Fault-tolerant control system and method applied to magnetic suspension high-speed blower

A fault-tolerant control and blower technology, which is applied in the control system, vector control system, motor control, etc., can solve problems such as damage, angular position sensor performance impact, and normal operation of the blower, so as to enhance stability and meet the needs of fault-tolerant control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Next, the technical solutions in the embodiments of the present invention will be described in the embodiment of the present invention, which is apparent from the embodiments of the present invention, and is apparent from the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art will belong to the scope of the present invention without paying creative labor.

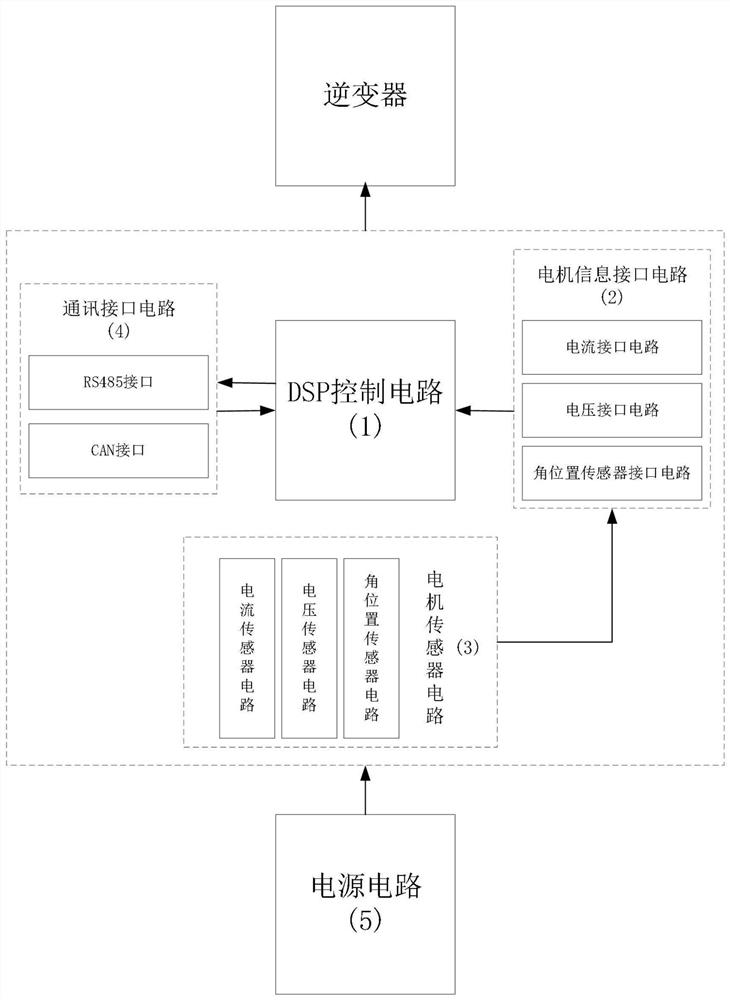

[0033] like figure 1 As shown, the fault-tolerant control system of the present invention mainly includes a DSP control circuit (1), a motor information interface circuit (2), the motor sensor circuit (3), the communication interface circuit (4), and the power supply circuit (5). Where the DSP control circuit (1) is the system core circuit, connected to the motor information interface circuit (2), the communication interface circuit (4).

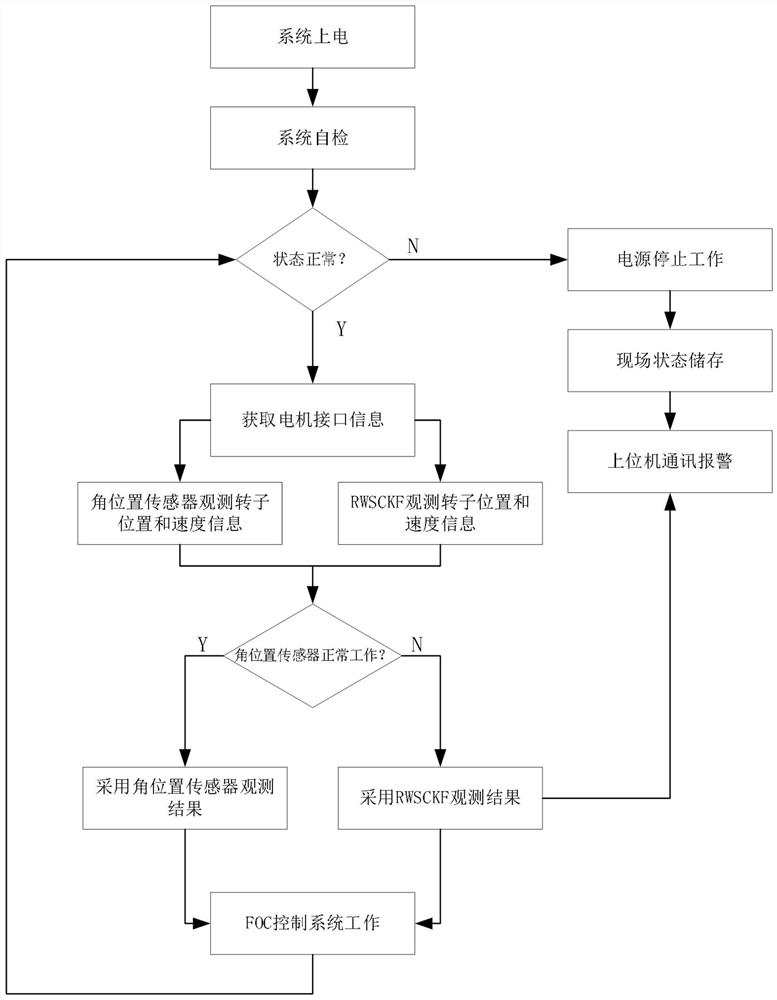

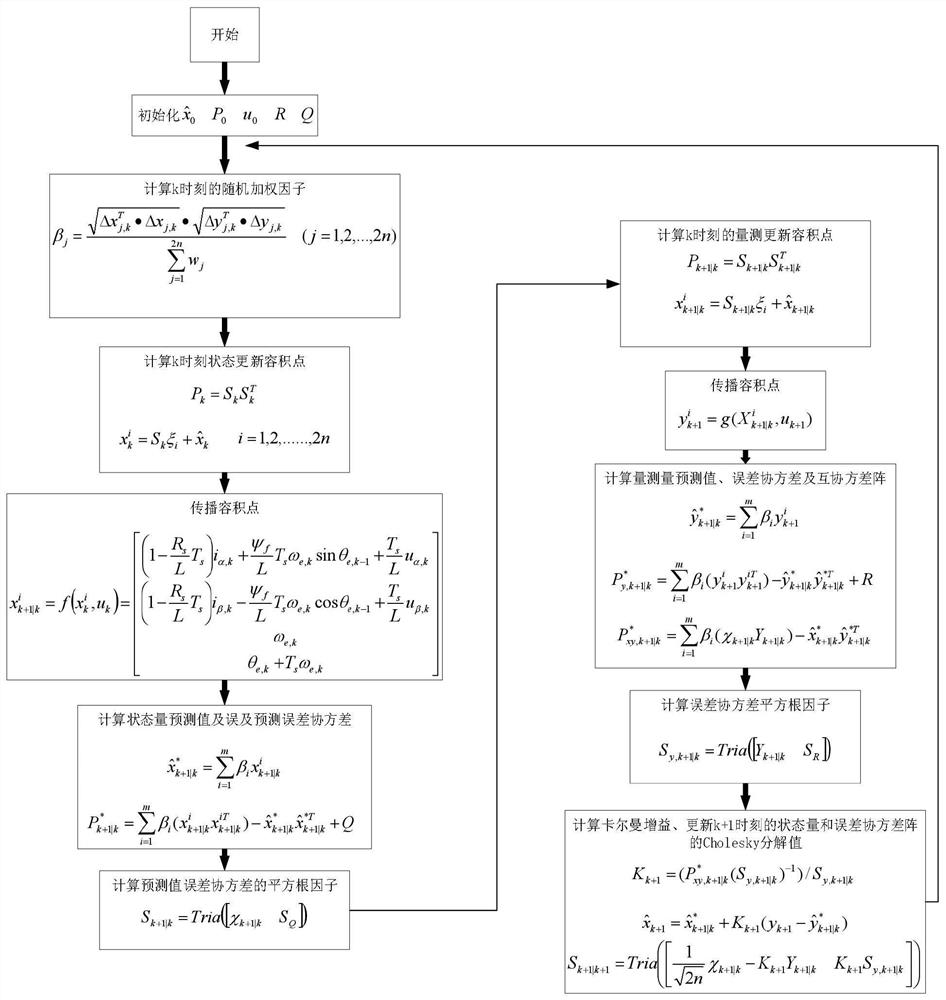

[0034] The magnetic field orientation control FOC algorithm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com