A kind of nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

A cathode material, nickel-cobalt-manganese technology, applied in the field of lithium-ion battery nickel-cobalt-manganese ternary cathode material and its preparation, which can solve the problem of easy structural peeling and collapse between grain boundaries, reduction of battery energy density, and reduction of high-temperature storage performance, etc. problems, to achieve the effect of improving structural stability and high temperature cycle performance, improving compactness and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

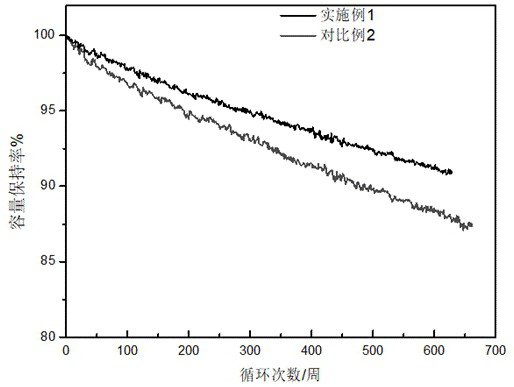

Embodiment 1

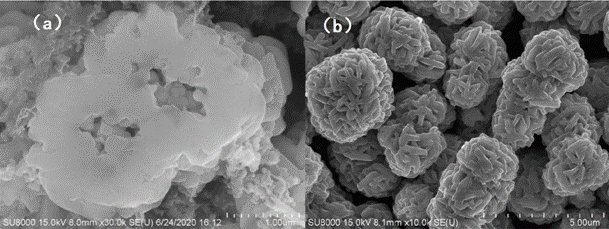

[0029] A kind of nickel-cobalt-manganese ternary cathode material of the present invention, its molecular formula is Li(Ni 0.6 co 0.2 mn 0.2 ) 0.98 W 0.02 o 2 , the material is a twinned or triplet hollow structure with a particle size D50 of 3.75 μm.

[0030] A preparation method of the nickel-cobalt-manganese ternary positive electrode material of the present embodiment, comprising the steps of:

[0031] (1) The hollow precursor Ni with a particle diameter of 1.5-3.0 μm 0.6 co 0.2 mn 0.2 (OH) 2 Add it into the aqueous solution containing ammonia water and NaOH and mix it. The concentration of ammonia water is controlled to be 3-4g / L, the pH is controlled to be 11.3-11.6, the stirring speed is 500rpm, and it is reacted at a constant temperature of 60-63°C for 10h, filtered, washed, After drying, a twin or triple ecological hollow precursor with a particle size D50 of 3.5 μm is obtained;

[0032] (2) LiOH·H 2 O and the resulting precursor and WO 3 Mix according to ...

Embodiment 2

[0035] A kind of nickel-cobalt-manganese ternary cathode material of the present invention, its molecular formula is Li(Ni 0.6 co 0.2 mn 0.2 ) 0.99 B 0.01 o 2 , the material is twin or triple hollow structure, particle size D50 is 3.88μm.

[0036] A preparation method of the nickel-cobalt-manganese ternary positive electrode material of the present embodiment, comprising the steps of:

[0037] (1) The hollow precursor Ni with a particle diameter of 1.5-3.0 μm 0.6 co 0.2 mn 0.2 (OH) 2 Add it into the aqueous solution containing ammonia water and NaOH and mix it. The concentration of ammonia water is controlled to be 3-4g / L, the pH is controlled to be 11.3-11.6, the stirring speed is 500rpm, and it is reacted at a constant temperature of 60-63°C for 10h, filtered, washed, After drying, a twin or triple ecological hollow precursor with a particle size D50 of 3.5 μm is obtained;

[0038] (2) LiOH·H 2 O with the resulting precursor and H 3 BO 3 Mix according to the molar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com