Intelligent reversible photosensitive femtosecond laser photoresist and photoetching processing method

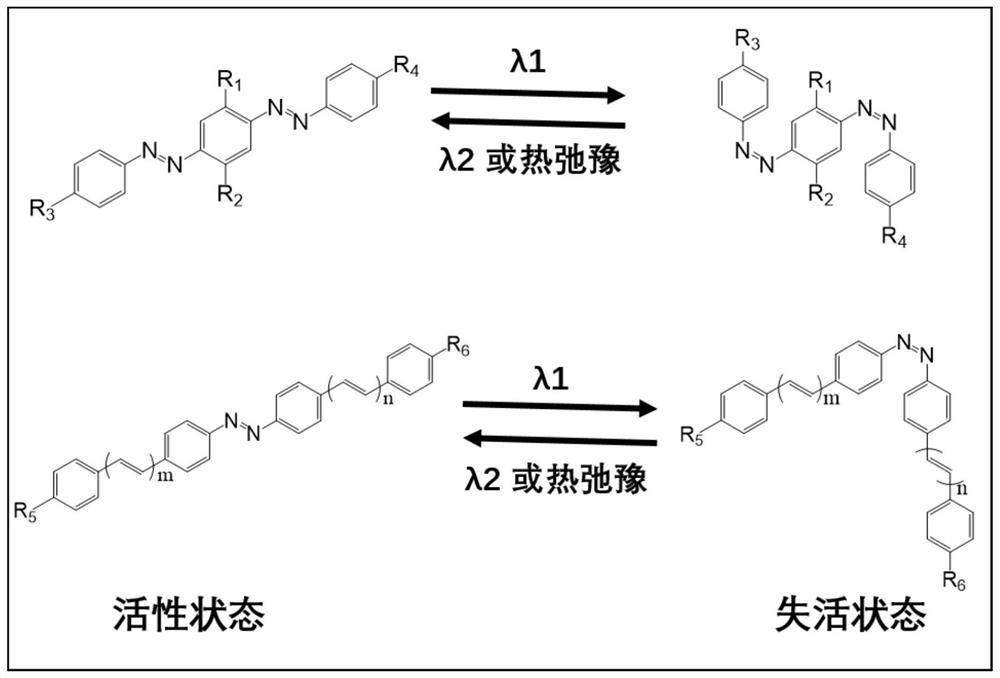

A technology of femtosecond laser and lithography processing, which is applied in the direction of optics, optomechanical equipment, photoplate making process of pattern surface, etc., can solve the problems of unstable suppression effect, etc., and achieve sensitivity improvement, high nonlinear absorption capacity, high The effect of photolithographic precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the yellow light chamber, mix and stir the reversible photoinitiator A-1 and resin B-1 according to the ratio of experiment 1 and experiment 2 in the following table 1; after filtering out impurities with a filter membrane, an intelligent reversible photosensitive femtosecond laser light is obtained. Engraving.

[0043](1) Take the intelligent femtosecond laser photoresist composition and drop it on a 2-inch silicon wafer, and use a homogenizer to spin-coat to prepare a photoresist film. The homogenization process adopts a programmed speed increase, specifically: 100 rpm for 10 s, 500 rpm for 10 s, and 1500 rpm for 60 s.

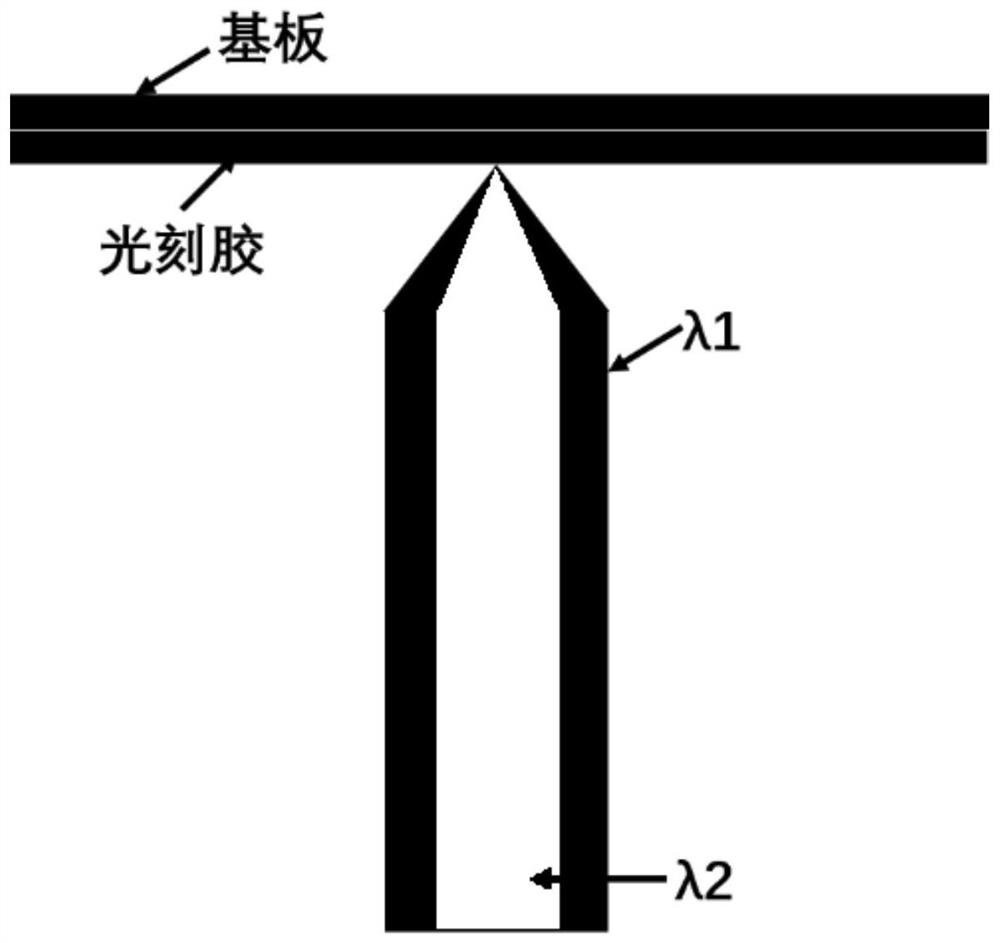

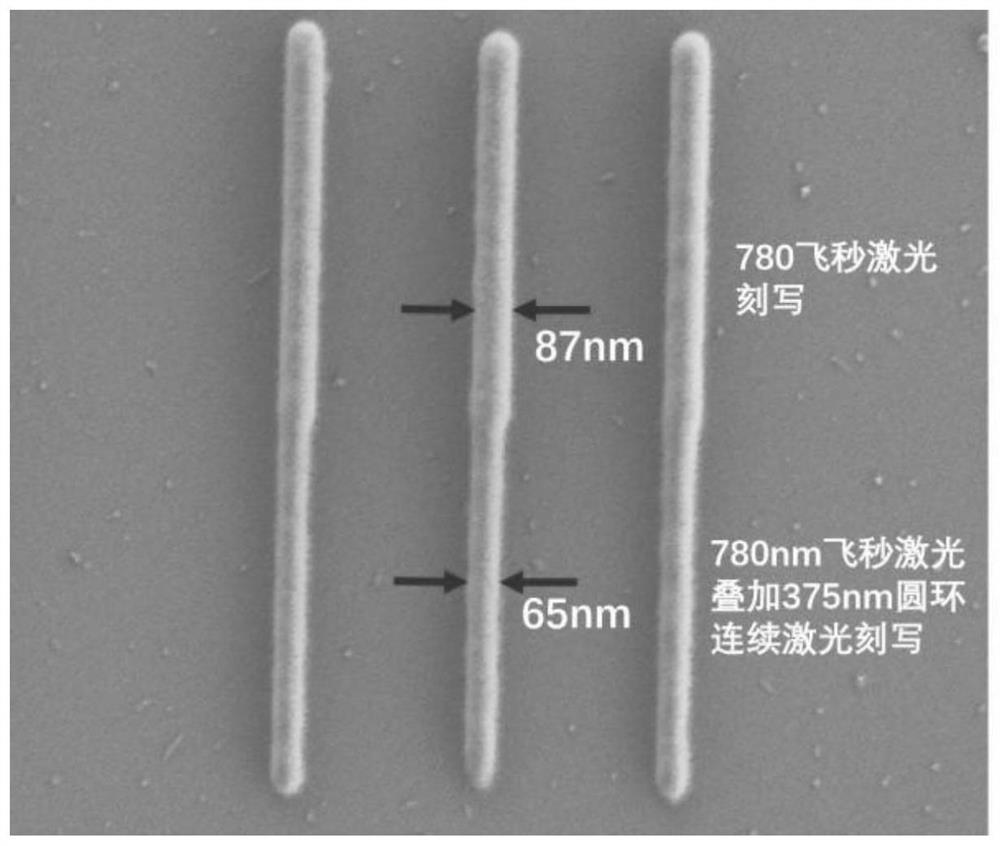

[0044] (2) Expose the photoresist by superimposing a ring-shaped continuous laser with a femtosecond laser, wherein the wavelength λ1 is 300nm; the wavelength λ2 is 700nm, the laser pulse of the femtosecond laser is preferably 80fs, and the repetition frequency is preferably 60MHz.

[0045] (3) Develop the exposed silicon wafer in γ-butyrolactone ...

Embodiment 2

[0048] In the yellow light chamber, mix and stir the reversible photoinitiator A-2 and resin B-2 evenly according to the ratio of experiment 3 and experiment 4 in the following table 1; after filtering out impurities with a filter membrane, an intelligent reversible photosensitive femtosecond laser light is obtained. Engraving.

[0049] (1) Take the intelligent femtosecond laser photoresist composition and drop it on a 2-inch glass plate, and use a homogenizer to spin-coat to prepare a photoresist film. The homogenization process adopts a programmed speed increase, specifically: 10s at 500 rpm, 10s at 2000 rpm, and 120s at 5000 rpm.

[0050] (2) Expose the photoresist by superimposing a ring-shaped continuous laser with a femtosecond laser, wherein the wavelength λ1 is 440nm; the wavelength λ2 is 800nm. The laser pulse of the femtosecond laser is preferably 100fs, and the repetition frequency is preferably 80MHz.

[0051] (3) Develop the exposed glass sheet in propylene glyco...

Embodiment 3

[0054] In the yellow light chamber, mix and stir the reversible photoinitiator A-1 / A-2 composition and resin B-2 according to the ratio of experiment 5 and experiment 6 in the following table 1; filter out impurities with a filter membrane to obtain an intelligent reversible Photosensitive femtosecond laser photoresists.

[0055] (2) Take the intelligent femtosecond laser photoresist composition and drop it on a 2-inch quartz plate, and use a homogenizer to spin-coat to prepare a photoresist film. The homogenization process adopts a programmed speed increase, specifically: 1000 rpm for 10 s, 4000 rpm for 10 s, and 8000 rpm for 120 s.

[0056] (2) Expose the photoresist by superimposing a ring-shaped continuous laser with a femtosecond laser, the middle wavelength λ1 is 550nm; the wavelength λ2 is 1000nm, the laser pulse of the femtosecond laser is preferably 120fs, and the repetition frequency is preferably 100MHz.

[0057] (3) Develop the exposed quartz plate in isopropanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com