Steel rail crawling online monitoring terminal, system and method

A monitoring terminal and monitoring system technology, applied in signal transmission systems, image data processing, instruments, etc., can solve the problems of difficult maintenance and hidden dangers of line safety, and achieve the effect of high safety and favorable promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] as attached Figure 4 As shown, an embodiment of the rail crawling online monitoring terminal of the present invention specifically includes: a camera component 11 , an image processing unit 12 , a signal acquisition unit 13 , a communication unit 14 , a temperature measuring sensor 15 and a light source 16 . The camera component 11 shoots (collects) images (pictures) containing the measurement marker 4 , and the image processing unit 12 calculates the position information of the measurement marker 4 based on the image captured by the camera component 11 and sends it to the signal acquisition unit 13 . The light source 16 is used to supplement the light for the image capture of the measurement mark 4 by triggering the signal acquisition unit 13 under weak light conditions (such as at night or in dark environments such as tunnels and canyons). The light source 16 can use LEDs (Light Emitting Diode, short for light-emitting diode) module. The signal acquisition unit 13 c...

Embodiment 2

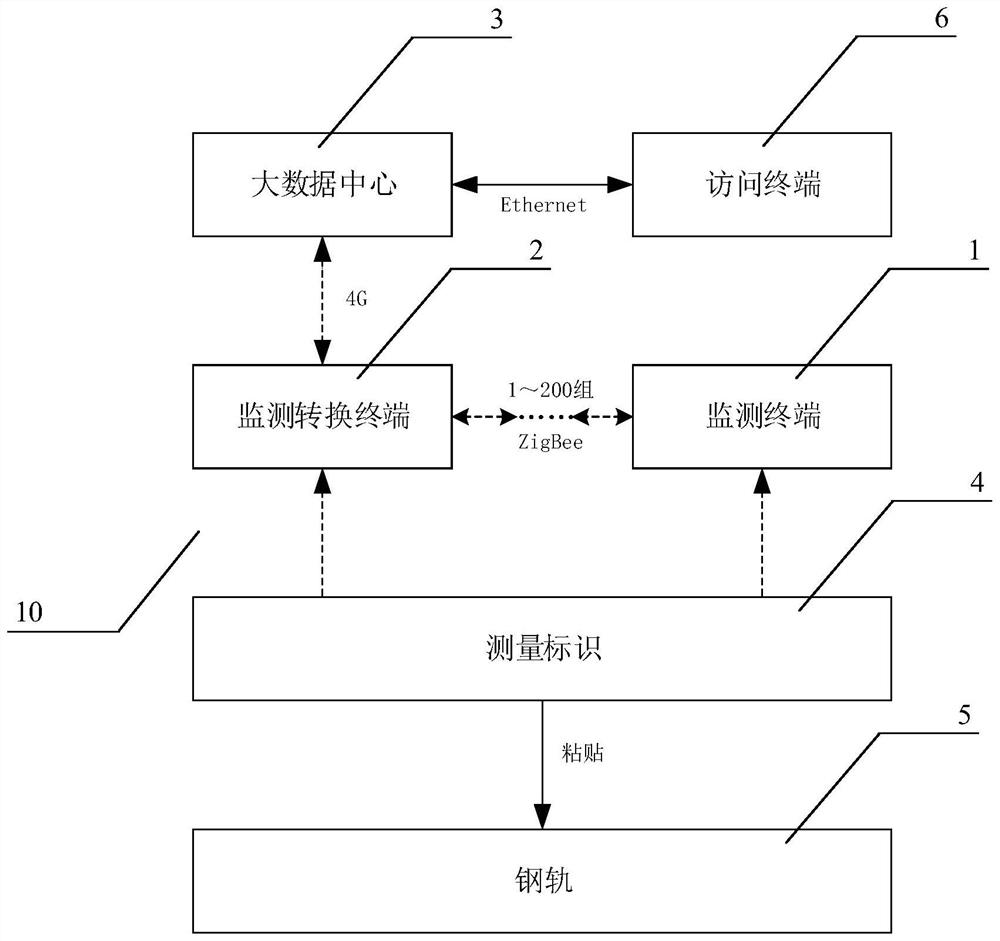

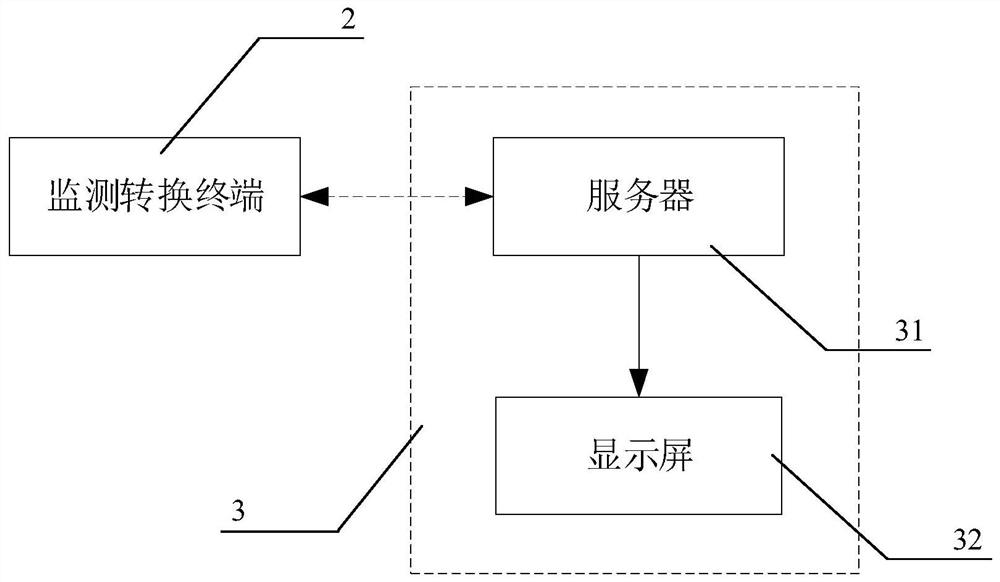

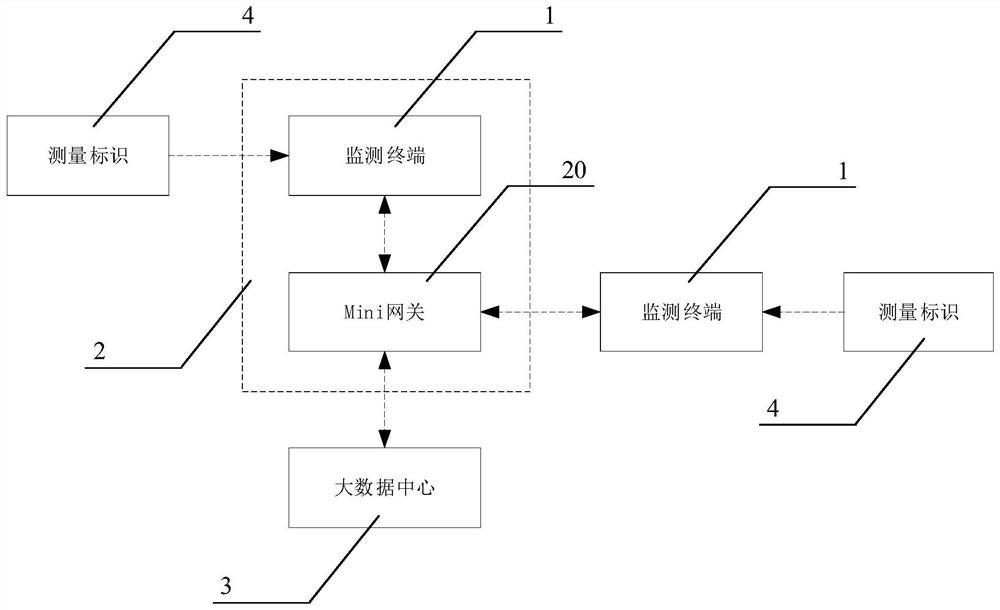

[0070] as attached figure 1 As shown, an embodiment of the rail crawling online monitoring system 10 of the present invention specifically includes: a monitoring conversion terminal 2, a big data center 3, a measurement identification 4, an access terminal 6, and more than one monitoring terminal as described in Embodiment 1 1 (for example, 1 to 200 groups of monitoring terminals 1 can be used to realize interconnection through Zigbee). The measurement mark 4 is fixedly connected to the rail 5 to represent the position of the rail 5, and the monitoring terminal 1 and the monitoring conversion terminal 2 realize the crawling amount and temperature measurement of the rail 5 and are interconnected through a wireless communication network (such as Zigbee or LoRa network). The monitoring conversion terminal 2 packages the wireless data (such as Zigbee or LoRa data) in the same network IP (Internet Protocol, the abbreviation of Internet Protocol), and uploads to the big data center ...

Embodiment 3

[0078] An embodiment of the online rail crawling monitoring method of the present invention, the monitoring terminal 1 includes a camera component 11 , an image processing unit 12 , a signal acquisition unit 13 , a communication unit 14 , a temperature measuring sensor 15 and a light source 16 . The rail crawling online monitoring method specifically includes the following steps:

[0079] S10) The measurement mark 4 is fixedly connected to the rail 5, and the image containing the measurement mark 4 is taken by the camera assembly 11;

[0080] S20) The image processing unit 12 calculates the position information of the measurement mark 4 according to the image taken by the camera assembly 11 and then sends it to the signal acquisition unit 13; under weak light conditions, the light source 16 is triggered by the signal acquisition unit 13 to shoot the measurement mark 4. The image is filled with light;

[0081] S30) The signal acquisition unit 13 collects the rail temperature s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com