A downhole preheating and start-up method for super heavy oil reservoirs developed by dual horizontal well sagd

A dual-horizontal well and ultra-heavy oil technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve problems such as high cost and high price of solvents, reduce heat loss, avoid coking problems, The effect of improving heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

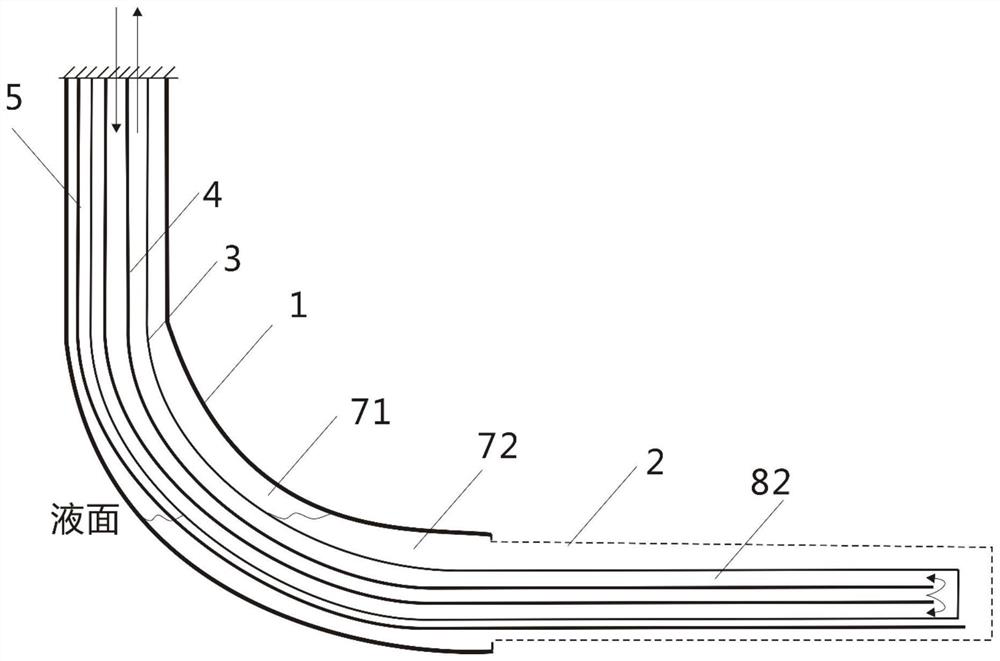

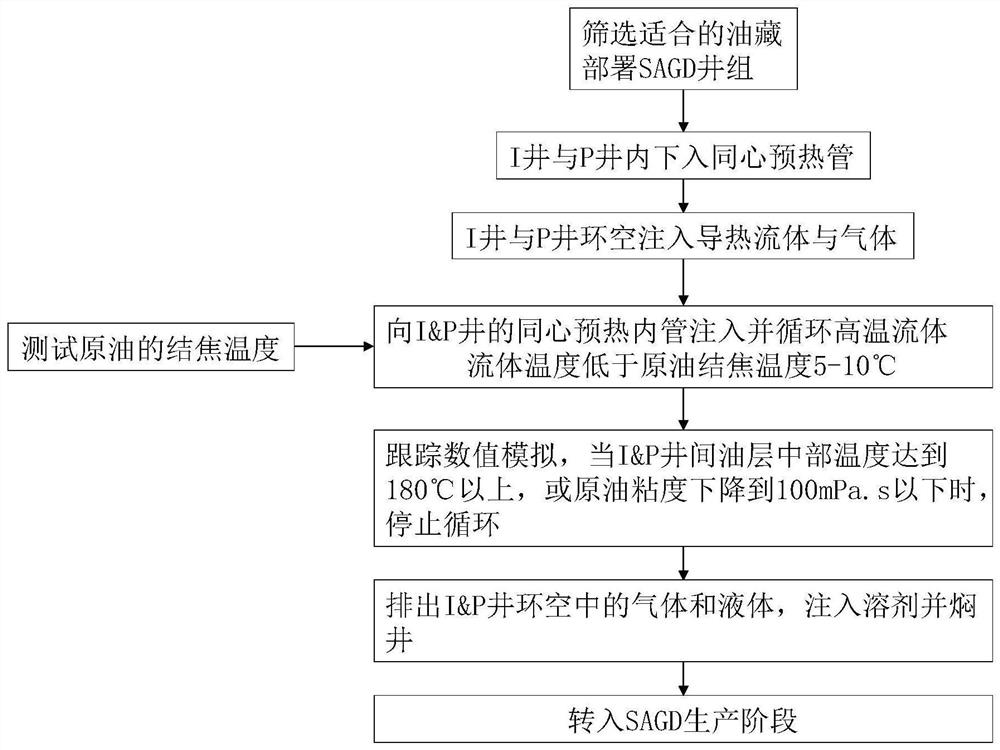

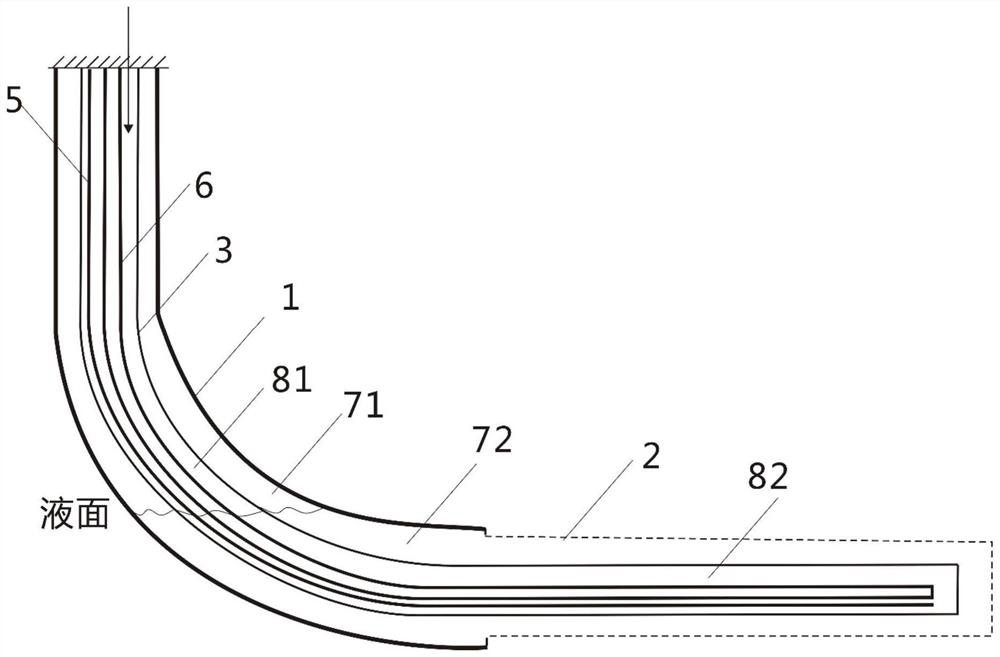

Method used

Image

Examples

Embodiment 1

[0085] (5) Measure the initial coking temperature of the crude oil in the oil layer, and determine the temperature 320°C corresponding to the coking rate of different crude oils.

[0088] (7) By establishing a well group numerical model, the inter-well temperature rise tracking prediction is performed, thereby determining the temperature in the middle of the oil layer. establish

Embodiment 2

[0100] (5) Measure the initial coking temperature of the crude oil in the oil layer, and determine the temperature 350°C corresponding to different crude oil coking rates.

[0103] (7) By establishing a numerical model of the well group, the inter-well temperature rise tracking prediction is performed, thereby determining the temperature in the middle of the oil layer. establish

Embodiment 3

[0115] (5) Measure the initial coking temperature of the crude oil in the oil layer, and determine the temperature 340°C corresponding to different crude oil coking rates.

[0118] (7) By establishing a well group numerical model, the inter-well temperature rise tracking prediction is performed, thereby determining the temperature in the middle of the oil layer. establish

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com