Vertically-assembled PCBA board based on wave soldering and electronic component

A vertical assembly, wave soldering technology, applied in the field of identification, can solve the problem that PCBA does not support wave soldering, etc., to achieve good soldering quality, ensure soldering quality, and improve soldering efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

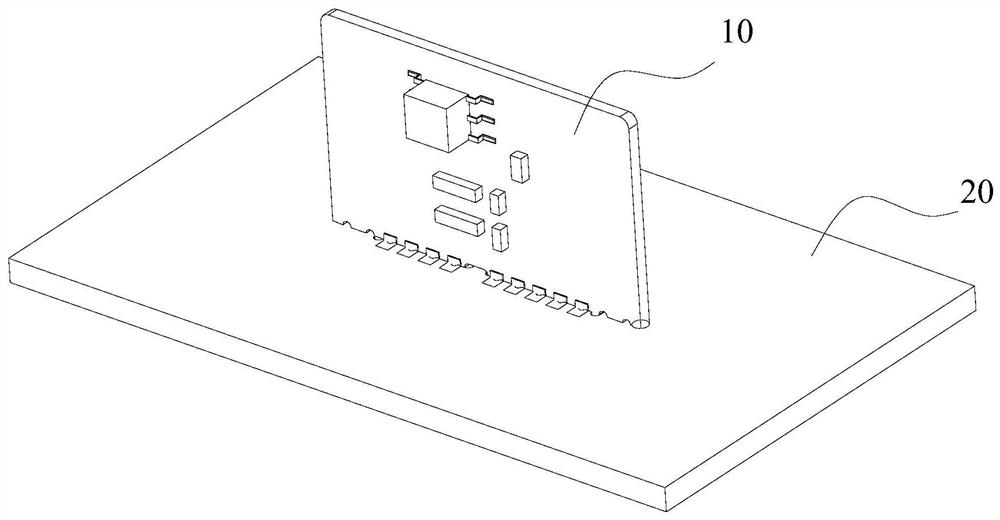

[0029] figure 1 It is a structural schematic diagram of a vertically assembled PCBA board based on wave soldering under the first perspective provided by Embodiment 1 of the present application. refer to figure 1 , vertically assembling the PCBA board includes: a PCBA sub-board 10 and a PCBA bottom board 20 , and the PCBA sub-board 10 is vertically installed on the PCBA bottom board 20 .

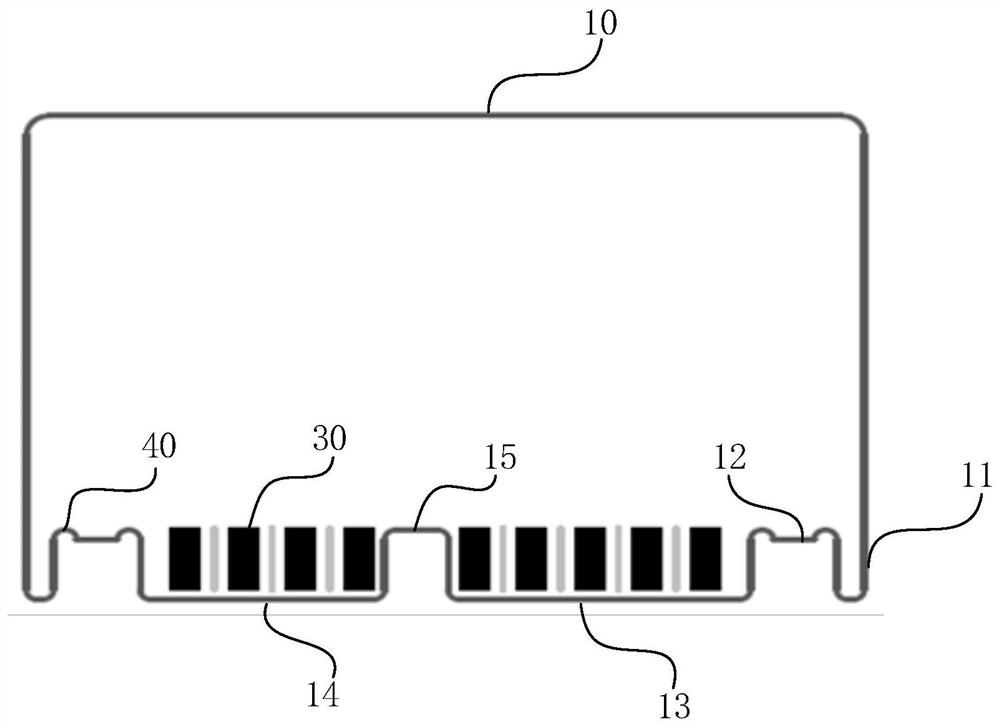

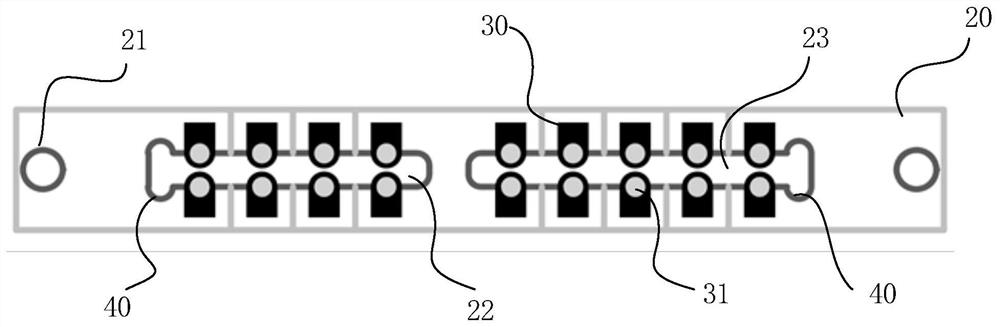

[0030] specific, figure 2 It is a schematic structural diagram of a PCBA sub-board 10 provided in Embodiment 1 of the present application. refer to figure 2 , the two ends of the first edge of the PCBA sub-board 10 are provided with fixed pins 11, the middle of the first edge is provided with a mounting plate, and a first opening 12 is provided between the fixed pins 11 and the mounting plate , the mounting board includes a first welding area 14 and a second welding area 13, both sides of the first welding area 14 and the second welding area 13 are provided with pads 30, the first weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com