Composite wave-absorbing material with rare earth element-doped magnetic particles loaded on layered MXene

A composite wave-absorbing material and rare earth element technology, which is applied in the direction of electrical components, magnetic/electric field shielding, and carbides, can solve the problems of high density, narrow wave-absorbing frequency bandwidth, and single type, and achieve simple preparation methods and improved absorption Wave performance, absorption bandwidth, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

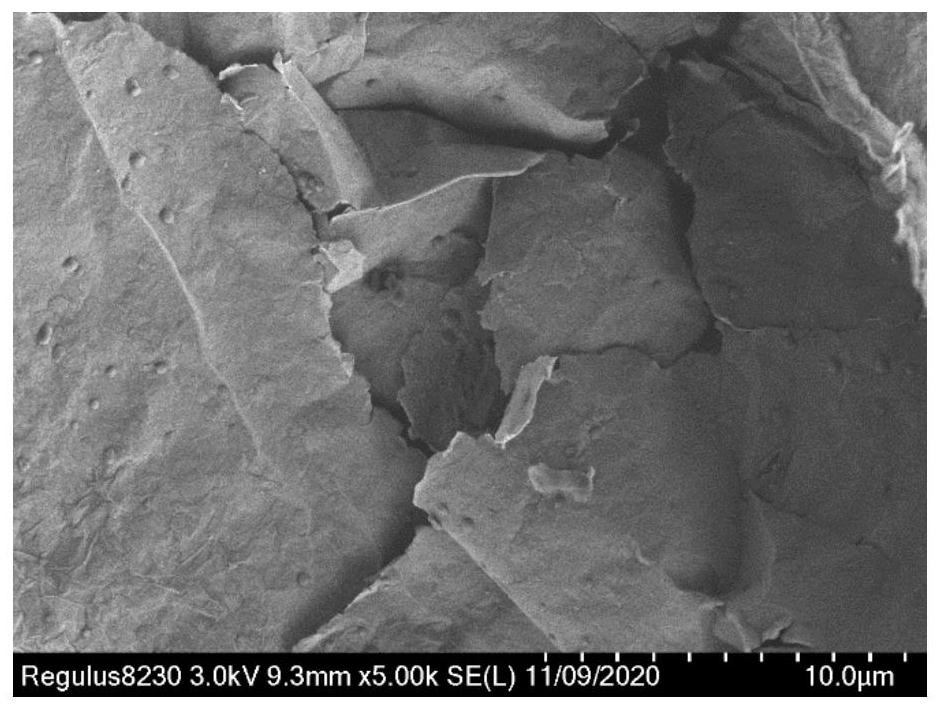

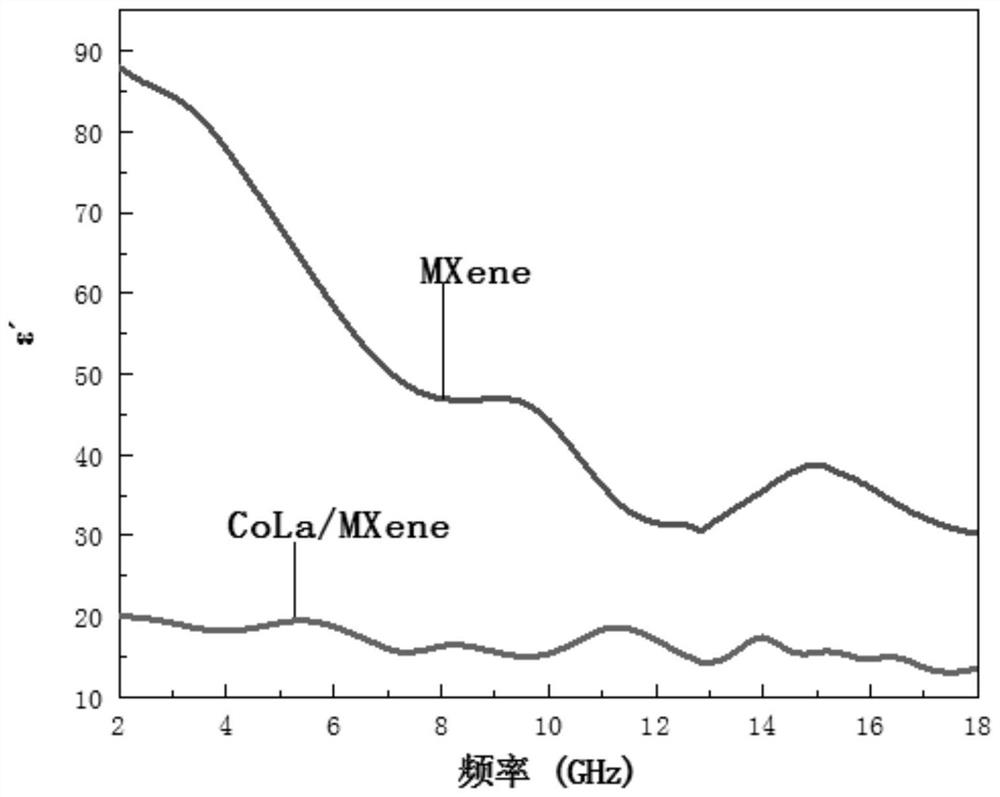

[0085] Preparation of MXene: Prepare 20ml of 9M hydrochloric acid solution, pour it into a 50ml polypropylene bottle, add 1g of lithium fluoride and stir evenly. Weigh again 1g MAX phase (Ti 3 AlC 2 ) powder, slowly added to the mixed solution, stirred and reacted at 35°C for 48h. After the reaction is completed, wash with deionized water until neutral, stir in 150ml of water for 1h, cryogenically sonicate for 1h under nitrogen protection, and then centrifuge at a speed of 3500r / m for 1h, and take the upper liquid to freeze-dry to obtain layered MXene powder. looks like figure 1 shown.

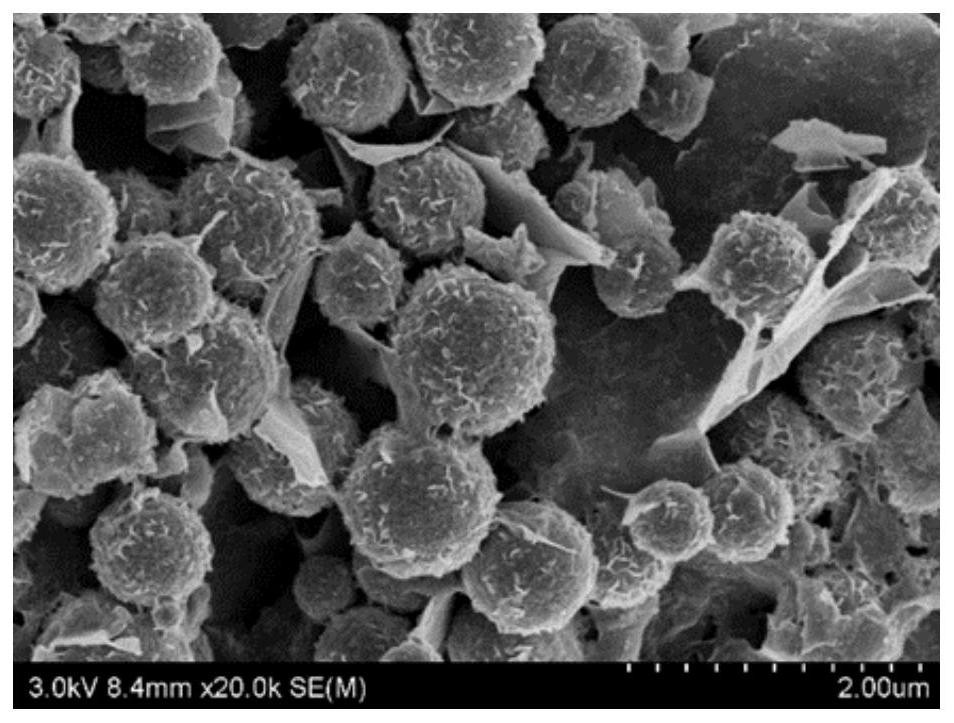

[0086] Preparation of CoLa / MXene: Weigh 90 mg of the MXene powder obtained above, add it into a mixed solution of 5 ml water and 45 ml ethylene glycol, and stir in a conical flask for 15 min. Take 1.3gCoCl respectively 2 ·6H 2 O and 0.097g LaCl 3 ·6H 2 O was added to the above solution and stirred for 15 min, and then 1.2 g of NaOH was used to adjust the pH to make the solution reach a...

Embodiment 2

[0088] Preparation of MXene: prepare 40ml of 9M hydrochloric acid solution, pour it into a 50ml polypropylene bottle, add 2g of lithium fluoride and stir evenly. Weigh again 2g MAX phase (Ti 3 AlC 2 ) powder, slowly added to the mixed solution, stirred and reacted at 40°C for 48h. After the reaction was completed, wash with deionized water until neutral, stir in 200ml of water for 1h, cryogenically sonicate for 1.5h under nitrogen protection, then centrifuge at 4000r / m for 1h, take the upper liquid and freeze-dry to obtain layered MXene powder.

[0089]Preparation of FeLa / MXene: Weigh 90 mg of the MXene powder obtained above, add it into a mixed solution of 5 ml water and 45 ml ethylene glycol, and stir in a conical flask for 15 min. Take 1.14gFeCl respectively 2 4H 2 O and 0.097g LaCl 3 ·6H 2 O was added to the above solution and stirred for 15 min, then 1.2 g of NaOH was used to adjust the pH to make the solution highly alkaline, and then 4 ml of hydrazine hydrate was ...

Embodiment 3

[0091] Preparation of MXene: Prepare 20ml of 9M hydrochloric acid solution, pour it into a 50ml polypropylene bottle, add 1g of lithium fluoride and stir evenly. Weigh again 1g MAX phase (Ti 3 AlC 2 ) powder, slowly added to the mixed solution, stirred and reacted at 35°C for 24h. After the reaction was completed, wash with deionized water until neutral, stir in 150ml of water for 1h, cryogenically sonicate for 1h under nitrogen protection, then centrifuge at 3500r / m for 1.5h, take the upper liquid and freeze-dry to obtain layered MXene powder.

[0092] Preparation of CoLa / MXene: Weigh 90 mg of the MXene powder obtained above, add to a mixed solution of 10 ml of water and 40 ml of ethylene glycol, and stir in a conical flask for 15 min. Take 0.65gCoCl respectively 2 ·6H 2 O and 0.048g LaCl 3 ·6H 2 O was added to the above solution and stirred for 15 minutes, and then 1 g of NaOH was used to adjust the pH, so that the solution reached a strong alkalinity, and then 2.5 ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Return loss | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com