Long-chain branched polylactic acid with high melt strength and excellent processing fluidity and preparation method thereof

A technology with processing fluidity and high melt strength, applied in the field of long-chain branched polylactic acid and its preparation, can solve the problems of reduced processing performance and increased shear viscosity of polylactic acid, and achieves improved processing performance and reduced shear viscosity. , controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

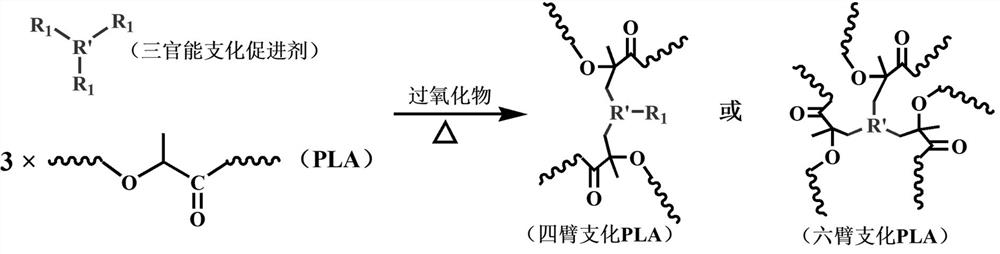

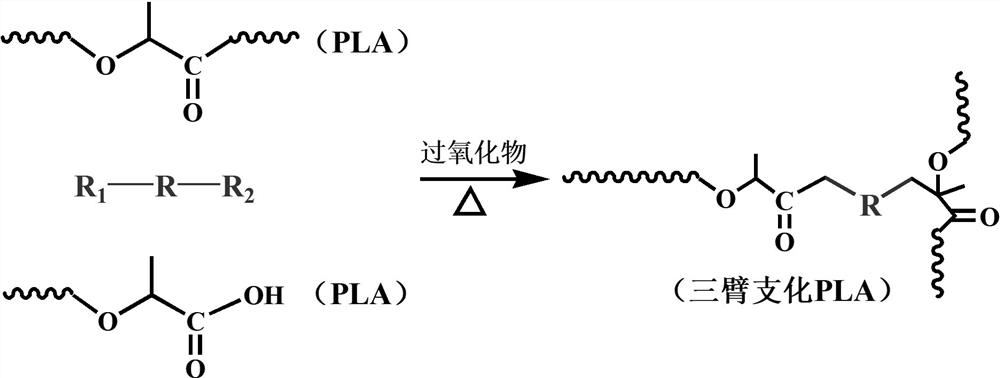

Method used

Image

Examples

Embodiment 1

[0030]In this embodiment, the preparation method of this long-chain branched polylactic acid with high melt strength and excellent processing fluidity includes the following steps in sequence:

[0031] (1) By weight, the following raw materials are equipped: 98.30% polylactic acid, 0.50% organic peroxide (tert-amyl peroxy-2-ethylhexyl carbonate), 1.20% branching regulator (4-vinylbenzyl glycidyl ether);

[0032] (2) Dry the polylactic acid at 100°C for 120 minutes to make the moisture content of the polylactic acid lower than 200ppm, and cool to 20°C;

[0033] (3) Add organic peroxides and branching regulators to polylactic acid, and mix evenly to obtain a mixed material;

[0034] (4) Melt and extrude the mixed material through a twin-screw extruder, and granulate the material extruded by the twin-screw extruder to obtain a granular long-chain compound with high melt strength and excellent processing fluidity. branched polylactic acid.

[0035] The screw aspect ratio of the...

Embodiment 2

[0039] In this embodiment, the preparation method of this long-chain branched polylactic acid with high melt strength and excellent processing fluidity includes the following steps in sequence:

[0040] (1) By weight, the following raw materials are equipped: 97.70% polylactic acid, 1.50% organic peroxide (tert-amyl peroxy-2-ethylhexyl carbonate), 1.80% branching regulator (4-vinylbenzyl glycidyl ether);

[0041] (2) Dry the polylactic acid at 115°C for 60 minutes, so that the moisture content of the polylactic acid is lower than 200ppm, and cool to 20°C;

[0042] (3) Add organic peroxides and branching regulators to polylactic acid, and mix evenly to obtain a mixed material;

[0043] (4) Melt and extrude the mixed material through a twin-screw extruder, and granulate the material extruded by the twin-screw extruder to obtain a granular long-chain compound with high melt strength and excellent processing fluidity. branched polylactic acid.

[0044] The screw aspect ratio of...

Embodiment 3

[0048] In this embodiment, the preparation method of this long-chain branched polylactic acid with high melt strength and excellent processing fluidity includes the following steps in sequence:

[0049] (1) By weight, the following raw materials are equipped: 95.80% polylactic acid, 1.20% organic peroxide (tert-amyl peroxy-2-ethylhexyl carbonate), 2.50% branching regulator (4-vinylbenzyl glycidyl ether);

[0050] (2) Dry the polylactic acid at 120°C for 80 minutes so that the moisture content of the polylactic acid is lower than 200ppm, and cool to 25°C;

[0051] (3) Add organic peroxides and branching regulators to polylactic acid, and mix evenly to obtain a mixed material;

[0052] (4) Melt and extrude the mixed material through a twin-screw extruder, and granulate the material extruded by the twin-screw extruder to obtain a granular long-chain compound with high melt strength and excellent processing fluidity. branched polylactic acid.

[0053] The screw aspect ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com