High-flexibility antistatic synthetic resin and preparation method thereof

A synthetic resin and anti-static technology, which is applied in the field of highly flexible and anti-static synthetic resin and its preparation, can solve the problems of low toughness, high cross-linking density, poor fatigue resistance and impact resistance of cured products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The second aspect of the present invention provides a method for preparing a highly flexible and antistatic synthetic resin, comprising the following specific steps:

[0030] (1) The preparation method of pre-modified bismaleimide: after the reaction of bismaleimide and allyl compound, vinyl chloride monomer is added to make it undergo chain growth on the main chain of the reactant to obtain pre-modified Sexual bismaleimide;

[0031] (2) The preparation method of modified bismaleimide: after the pre-modified bismaleimide obtained in step (1) is cooled to form a film, it is subjected to particle bombardment with graphene to obtain a modified bismaleimide to imide;

[0032] (3) The preparation method of the highly flexible antistatic synthetic resin: 50 g of the modified bismaleimide obtained in step (2) and 5 g of the curing agent were separately packaged to obtain a highly flexible antistatic synthetic resin.

[0033] Preferably, the preparation method of pre-modified...

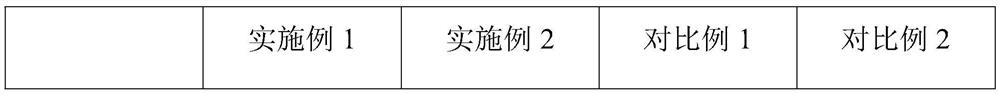

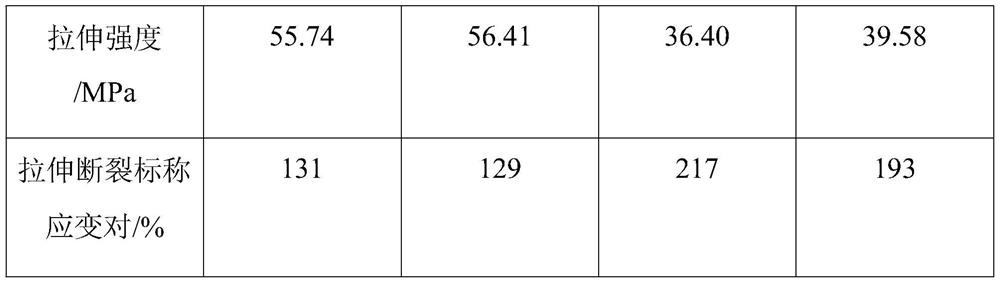

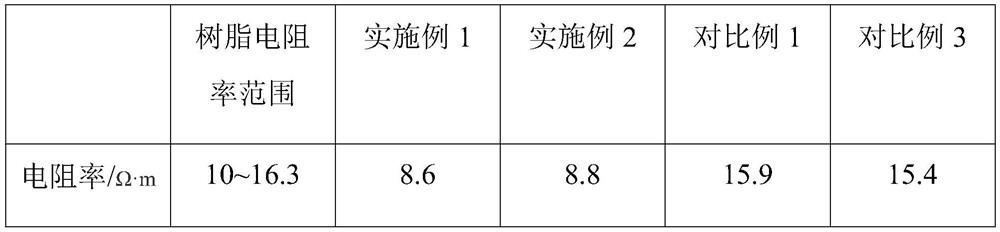

Embodiment 1

[0037] Embodiment 1: Synthetic resin with high flexibility and antistatic one:

[0038] A flexible and highly antistatic synthetic resin, the resin components are in parts by weight:

[0039] 37 parts of component one and 4 parts of component two, wherein component one is modified bismaleimide, and component two is curing agent.

[0040] The preparation method of this synthetic resin is as follows:

[0041] (1) The preparation method of pre-modified bismaleimide: after the reaction of bismaleimide and allyl compound, vinyl chloride monomer is added to make it undergo chain growth on the main chain of the reactant to obtain pre-modified Sexual bismaleimide;

[0042] (2) The preparation method of modified bismaleimide: after the pre-modified bismaleimide obtained in step (1) is cooled to form a film, it is subjected to particle bombardment with graphene to obtain a modified bismaleimide to imide;

[0043](3) The preparation method of the highly flexible antistatic synthetic ...

Embodiment 2

[0048] Embodiment 2: Synthetic resin with high flexibility and antistatic properties 2:

[0049] A flexible and highly antistatic synthetic resin, the resin components are in parts by weight:

[0050] 48 parts of component one and 5 parts of component two, wherein component one is modified bismaleimide, and component two is curing agent.

[0051] The preparation method of this synthetic resin is as follows:

[0052] (1) The preparation method of pre-modified bismaleimide: after the reaction of bismaleimide and allyl compound, vinyl chloride monomer is added to make it undergo chain growth on the main chain of the reactant to obtain pre-modified Sexual bismaleimide;

[0053] (2) The preparation method of modified bismaleimide: after the pre-modified bismaleimide obtained in step (1) is cooled to form a film, it is subjected to particle bombardment with graphene to obtain a modified bismaleimide to imide;

[0054] (3) The preparation method of the highly flexible antistatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com