Light bipolar lead-acid battery grid and preparation method thereof

A lead-acid battery, bipolar technology, applied in bipolar electrodes, battery electrodes, active material electrodes, etc., to achieve low resistivity, improve weight specific energy and power characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

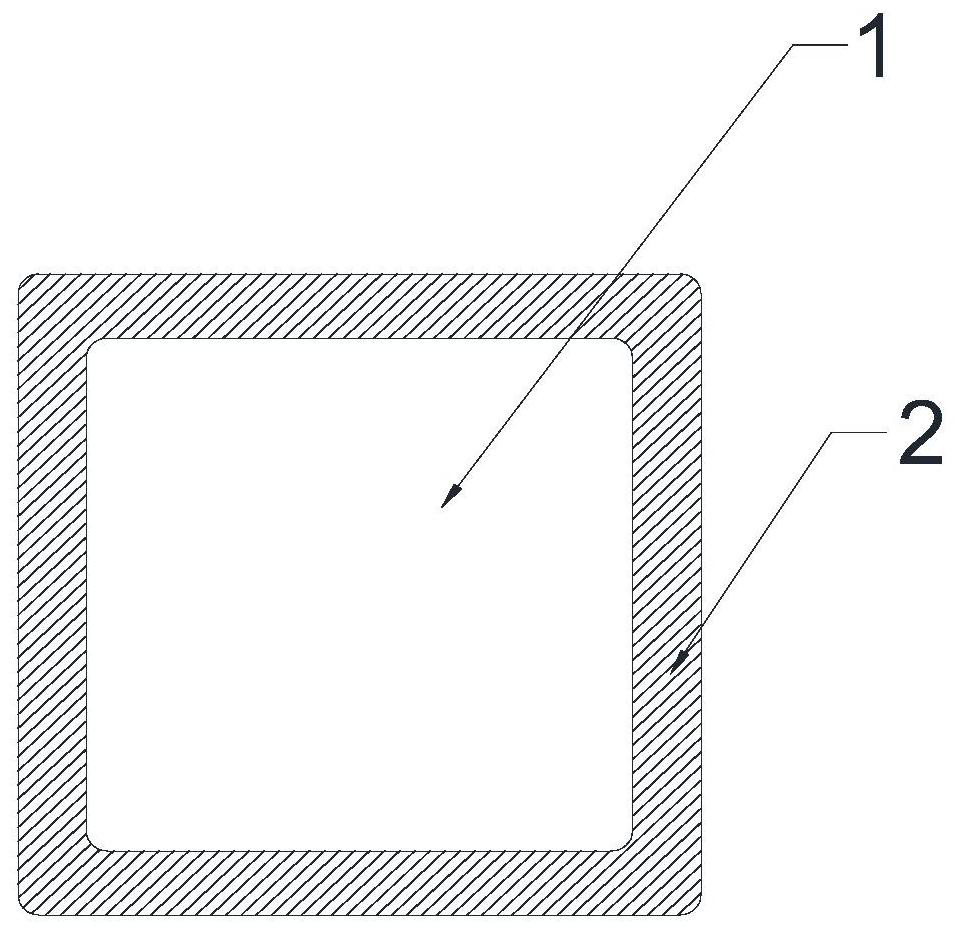

Image

Examples

Embodiment 1

[0029] Weigh 1460g BaCO 3 with 1180g Pb 3 o 4 For the sample, weigh 60g of fumed silica and 20g of ytterbium fluoride at the same time, use a planetary ball mill at 1000 rpm, grind and mix for 10min, put the above powder into the mold, the cavity size of the mold is 100mm × 100mm, and the thickness of the substrate cavity is 0.5mm, frame thickness 10mm, mold clamping pressure value 0.5MPa, material is stainless steel, put into muffle furnace after fixing, in air atmosphere and temperature 1000℃, time is 5h. After cooling down naturally, open the mold, take out the plate, and remove the burrs.

[0030] The pressed barium lead acid sintered plate is used as the working electrode, the pure lead plate is used as the counter electrode, the aqueous solution of 10% lead nitrate and 35% sulfuric acid is used as the electrolyte, and the Hg / Hg 2 SO 4 / H 2 SO 4 As a reference electrode, use the constant potential method to conduct cathodic polarization at the potential of -1.1V for...

Embodiment 2

[0054] Weigh 1460g BaCO 3 with 1180g Pb 3 o 4 For the sample, weigh 60g of fumed silica and 20g of ytterbium fluoride at the same time, use a planetary ball mill at 1000 rpm, grind and mix for 10min, put the above powder into the mold, the cavity size of the mold is 150mm × 150mm, and the thickness of the substrate cavity is 1mm, frame thickness 10mm, mold clamping pressure value 0.8Mpa, material is stainless steel, put into muffle furnace after fixing, in air atmosphere and temperature 1000℃, time is 6h. After cooling down naturally, open the mold, take out the plate, and remove the burrs.

[0055] The pressed barium lead acid sintered plate is used as the working electrode, the pure lead plate is used as the counter electrode, the aqueous solution of 10% lead nitrate and 35% sulfuric acid is used as the electrolyte, and the Hg / Hg 2 SO 4 / H 2 SO 4 As a reference electrode, use the constant potential method to conduct cathodic polarization at the potential of -1.1V for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com