Control method of liquid hydrogen fuel cell waste heat recovery system

A waste heat recovery system and fuel cell technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problem of reducing cooling fans, etc., to achieve the effects of reducing noise, making full use of it, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

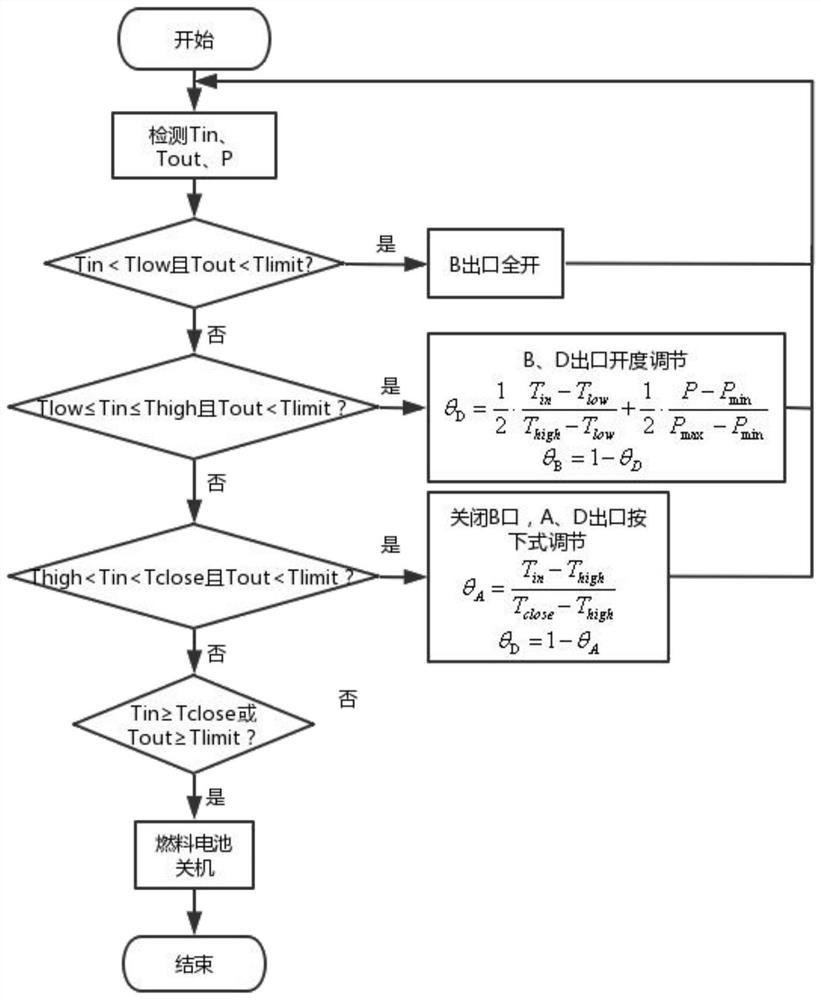

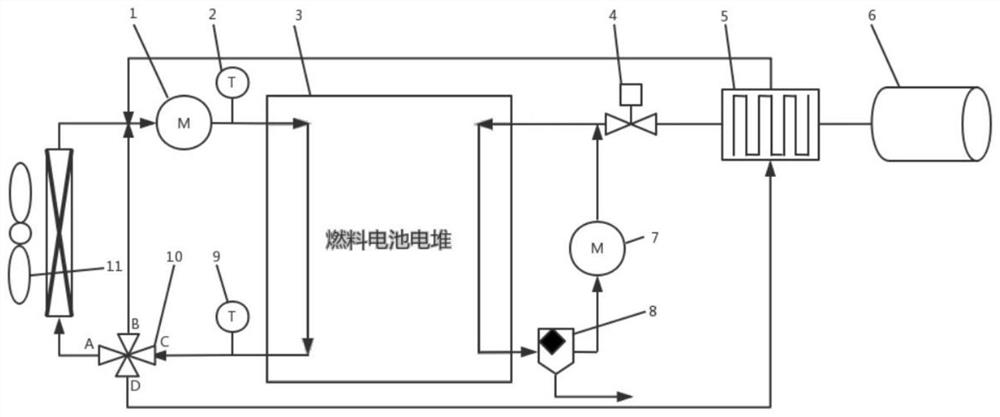

[0036] In this example, see figure 1 and figure 2As shown, the present invention proposes a control method for a liquid hydrogen fuel cell waste heat recovery system. The liquid hydrogen fuel cell waste heat recovery system includes: the fuel cell stack 3 coolant outlet is connected to the stack coolant outlet temperature sensor 9 to the four-way The inlet of the valve 10C and the outlet of the four-way valve 10A are connected to the cooling liquid inlet of the cooling fan 11, the cooling liquid outlet of the cooling fan 11 is combined with the cooling liquid output by the heat exchanger 5, and the B outlet of the four-way valve 10 is input into the cooling water pump 1 inlet, and the cooling water pump 1 outlet is connected to the stack coolant inlet temperature sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com