Low-temperature quaternary ammonium salt disinfectant and preparation method thereof

A quaternary ammonium salt and disinfectant technology, which is applied in the field of low-temperature quaternary ammonium salt disinfectant and its preparation, can solve problems such as failing to meet disinfection requirements, and achieve environmental and biological safety, good stability, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

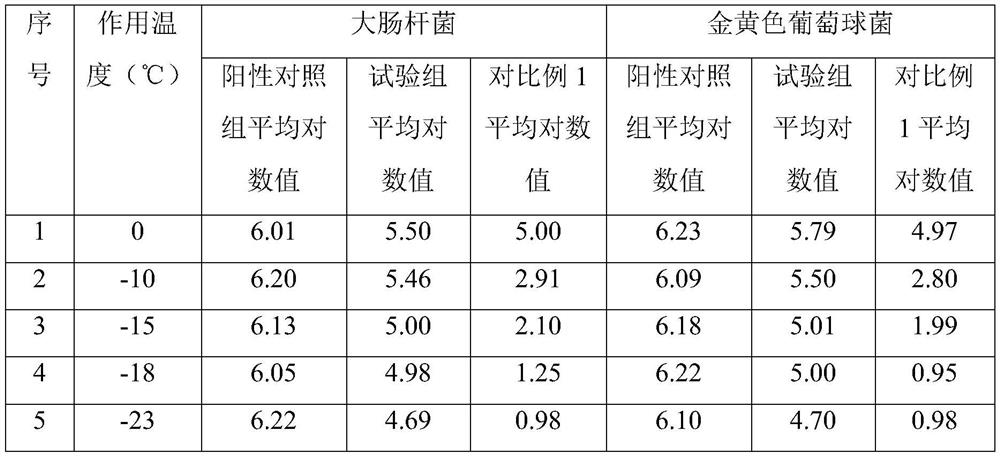

Examples

Embodiment 1

[0038] A preparation method of low-temperature quaternary ammonium salt disinfectant, comprising the following steps:

[0039] S1. Weigh 0.5g of octyldecyldimethylammonium chloride, 0.5g of didecyldimethylammonium chloride, 4g of polydimethylsiloxane, 6g of Tween, dodecyldimethyl ammonium chloride 2.5g of amine, 2.5g of alkyl glycoside, 200g of ethanol and 784g of water;

[0040] S2. water is mixed with quaternary ammonium salt, stirred at 30rpm / min for 30min;

[0041] S3. Mix polydimethylsiloxane and Tween in advance, then add to the solution obtained in step S2, and stir at 30rpm / min for 30min;

[0042] S4. Dodecyl dimethyl amine oxide and alkyl glucoside are pre-mixed, then added to the mixed solution obtained in step S3, stirred at 30rpm / min for 15min;

[0043] S5. Add ethanol to the mixed solution obtained in step S4, and stir at 30 rpm / min for 20 min to obtain.

Embodiment 2

[0045] A preparation method of low-temperature quaternary ammonium salt disinfectant, comprising the following steps:

[0046] S1. Weigh 3 g of octyl decyl dimethyl ammonium chloride, 3 g of didecyl dimethyl ammonium chloride, 20 g of polydimethylsiloxane, 30 g of Tween, 0.3 g of dodecyl dimethyl amine oxide g, 0.7g of alkyl glucoside, 500g of ethanol and 443g of water;

[0047] S2. water is mixed with quaternary ammonium salt, stirred at 30rpm / min for 30min;

[0048] S3. Mix polydimethylsiloxane and Tween in advance, then add to the solution obtained in step S2, and stir at 30rpm / min for 30min;

[0049] S4. Dodecyl dimethyl amine oxide and alkyl glucoside are pre-mixed, then added to the mixed solution obtained in step S3, stirred at 30rpm / min for 15min;

[0050] S5. Add ethanol to the mixed solution obtained in step S4, and stir at 30 rpm / min for 20 min to obtain.

Embodiment 3

[0052] A preparation method of low-temperature quaternary ammonium salt disinfectant, comprising the following steps:

[0053]S1. Weigh 2 g of octyl decyl dimethyl ammonium chloride, 2 g of didecyl dimethyl ammonium chloride, 4 g of polydimethylsiloxane, 6 g of Tween, and 1.5 g of dodecyl dimethyl ammonium oxide. g, 3.5g of alkyl glucoside, 300g of ethanol and 681g of water;

[0054] S2. water is mixed with quaternary ammonium salt, stirred at 30rpm / min for 30min;

[0055] S3. Mix polydimethylsiloxane and Tween in advance, then add to the solution obtained in step S2, and stir at 30rpm / min for 30min;

[0056] S4. Dodecyl dimethyl amine oxide and alkyl glucoside are pre-mixed, then added to the mixed solution obtained in step S3, stirred at 30rpm / min for 15min;

[0057] S5. Add ethanol to the mixed solution obtained in step S4, and stir at 30 rpm / min for 20 min to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com