Ternary positive electrode slurry and preparation method thereof

A technology of positive electrode slurry and positive electrode material, which is applied in the field of ternary positive electrode slurry and its preparation, can solve the problems of long dispersion time of ternary slurry, high comprehensive cost, easy agglomeration, etc., and achieve saving glue time and good mixing effect, short-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

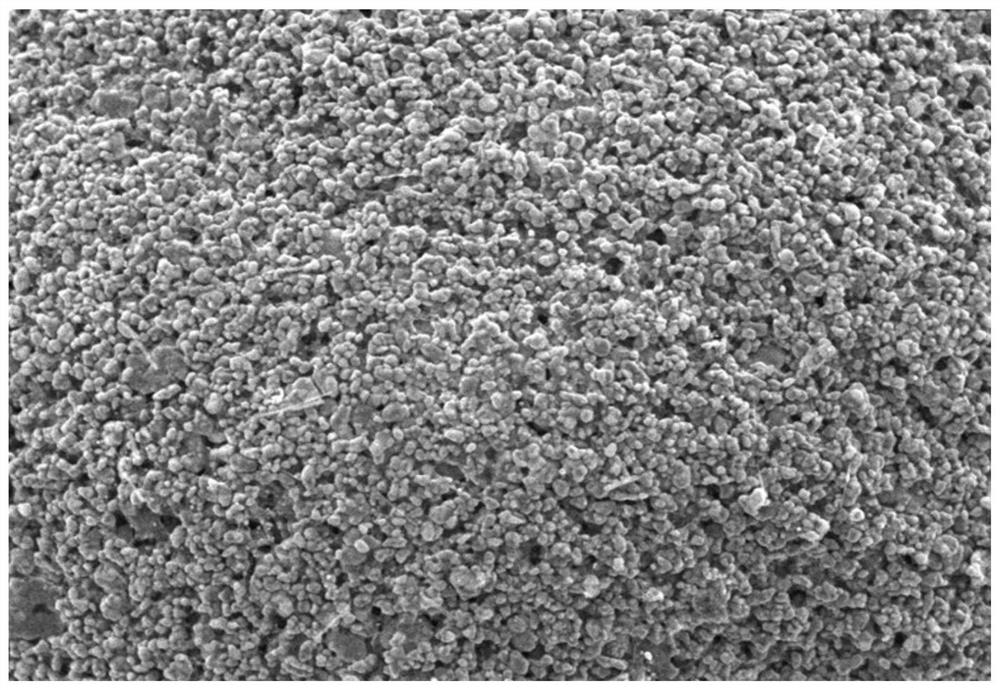

Image

Examples

preparation example Construction

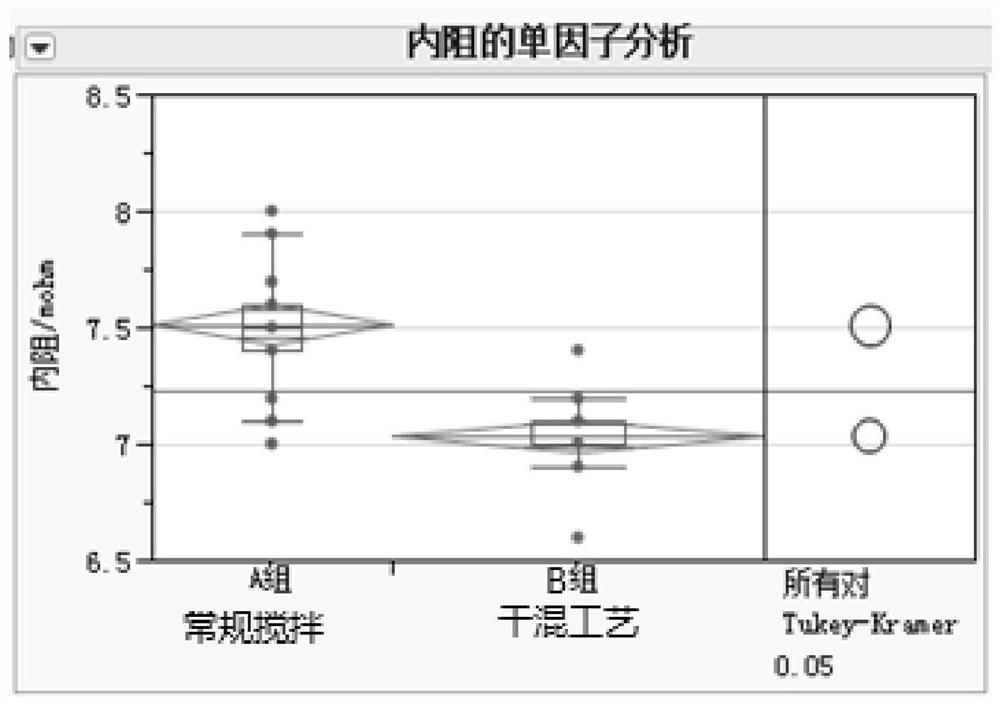

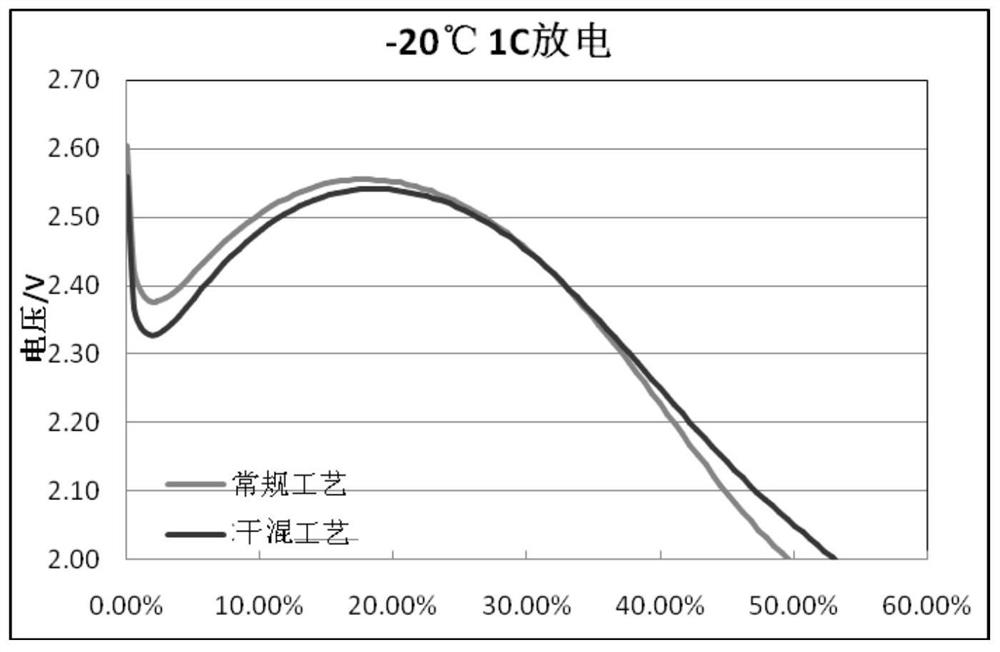

[0030] The embodiment of the present disclosure provides a preparation method of a ternary positive electrode slurry, which includes: first mixing and stirring the ternary positive electrode material and the binder for 5-60 minutes, then adding a solvent and continuing to stir, and finally adding a conductive agent and continuing to stir for 30- After 240 minutes, the ternary cathode slurry was obtained. Wherein, the binder is added in a powder state. The conductive agent includes but not limited to SP (super pll conductive carbon black), KS-6 (graphite conductive agent), ECP (Ketjen black).

[0031] In the embodiment of the present invention, since the specific surface area of the ternary positive electrode material is much smaller than that of the conductive agent, the ternary positive electrode material is added first, and the viscosity of the slurry is low, which is more conducive to dispersion. In addition, the stirring binder PVDF is added in a powder state, which sav...

Embodiment 1

[0034] The ternary cathode slurry of the present embodiment and its preparation method comprise the following steps:

[0035] (1) Add the ternary positive electrode material, binder PVDF, and conductor agent powder into the mixing tank, rotate at 150 rpm, revolution at 40 rpm, and stir for 15 minutes.

[0036] (2) Add all the NMP solvent, turn on the cooling water, rotate at 200rpm, revolution at 40rpm, stir for 40min, and scrape the material after stirring.

[0037] (3) The rotation is 1200 rpm, the revolution is 40 rpm, and stirring is continued for 40 minutes.

[0038] (4) Add SP and KS-6 conductive agent and stir for 30 minutes, and scrape the material after stirring.

[0039] (5) The rotation is 1400rpm, the revolution is 40rpm, and the vacuum degree is ≤-0.09MPa. After stirring for 60 minutes, scrape the material and continue stirring for 120 minutes.

[0040] (6) Turn off the rotation, adjust the revolution frequency to 25rpm and stir slowly for 30min for vacuum degas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com