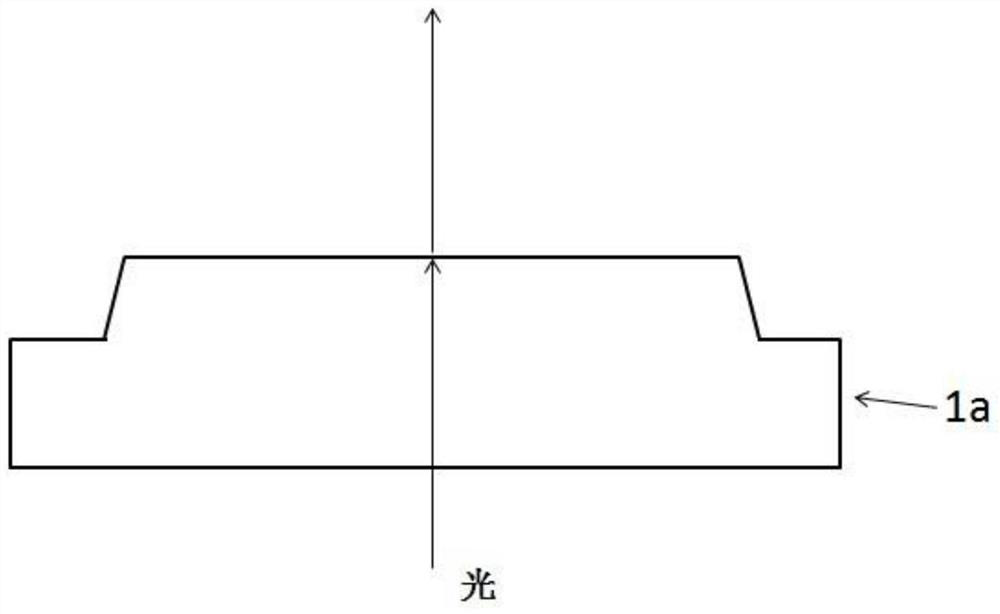

[0043] S1 Prepare the above-mentioned anti-halation step substrate glass 1 and the second thin glass sheet 2 through the prior art;

[0044] S2 Prepare the first thin glass sheet 3, and then thermally bond the anti-halation step substrate glass 1 and the second thin glass sheet 2 (in a vacuum heating furnace, the bonding temperature is controlled at 600-650°C between) connected as one.

[0045] The preparation method of the first thin glass sheet 3 comprises the following steps:

[0046] 1) Weigh SiO according to mole percentage (mol%) 2 , 55-65%; B 2 o 3 , 20-25%; Na 2 O, 3-5%; K 2 O, 1-2%; Al 2 o 3 , 3-4%; LiF, 3-5%; ZnO, 1-6%, mixed evenly to obtain batch materials;

[0047] 2) At 1400-1480°C, add the batch material to the crucible for melting for several times, and the interval between each additio...

Embodiment 1

[0054] This embodiment provides an anti-halation glass assembly with ultra-high cathode sensitivity, the anti-halation glass assembly is composed of anti-halation stepped substrate glass 1 (with opposite small faces and large faces, the small The surface diameter is 21mm), the first thin glass sheet 3 and the second thin glass sheet 2, the surface of the second thin glass sheet 2 is provided with a micro-nano array structure. The anti-halation step substrate glass 1 and the second thin glass sheet 2 are selected from the prior art, which are the same high borosilicate glass, and the transition temperature T of the high borosilicate glass is g 550℃, softening point temperature T f 658°C, the coefficient of thermal expansion at 20°C-300°C is 52×10 -7 / °C, the optical refractive index is 1.490; the material of the first thin glass sheet 3 is SiO 2 -B 2 o 3 -ZnO glass, the SiO 2 -B 2 o 3 -The softening point temperature T of ZnO glass f is 600°C; the SiO 2 -B 2 o 3 -T...

Embodiment 2

[0069] This embodiment provides an anti-halation glass assembly with ultra-high cathode sensitivity, the anti-halation glass assembly is composed of anti-halation stepped substrate glass 1 (with opposite small faces and large faces, the small The diameter of the surface is 22mm), the first thin glass sheet 3 and the second thin glass sheet 2, and the surface of the second thin glass sheet 2 is provided with a micro-nano array structure. The anti-halation step substrate glass 1 and the second thin glass sheet 2 are selected from the prior art, which are the same high borosilicate glass, and the transition temperature T of the high borosilicate glass is g 560℃, softening point temperature T f 650°C, the coefficient of thermal expansion at 20°C-300°C is 54×10 -7 / °C, the optical refractive index is 1.500; the material of the first thin glass sheet 3 is SiO 2 -B 2 o 3 -ZnO glass, the SiO 2 -B 2 o 3 -The softening point temperature T of ZnO glass f is 592°C; the SiO 2 -B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transition temperature | aaaaa | aaaaa |

| Softening point temperature | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com